Feeder Bowls Case Studies

High speed, dual-line feeder system for dental equipment

Problem: The customer was packaging prophy angles that are used in dentists offices for teeth cleaning. They wanted a feeder system that would run a dual line for their bagging systems. Each line would be required to feed up to 200 parts per minute....

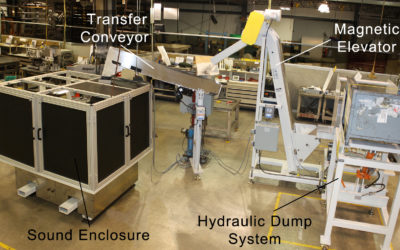

Customized loading and sorting of parts for a four line grinder

Problem: The customer had a need to feed a four line grinding machine with a continuous feed of parts. They had a bulk parts tote for their parts and a washing system, but needed to automate the loading and sorting process from start to finish....

Sorting and conveyor system moves parts 14 feet above the floor

Problem: The customer needed to sort and move bulk plastic caps to two robots for pickup. The parts needed to be moved over 50 feet. However, there was a problem with space. The shop floor needed to be kept clear for rolling equipment and the existing machinery....

Automating loading processes and eliminating damaged parts

Problems: The customer produces machined parts for the automotive industry. They were using a hand-loaded gravity track for grinding operations. This led to inconsistency in the way parts were loaded, which caused stops and starts to the process. Also,...

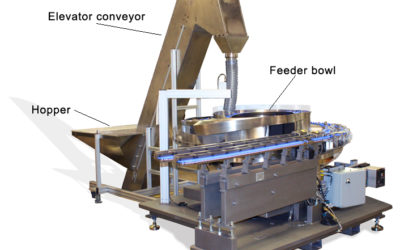

FDA approved feeder bowl system

Problem: The customer needed a feeder bowl system that met FDA specifications for materials that would come in contact with parts used in drug packaging. The customer had requested that their system be constructed with an electropolished stainless steel wherever...

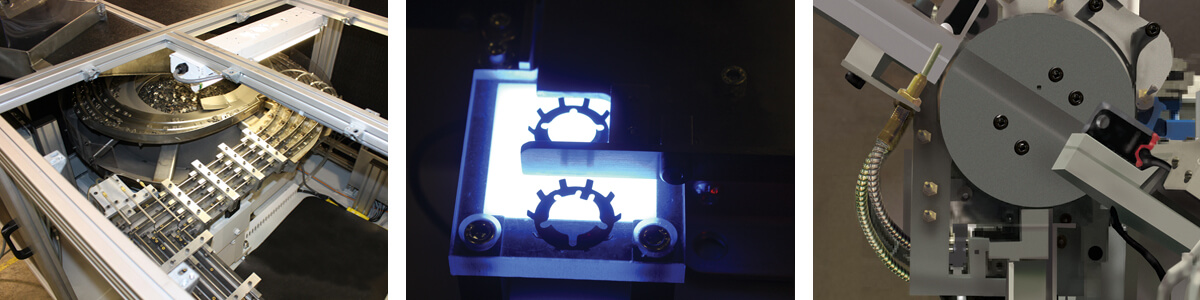

Dual feeder bowls send two parts to one dead nest system

Problem: This customer needed to have an efficient way to feed two parts – a bushing and an insert – to a common dead nest for pick- up with their robot. Solution: Fortville built a dual vibratory feeder bowl system that fully automated the loading of parts...

Feeder system for small coil springs

Problem: The customer works with small, coiled metal springs. Moving them from bulk to a singular spring for their automated machinery proved to be a challenge. Springs have a tendency to tangle and clog machinery. Operators had to constantly monitor the supply...

Three part feeder system for a multi-tooled gripper

Problem: The customer wanted to redesign a three part feeder system. The three parts would be picked up and assembled by a robotic gripper arm. It was important that the new feeder system save space, be able to work with their robot, and be able to match...

Four line feeder system retrofit to orient new part with quick changeover

Problem: The customer grinds valve springs for the automotive industry. Two problems were solved with a new vibratory feeder bowl system. Initially, Suncall America contacted Fortville to help them improve efficiencies. They wanted to build a system that would...

Air driven track with PLC changeover for three parts

Problem: The customer produces refrigerant recharging cans. They had three different types of auto discharge valves that are assembled as caps on to their cans. They also had different can sizes. They needed a feeder system that could be set up for any of the...

Find a representative

In an Area Near You

We provide sales support across the United States. Find the Representative that services your area.