Escapements and Mechanisms Case Studies

10 bowl push mechanism feeds robotic assembly on demand

Problem: A manufacturer needed a feed system to supply 10 spacers of various thicknesses to be used in the assembly of mechanical components. The spacers were picked and placed by robots that could be programmed to select any of the 10 spacers needed for the assembly....

Testing equipment leads to a better feeder system for rubber valve components

A manufacturer of valves needed an automated part feeding solution for a rubber insert that was a component of the product assembly. Fortville Feeders designed a vibratory inline feeder that fed a rotary actuator. The wheel handed parts off to the customer’s pick and...

Small pins with few distinguishing features are fed without misfeeds

Problem: The manufacturer of critical control products was looking for a way to feed bulk pins to an assembly robot. The pins were small and, other than large and small openings at opposite ends, had no other distinguishing features. It was critical that the pins be...

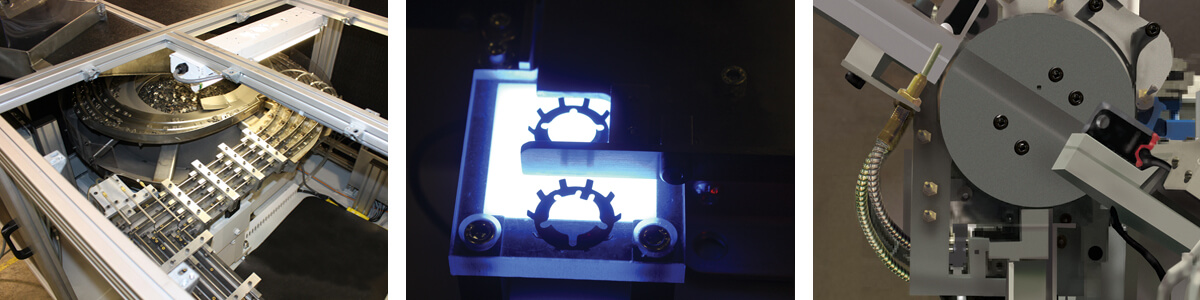

Three step mechanism assembles and feeds magneto parts to robotic assembly

Problem: A lawnmower manufacturer needed to update a parts feeder on their assembly line. The equipment fed two components of a magneto to a robot. The two parts needed to be assembled, with a magnet placed inside a plastic holder before the robot picked it up....

Feeder system handles oily parts, positions for robotic pick up

Problem: The customer needed to have a flux sleeve steel part oriented and isolated for robotic arm pick up. The problem: the parts were required to be drenched in oil prior to pick up. Oily parts are not only messy, they have a tendency to stick together or...

Feeder system with X-Y table loads tiny parts into matrix tray

Problem: The customer was hand loading very small pins into a tray, with a matrix of pockets, for robotic pick up. Each tray held 1,380 pins. This was a tedious and time consuming process. The customer was seeking an automation solution to present the pins for...

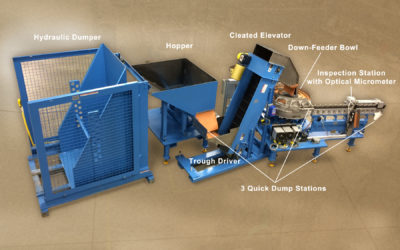

Quick changeover vibratory feeder system handles 8 different bolts

Problem The customer needed a way to feed large bolts of varying lengths to its heavy duty wheel hub assembly cell. They manufacture eight different axle assemblies, each with a different size wheel bolt. They needed a feeder system that could handle all eight...

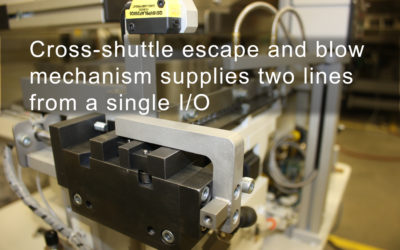

Compound movement mechanism blow feeding shingled bolts

Problem The customer is a manufacturer of small gasoline engines used in lawn and garden implements. They had a feeder system that moved very small bolts to two staging locations. The system used a single feeder bowl and an escape and blow device with a diverter that...

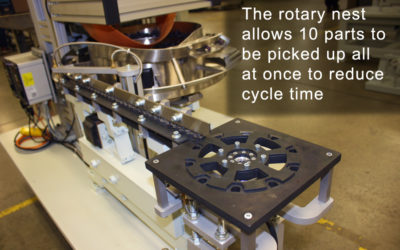

Rotary indexer nest allows 10 parts to be picked at once

Problem: The customer was building a robotic assembly solution for an auto manufacturer. The procedure required 10 bolts to be picked up and turned in place by the robot. This had previously been performed one bolt at a time. The customer had developed a...

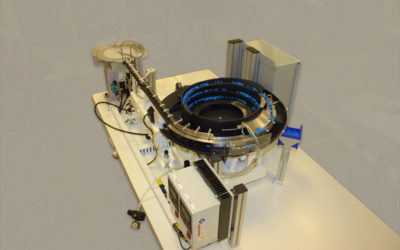

Dual index wheels position small parts for robotic pick up

Problem: The customer was upgrading the automation machinery for the manufacturer of gas flow meters. Two components of the meter were different sized pointers assembled on the face of the gauges. There were three challenges with this feeder system. First, these...

Find a representative

In an Area Near You

We provide sales support across the United States. Find the Representative that services your area.