Feeder Bowls Case Studies

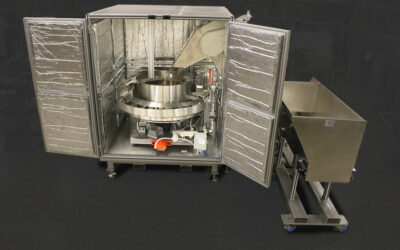

No-spark C1D1 FDA parts feeding

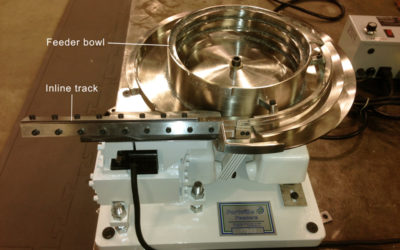

Problem: A manufacturer of syringe filling machines needed a complex parts feeding system. They were designing a system for operations in a C1D1 manufacturing environment where highly flammable and explosive material was being used. That required no electrical wiring...

FDA parts feeder system fits in tight spaces

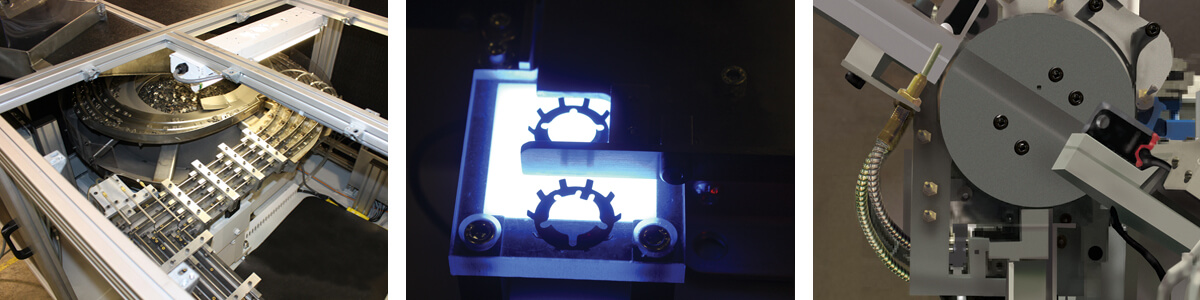

Problem: An integrator was building an assembly system that handled 64 different flat rubber seals. There were very tight quarters for the machinery, especially the feeder system. The space was so tight that the standard-sized feeder equipment would have to be sized...

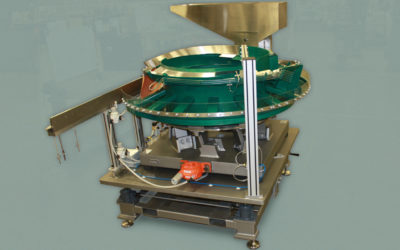

Spring feeder detangles bulk parts and delivers at high speeds

Problem: A manufacturer of metal components produces a conical spring and needed a feeder system that would handle bulk springs and deliver them at 140 parts per minute to their assembly station. The problem was the springs were easily tangled in bulk situations. The...

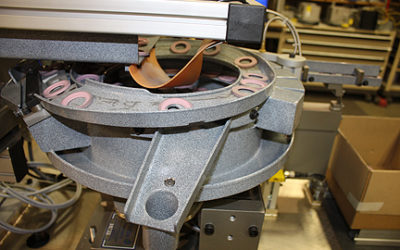

Two parts feeders synced for assembly automation

Problem: An integrator was building an assembly and labeling automation system for a medical packaging company. The high-speed system labeled vials and capped them before being filled. The customer needed two feeder systems; one for the vials and one for the caps,...

Medical Grade Feeder Systems help meet the need of clinical product shortages

Problem: A medical packaging integrator was in need of bulk feeder systems for their vial assembly operations. They had a contract with a worldwide leader in biotechnical and pharmaceutical testing to integrate eight new parts feeder systems into their existing...

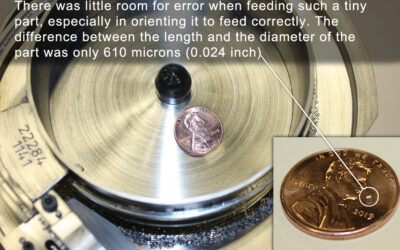

Ultra tiny parts feeder for iridium metal electrodes

Problem: Fortville Feeders will service any feeder system, regardless of its manufacturer. On one such service call to the manufacturer of spark plugs, the customer was having trouble getting a very small iridium electrode to feed correctly. The electrodes were...

Cap feeder for combustible products

Problem: The customer was bottling highly combustible consumer products in aerosol cans. They needed an automated feeder system to handle five different caps for these cans. The feeder had to orient and move the parts at a high speed, but more importantly, it had to...

Five-line, high-speed parts feeding system

Problem: The manufacturer of water treatment control valves was looking for a way to automate their parts feeding and loading system that would continuously feed five conveyors that supplied their assembly station. The loading had previously been done by hand. The...

Surlyn coated feeding system prevents parts from being damaged

Problem: The customer was in need of a feeder system for delicate ceramic parts. The system had to move the parts without scratching or damaging them. Solution: Fortville designed a bulk hopper and vibratory feed system all overlaid with a Surlyn coating. A...

Feeder systems for very small parts

Problem: The customer needed to sort and orient small wire parts (.150″ squares made with .0085″ wire) for high speed automation. They needed a system that would feed and track the parts reliably. Solution: With any small part, positioning in correct...

Find a representative

In an Area Near You

We provide sales support across the United States. Find the Representative that services your area.