by Fortville Feeders | Jun 27, 2019 | Feeder Bowls

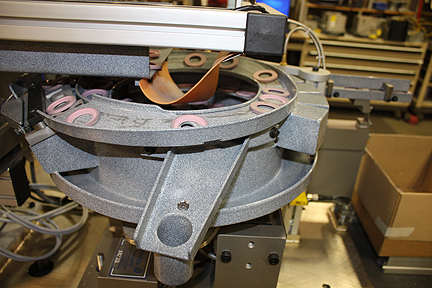

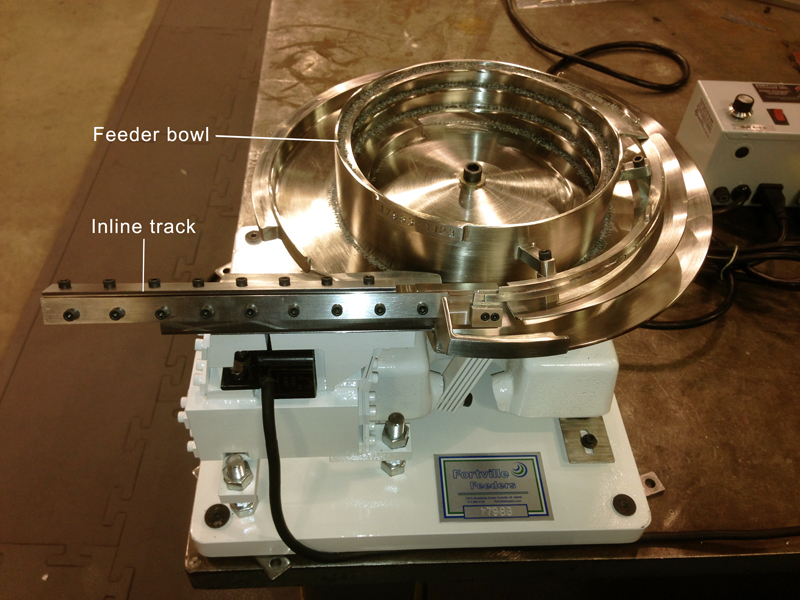

Problem: The customer was in need of a feeder system for delicate ceramic parts. The system had to move the parts without scratching or damaging them. Solution: Fortville designed a bulk hopper and vibratory feed system all overlaid with a Surlyn coating. A...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls, Tracking Systems

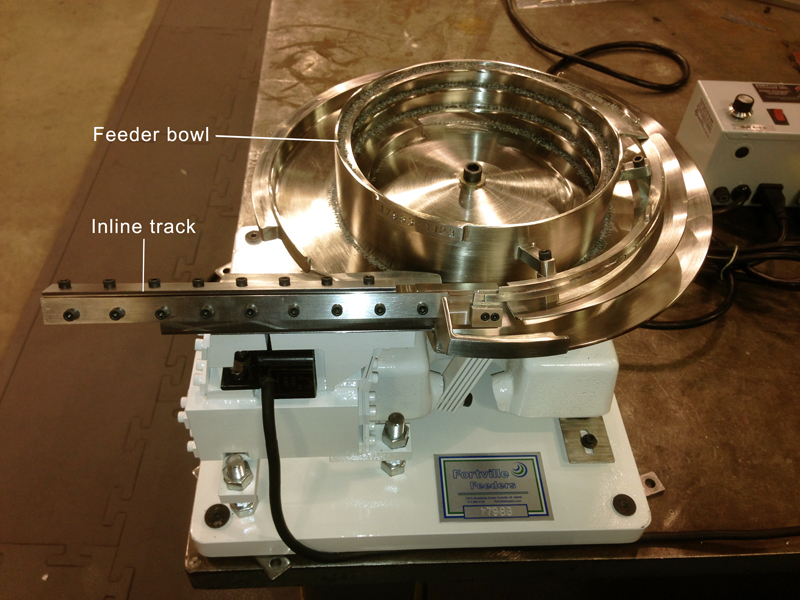

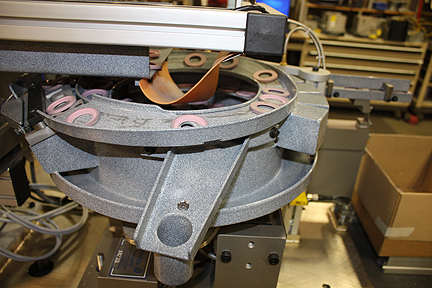

Problem: The customer needed to sort and orient small wire parts (.150″ squares made with .0085″ wire) for high speed automation. They needed a system that would feed and track the parts reliably. Solution: With any small part, positioning in correct...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls, Tracking Systems

