Tracking Systems Case Studies

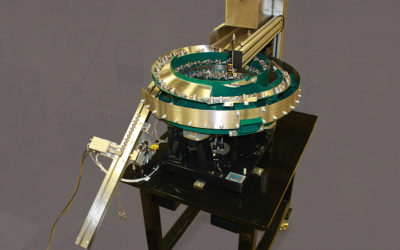

10 bowl push mechanism feeds robotic assembly on demand

Problem: A manufacturer needed a feed system to supply 10 spacers of various thicknesses to be used in the assembly of mechanical components. The spacers were picked and placed by robots that could be programmed to select any of the 10 spacers needed for the assembly....

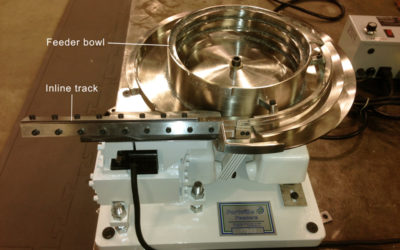

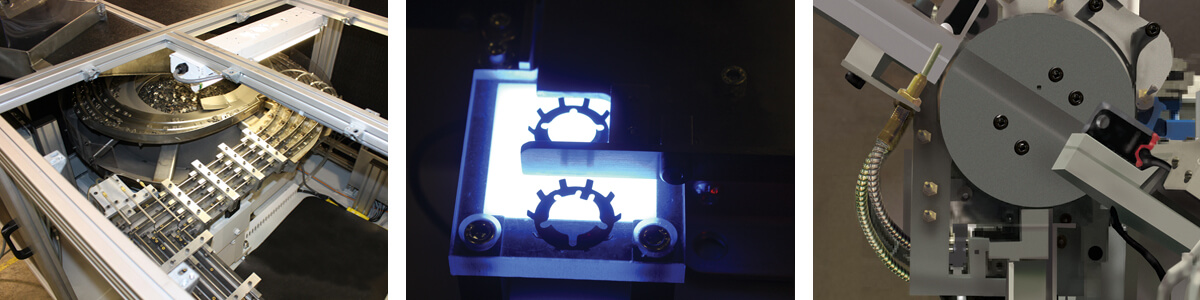

Feeder system resonates with testing equipment manufacturer

Problem: An integrator was building a parts resonance testing machine that checked powdered metal parts for defects. Powdered or sintered metal is prone to inclusions – cracks or pockets where air is trapped which weakens the structural integrity of the part....

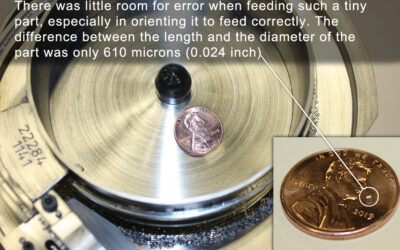

Ultra tiny parts feeder for iridium metal electrodes

Problem: Fortville Feeders will service any feeder system, regardless of its manufacturer. On one such service call to the manufacturer of spark plugs, the customer was having trouble getting a very small iridium electrode to feed correctly. The electrodes were...

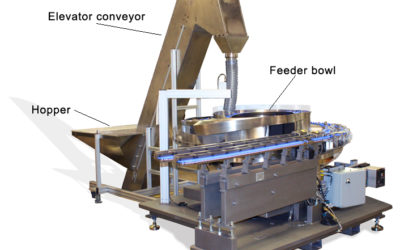

Five-line, high-speed parts feeding system

Problem: The manufacturer of water treatment control valves was looking for a way to automate their parts feeding and loading system that would continuously feed five conveyors that supplied their assembly station. The loading had previously been done by hand. The...

High-speed, lightweight parts feeding system

Problem: A manufacturer of ear protection devices needed two small parts – stems for earplugs - fed to their assembly equipment at a high rate of speed. The plastic stems had to be oriented properly, with the smaller diameter end leading. Any damaged or irregular...

Feeder systems for very small parts

Problem: The customer needed to sort and orient small wire parts (.150″ squares made with .0085″ wire) for high speed automation. They needed a system that would feed and track the parts reliably. Solution: With any small part, positioning in correct...

High speed, dual-line feeder system for dental equipment

Problem: The customer was packaging prophy angles that are used in dentists offices for teeth cleaning. They wanted a feeder system that would run a dual line for their bagging systems. Each line would be required to feed up to 200 parts per minute....

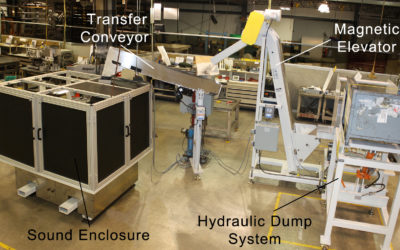

Customized loading and sorting of parts for a four line grinder

Problem: The customer had a need to feed a four line grinding machine with a continuous feed of parts. They had a bulk parts tote for their parts and a washing system, but needed to automate the loading and sorting process from start to finish....

Sorting and conveyor system moves parts 14 feet above the floor

Problem: The customer needed to sort and move bulk plastic caps to two robots for pickup. The parts needed to be moved over 50 feet. However, there was a problem with space. The shop floor needed to be kept clear for rolling equipment and the existing machinery....

Vibratory feeder bowl Brushlon lined to protect bulk parts

Problem: The customer needed a parts feeder system that would move bulk parts into position in the correct orientation for pickup. These parts were prone to be scratched or damaged in a normal bulk feeder. They needed an...

Find a representative

In an Area Near You

We provide sales support across the United States. Find the Representative that services your area.