by Fortville Feeders | Jul 22, 2024 | Uncategorized

Problem: A medical parts manufacturer needed a parts feeder for the packaging of very small staples. Since this was a medical staple, the feeder system needed to meet cleanroom compliance standards. The part could not be handled during the feeding process and must be...

by Fortville Feeders | Sep 1, 2023 | Featured, Feeder Bowls

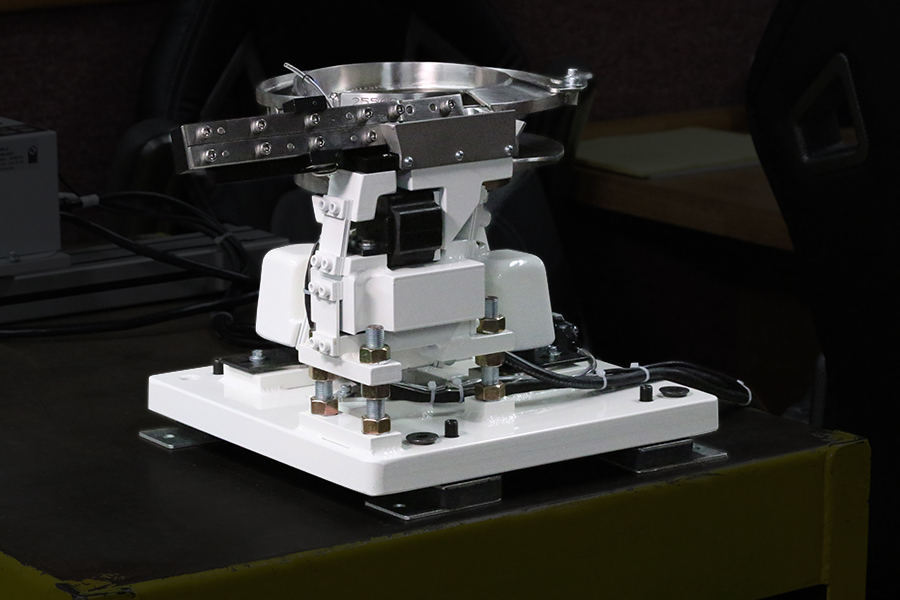

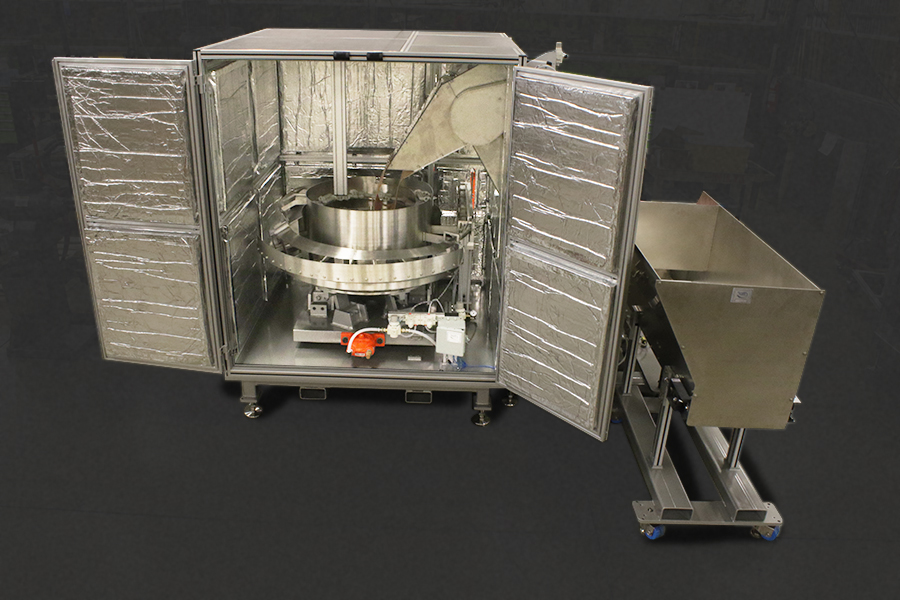

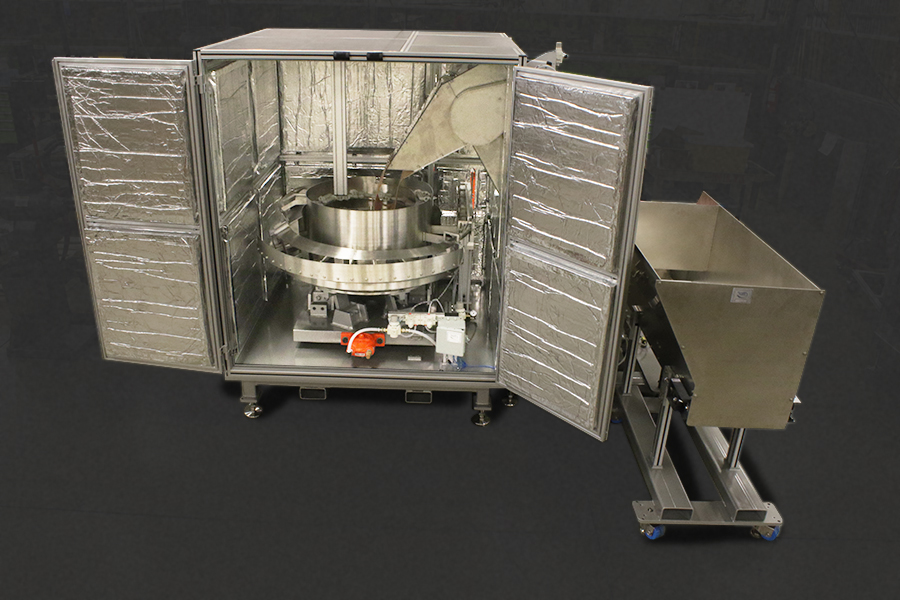

Problem: A manufacturer of syringe filling machines needed a complex parts feeding system. They were designing a system for operations in a C1D1 manufacturing environment where highly flammable and explosive material was being used. That required no electrical wiring...