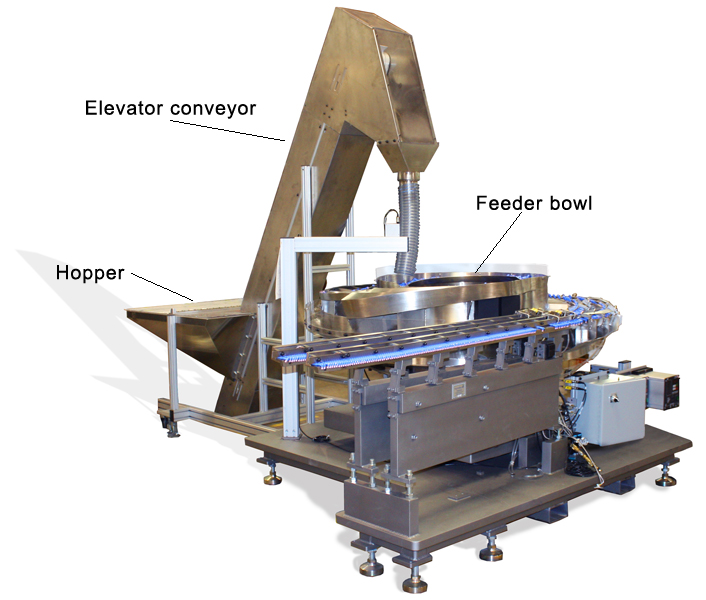

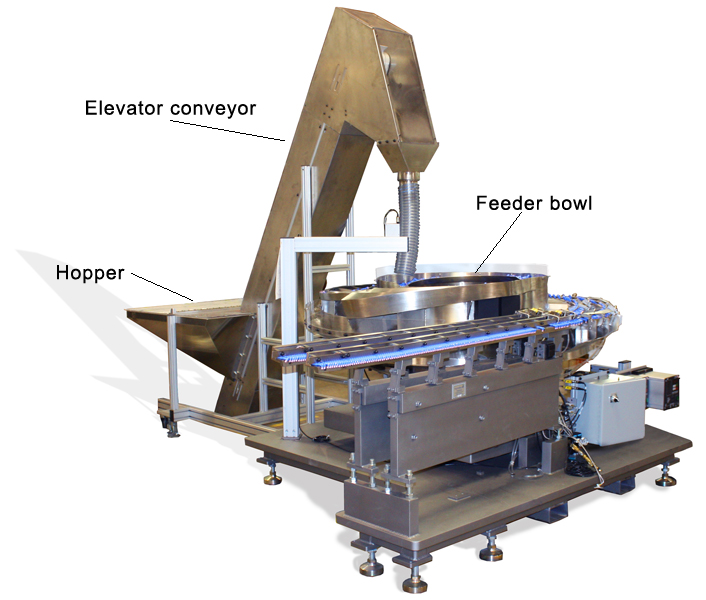

Problem: The customer was packaging prophy angles that are used in dentists offices for teeth cleaning. They wanted a feeder system that would run a dual line for their bagging systems. Each line would be required to feed up to 200 parts per minute....

