Escapements and Mechanisms Case Studies

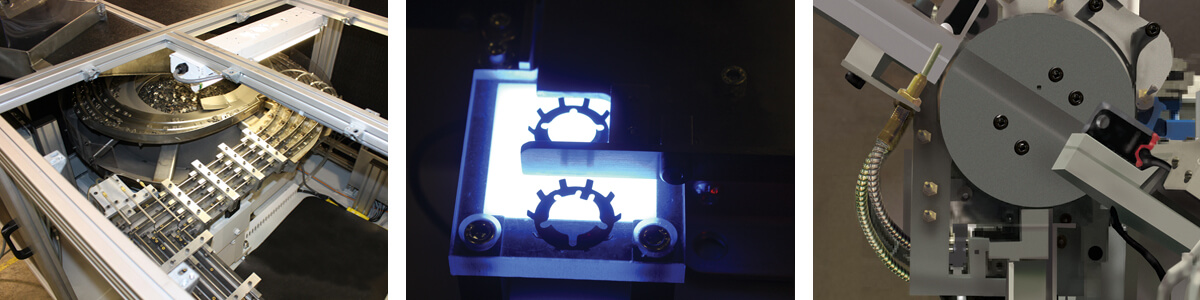

Inspection machine uses vision system logic

Problem: A manufacturer was using a two-step process to inspect and accumulate parts prior to the final machining operation. The process required double the manpower and introduced possible errors by mishandled parts. Each part was presented to a camera and another...

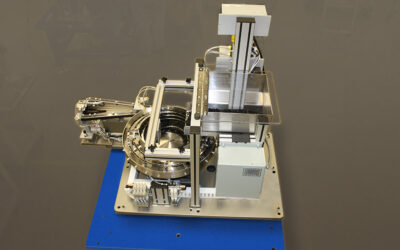

Parts feeder loads and unloads stamping press

Problem: A manufacturer of storage and shipping tubes was looking for a parts-feeding system that would work with their metal stamping unit. The parts needed to be both loaded and unloaded from the six-position stamping press every two seconds without misfeeding or...

Dual three-position shuttle for small, lightweight parts

Problem: An integrator was looking for a way to feed tiny plunger parts. The parts had a flat, oblong head with a hole running through the length of the head. The parts needed to be presented to four pickup positions with the heads up and the holes facing forward. ...

Two-for-one parts feeder system saves extra bowl

Problem: An integrator was looking for a new parts feeding system for their robot assembly of bearings. The client had two different bearing parts. One was fully round and the other was a half-round bearing. Both of these bearings were seated in a chamfered retainer...

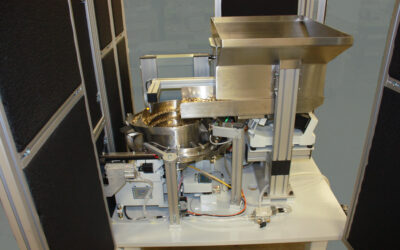

Vision system handles three different parts

Problem: The manufacturer of door hardware was in need of a way to automate the orientation and feeding of three different brass lock components for an assembly cell. The parts all shared the same two-lobe shape with one lobe having a hole and one being solid. Two of...

Optional three-lift parts feeder with no changeover

Problem: A manufacturer of hand-held outdoor equipment was in need of an automated parts feeding system that would lift bushing collars to three transfer stations on their assembly line. The three stations needed to operate independently of the other lines and supply...

Parts feeder rotates part in tight space for robotic pickup

Problem: An integrator was building an automated assembly system for a manufacturing customer. They needed a parts feeder for a heavy metal fastener that was picked up by a robotic arm and assembled. There were two issues of concern. First, the part had to be...

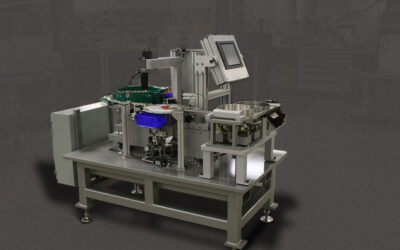

Plastic caps are closed, sealed and inspected at high speeds

Problem: A packaging manufacturer for disinfectant wipes needed to develop a new feeder system to handle their double seal lids. Demand for the product made it necessary to build a new line. The plastic lids were required to be fed at a high rate to the customer’s...

End-of-line mechanism feeds robot in limited space, saves labor costs

Problem: A manufacturer of auto engine components was having trouble finding enough qualified laborers to assemble their solenoid housing units. They wished to automate the pre-welding assembly of two parts. These had previously been hand assembled before being picked...

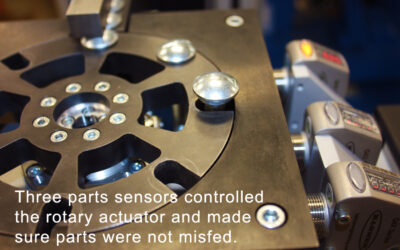

High tech rotary actuator orients and eliminates parts for truck axle assembly

Problem: The customer was an integrator working for a manufacturer of heavy truck axles. They needed a parts feeder system for their assembly automation that would be able to handle three different axle studs. Each was of a different length. Each of the studs had a...

Find a representative

In an Area Near You

We provide sales support across the United States. Find the Representative that services your area.