Tracking Systems Case Studies

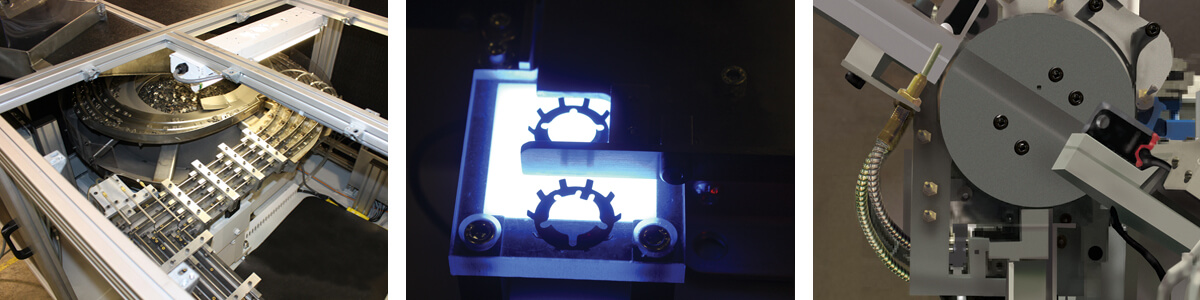

Four-part feeder supplies assembly cell in tight spaces

Problem: The manufacturer of auto parts was looking for a new parts feeder solution for an assembly cell. Their engineers had designed the assembly cell with a dead nest to handle four parts, which were assembled and placed on a conveyor. This required the parts to be...

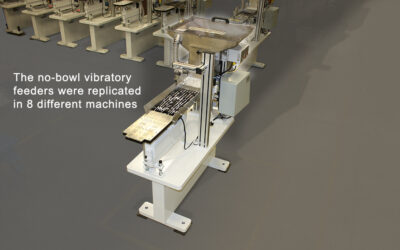

No-bowl vibratory parts feeding system delivers at high speeds

Problem: An integrator needed eight parts-feeding systems that would feed oblong plastic parts at high speeds. The only difference in the machines were the number of lines needed to feed the assembly line. They asked for a traditional vibratory feeder bowl system that...

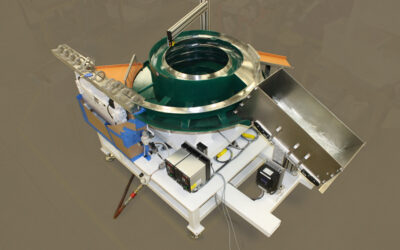

Two-for-one parts feeder system saves extra bowl

Problem: An integrator was looking for a new parts feeding system for their robot assembly of bearings. The client had two different bearing parts. One was fully round and the other was a half-round bearing. Both of these bearings were seated in a chamfered retainer...

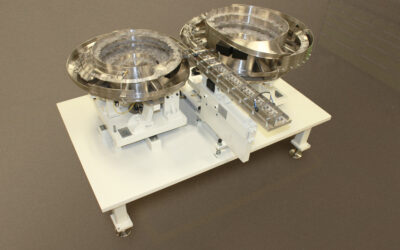

Two bowls with one inline track saves space

Problem: A medical device manufacturer needed to replace an inefficient feeder system for two caps. The system they had attempted to feed two parts from the same vibratory bowl. The two caps had very different geometries. It caused constant jams in their old feeder....

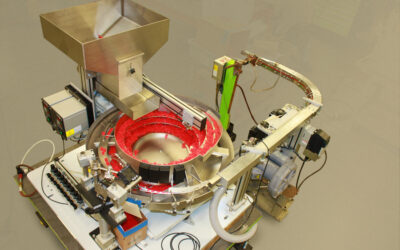

High-speed plastic parts feeder with anti-clog conveyor

Problem: The manufacturer of plastic containers was in need of an automated feeder system for their closure components. They needed a high-speed system that would handle the molded plastic parts without clogging the machine while supplying their assembly lines at 200...

Three identical medical part feeders with one variance

Problem: An automated machine builder that specialized in medical syringe assembly and packaging was in need of three identical feeder machines to handle needle holders. The parts were lightweight, very small (1 mm and 3mm widths) and needed to be fed at a rate of 54...

Bulk Feeding Glass Vials

Problem: An integrator was building an automated system that packaged five different sizes of medical glass pipettes. The pipettes were very fragile and had to be gently handled, but delivered at 80 parts per minute. This included bulk loading of the parts, moving...

Retrofit Cap Feeder adds an additional line to existing machine

Problem: A medical liquids bottler had a capping machine that used a Fortville Feeders designed parts feeder. The bottler made some changes to their bottling automation and needed a system that fed two lines instead of one. They approached Fortville Feeders to...

Multi-part feeder system delivers five pump nozzle caps with one machine

Problem: The manufacturer of hand sanitizer bottles desired a single feeder system for multiple foaming pump nozzles for their automated bottling assembly station. They had five different pump nozzles that were of different sizes and geometries. Some of these pump...

Two parts feeders synced for assembly automation

Problem: An integrator was building an assembly and labeling automation system for a medical packaging company. The high-speed system labeled vials and capped them before being filled. The customer needed two feeder systems; one for the vials and one for the caps,...

Find a representative

In an Area Near You

We provide sales support across the United States. Find the Representative that services your area.