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls, Tracking Systems

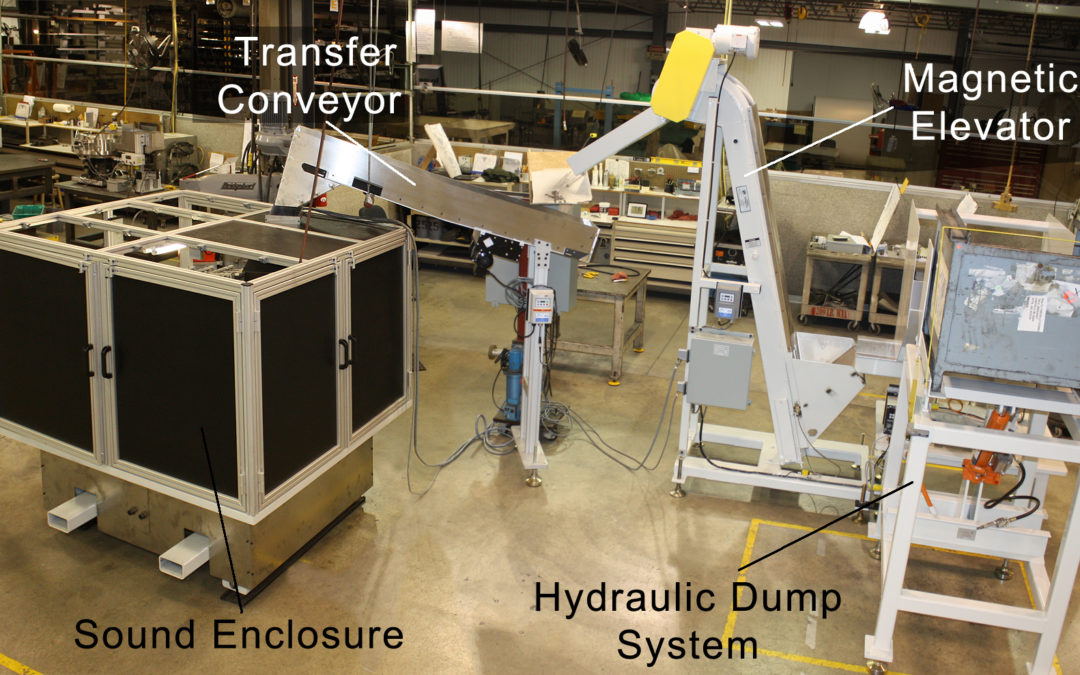

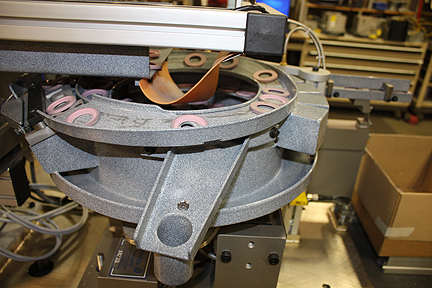

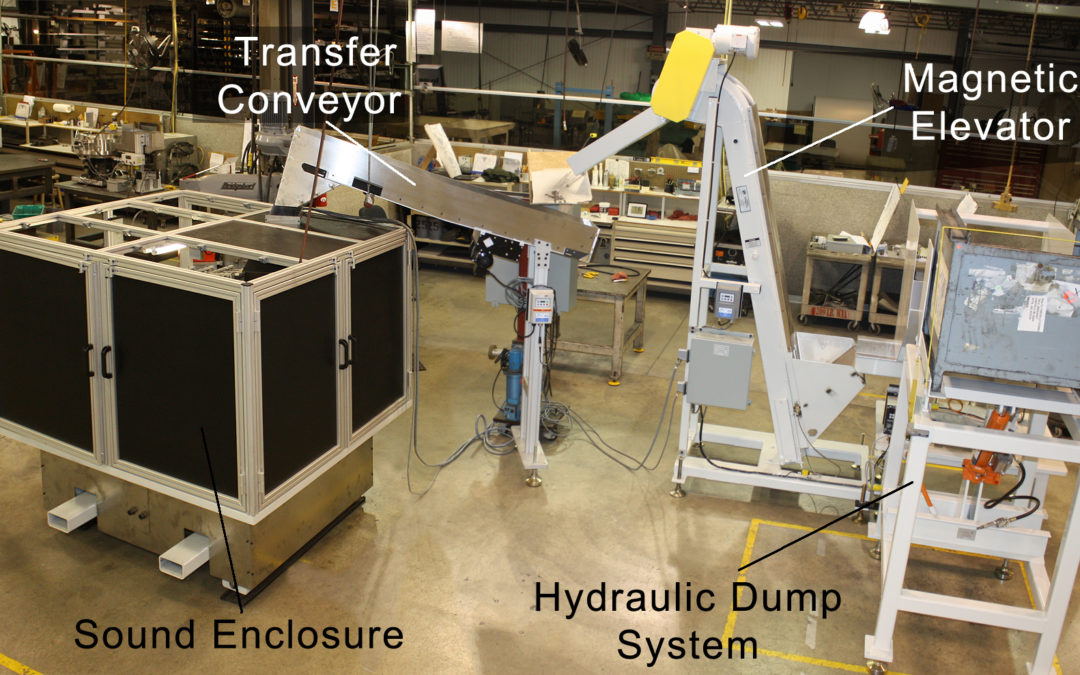

Problem: The customer had a need to feed a four line grinding machine with a continuous feed of parts. They had a bulk parts tote for their parts and a washing system, but needed to automate the loading and sorting process from start to finish....

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls, Tracking Systems

Problem: The customer needed to sort and move bulk plastic caps to two robots for pickup. The parts needed to be moved over 50 feet. However, there was a problem with space. The shop floor needed to be kept clear for rolling equipment and the existing machinery....

Recent Comments