by Fortville Feeders | May 17, 2021 | Featured, Tracking Systems

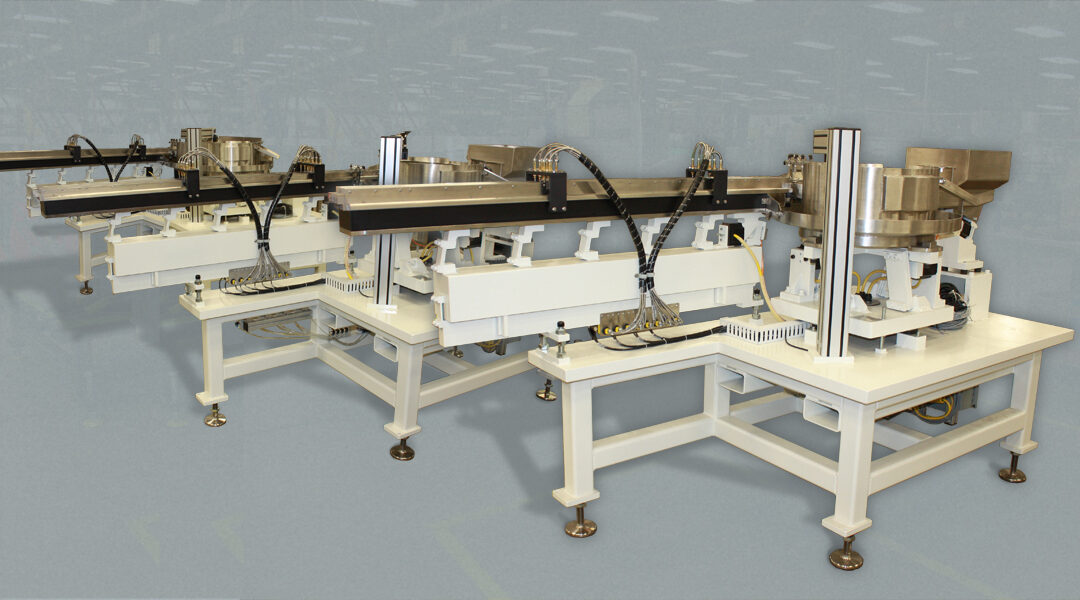

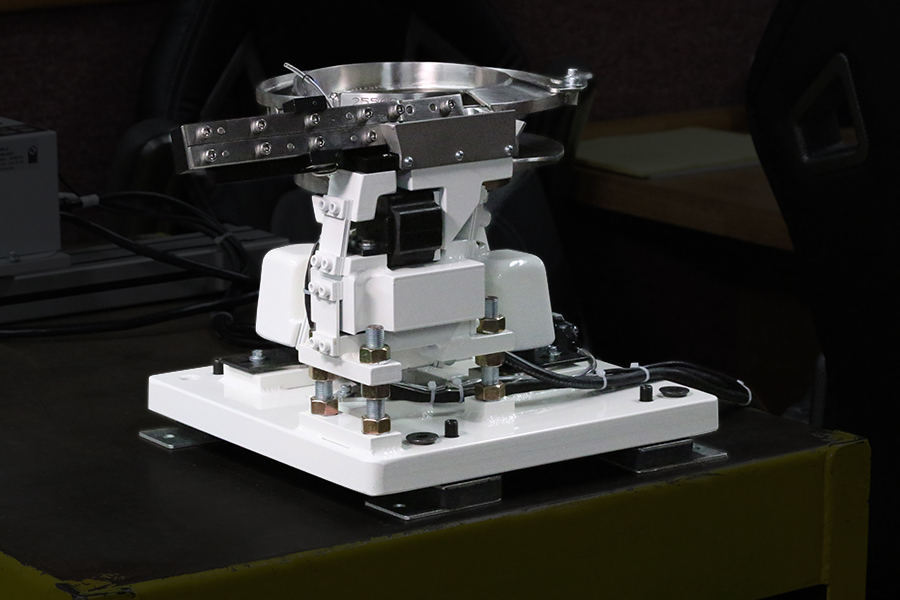

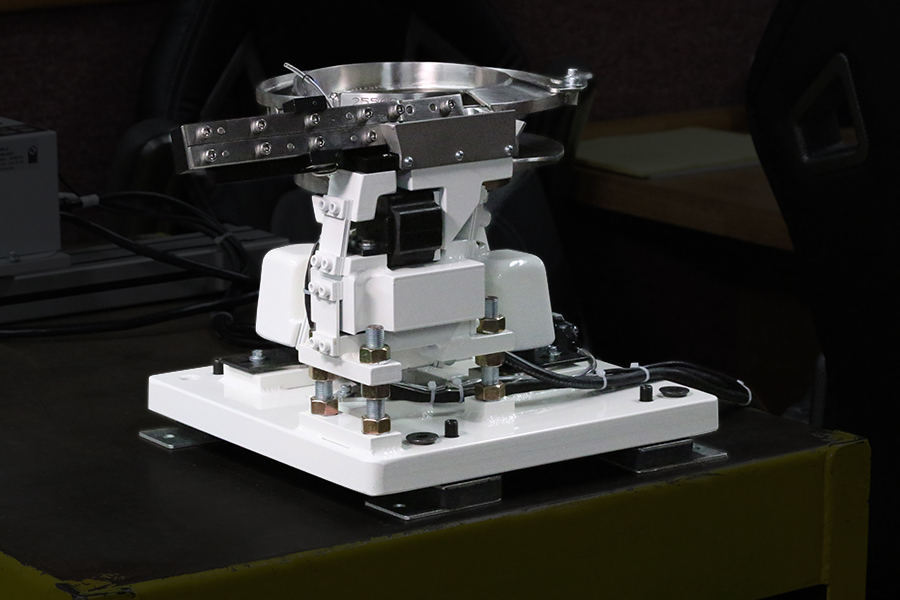

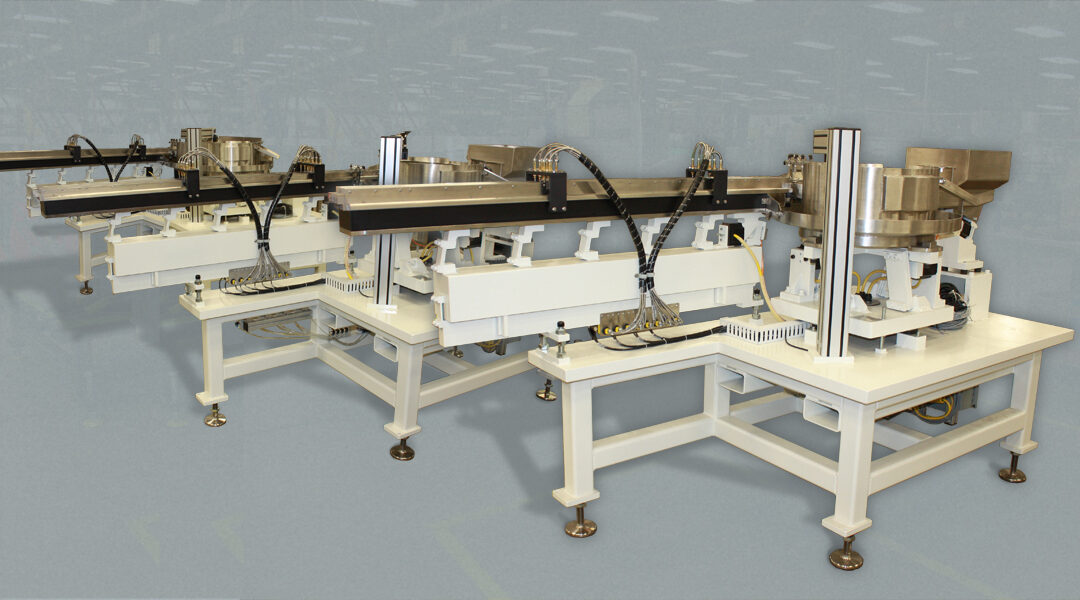

Problem: An automated machine builder that specialized in medical syringe assembly and packaging was in need of three identical feeder machines to handle needle holders. The parts were lightweight, very small (1 mm and 3mm widths) and needed to be fed at a rate of 54...

