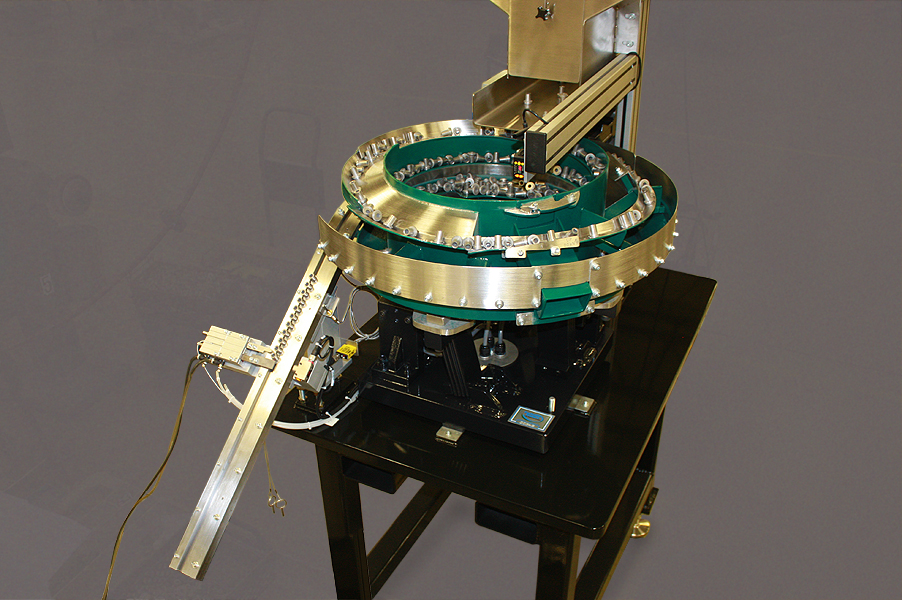

Problem: An integrator was building a parts resonance testing machine that checked powdered metal parts for defects. Powdered or sintered metal is prone to inclusions – cracks or pockets where air is trapped which weakens the structural integrity of the part. Resonance frequency testing uses high-sensitivity microphones to quantify the sound of parts as they hit a metal drum. Imperfections are detected by comparing the frequency spectrum and amplitude of the test part to a known good part.

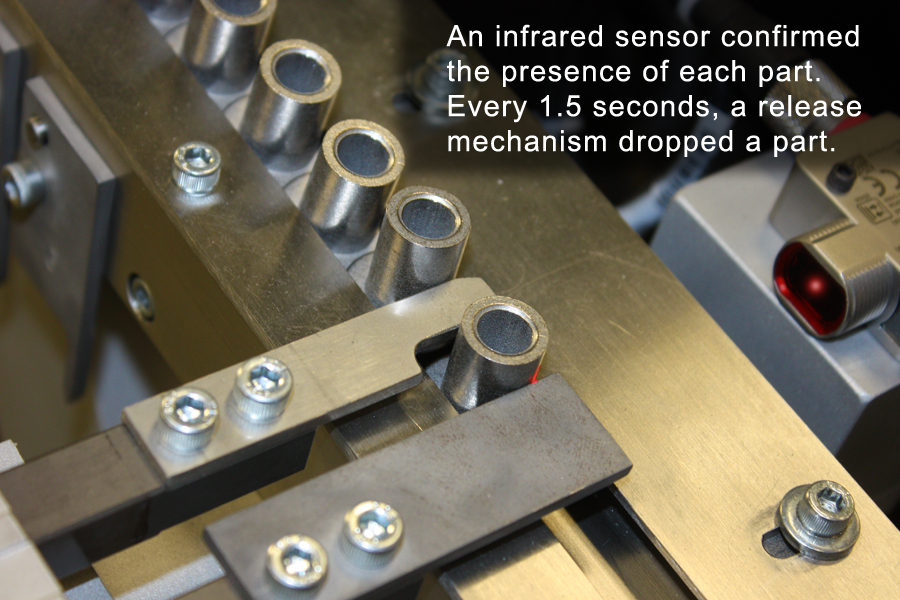

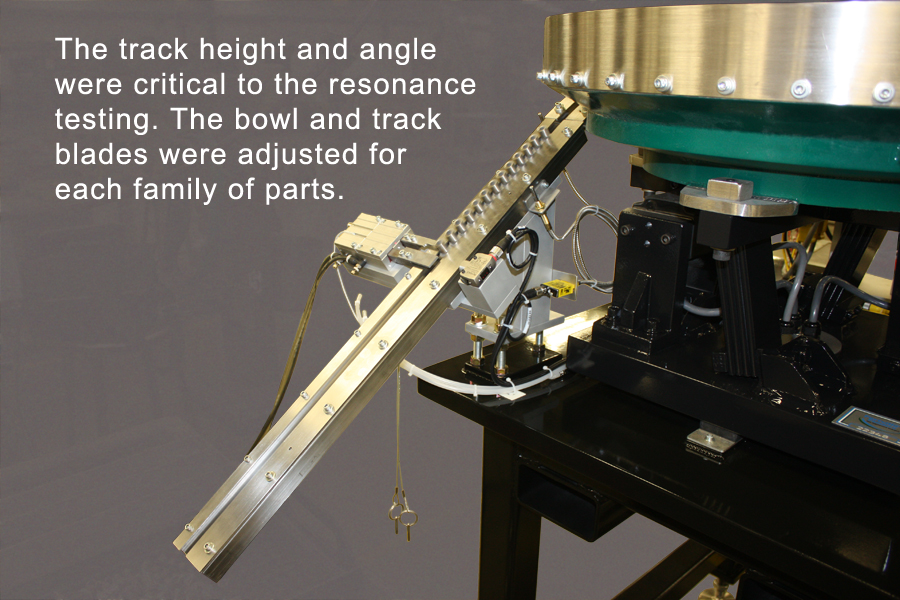

Solution: Resonance inspection requires that parts be dropped at a specific direction, speed, and frequency to be properly evaluated. Fortville Feeders’ engineers met with the customer to determine the best way to drop the parts into the drum. They designed a gravity track with a release mechanism that discharged one part every 1.5 seconds. Fortville tested the height and angle needed to drop the part at the specified speed.

However, to make things more complex, the customer wanted the feeding system to handle seven different parts. Each of them had their own unique shape and weight. The system would have to adjust to orient them and drop them at exactly the same height. To accommodate all of these parts, Fortville designed three adjustable track segments. The track was converted for each family of part. Typically parts changeover can take a lot of time with possible fine adjustments taking longer. In this case Fortville’s expertise in building highly technical and adaptable parts feeder systems was demonstrated by the quick changeover track they designed for each family of part. The changeover happened by the use of pins to positively locate each segment. Each changeover was accomplished in less than two minutes. When not in use, the pins were hung from the side of the track for easy access.

When completed, the feeder system for the resonance tester was just what the customer needed. Fortville’s attention to detail in a highly technical application proved to be successful.

Recent Comments