Escapements and Mechanisms Case Studies

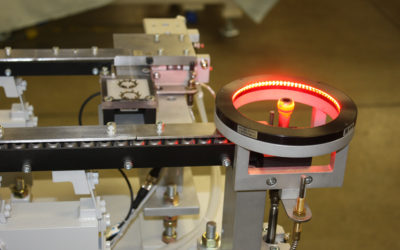

High speed rivet assembly feeder uses programmable rotary indexers

Problem: An integrator was building a robot assembly for an automotive manufacturer. The robots fastened rivets at a rate of 180 ppm. There were two configurations for the rivets to fit into metal plates. One configuration required 15 rivets per cycle and the...

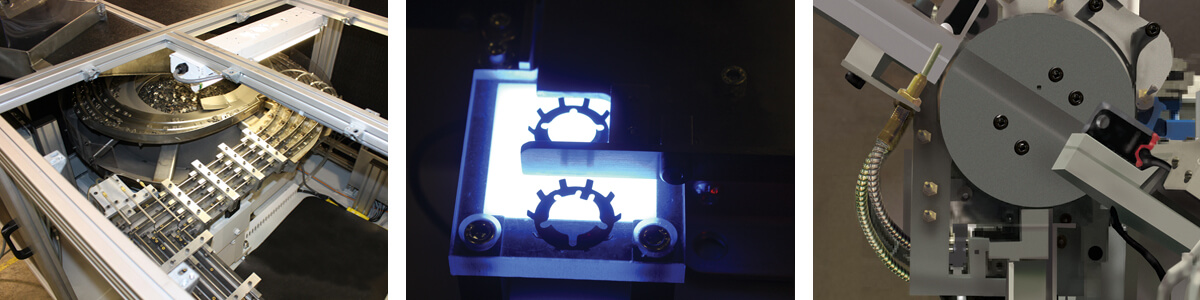

Four parts run on same feeder system without changeover

Problem: An integrator was building a robotic assembly station that handled four different stamped aluminum parts. The parts all had a double-ear geometry that needed to be presented to the robot ears leading. However each of the four parts had a unique shape....

Escapements and mechanisms case studies

Our engineered solutions are evident with the precise hand off of parts in our end-of-line mechanisms and escapements. Take a look at real-life case studies of solutions to parts feeding problems.

In-Line cleaning mechanism saves parts from being scrapped

Problem: A manufacturer of tubular assemblies and precision machined products for the auto industry. They had a problem with extraneous materials, such as chips and shavings, getting into the ID of the machined parts as they...

Three-part lift mechanisms feed robotic arm

Problem: The customer had three parts that needed to be fed to a robot for pick up and assembly. The parts needed to be isolated and lifted to a location where a robotic arm would grip the part at a high rate. They were looking for a feeder system that met their...

Infrared scanner integrates with lift mechanism and robotic arm

Problem: A manufacturer of home appliances wanted to automate the assembly of its kitchen mixers. Previously all hand assembled, they had contacted a robotics builder to help them automate the process. Two particular parts were a challenge. A star washer with...

Find a representative

In an Area Near You

We provide sales support across the United States. Find the Representative that services your area.