by Kevin Yaney | Mar 25, 2021 | Featured, Tracking Systems

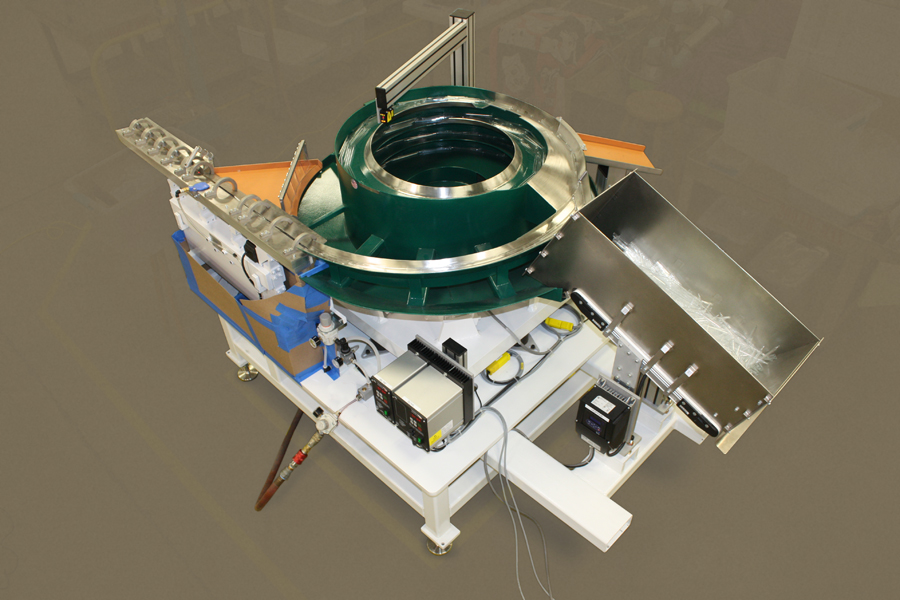

Problem: An integrator was building an automated system that packaged five different sizes of medical glass pipettes. The pipettes were very fragile and had to be gently handled, but delivered at 80 parts per minute. This included bulk loading of the parts, moving...

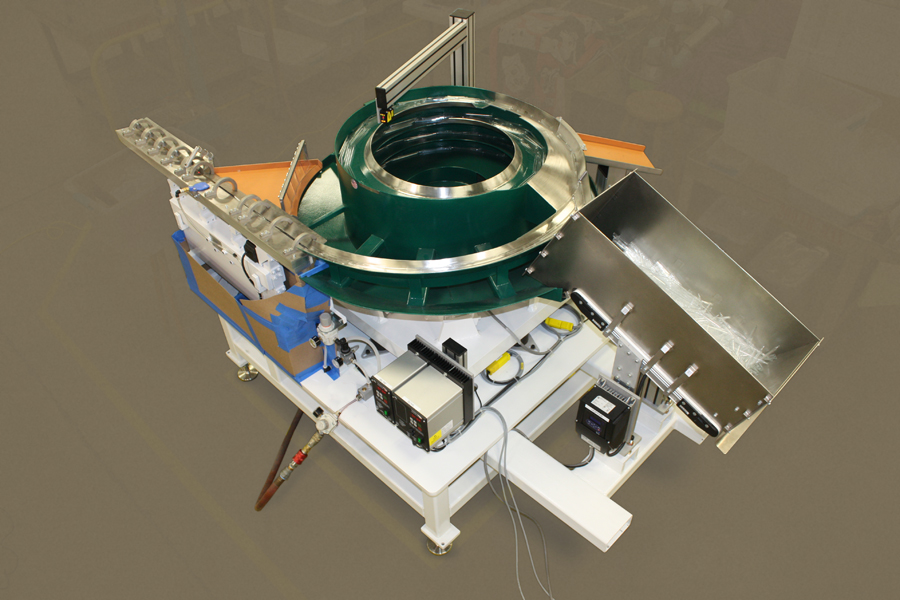

by Fortville Feeders | Apr 9, 2020 | Featured, Feeder Bowls

Problem: A medical packaging integrator was in need of bulk feeder systems for their vial assembly operations. They had a contract with a worldwide leader in biotechnical and pharmaceutical testing to integrate eight new parts feeder systems into their existing...

Recent Comments