Problem: International Engineering is a producer of snowmobile performance and safety traction products. They had been operating an aging automated parts feeder system that took an extensive amount of time to changeover from one part to another. IE had 13 different parts that were fed into the system. It also was becoming costly to maintain. They were looking for a feeder system that would eliminate the downtime in both changing out parts and servicing the system.

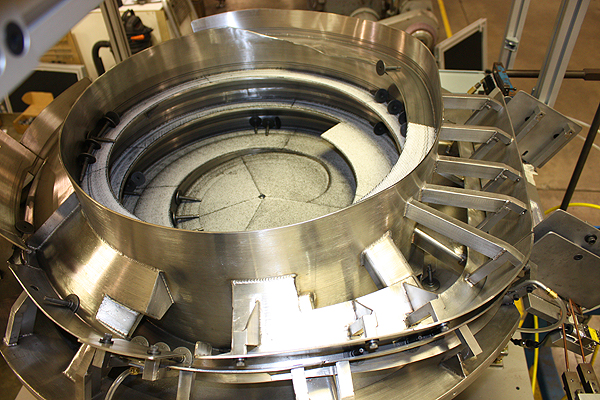

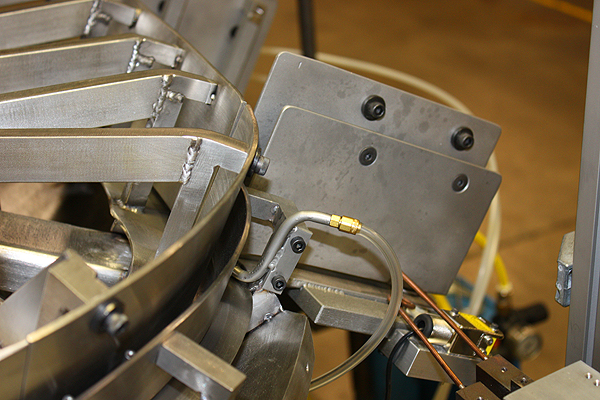

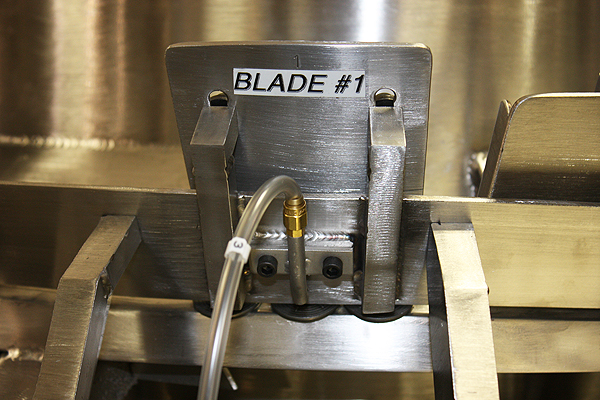

Solution: Fortville designed a dual discharge feeding system to accommodate all 13 different parts. This included making allowances for height and width differences in the varying styles of parts, plus orienting each part that was fed onto the customer’s tracks. The key to making this work was a quick changeover. To change from one part to the next, the system included a single step for the operator, and this took a mere 10 seconds for the changeover.

Recent Comments