by Fortville Feeders | Jun 26, 2019 | Escapements and Mechanisms, Feeder Bowls

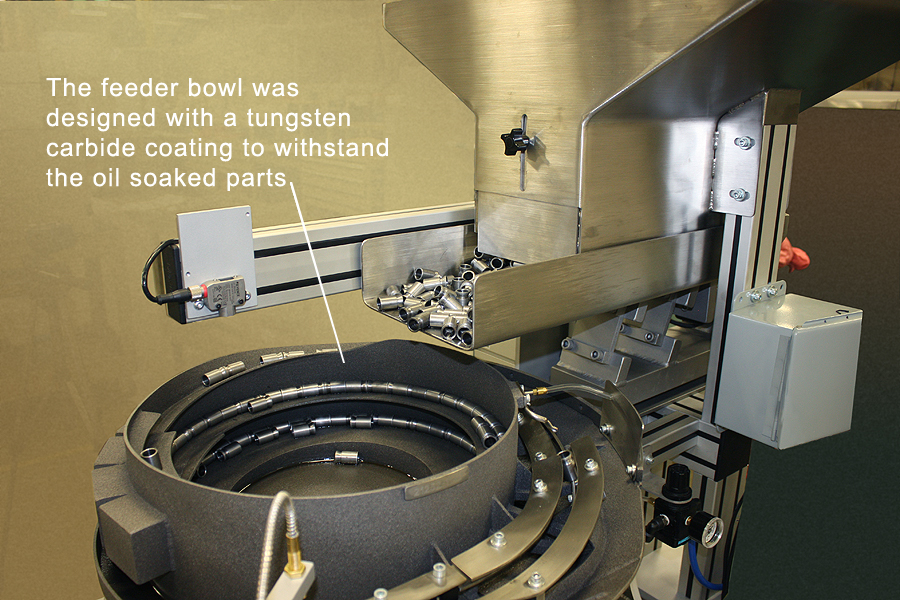

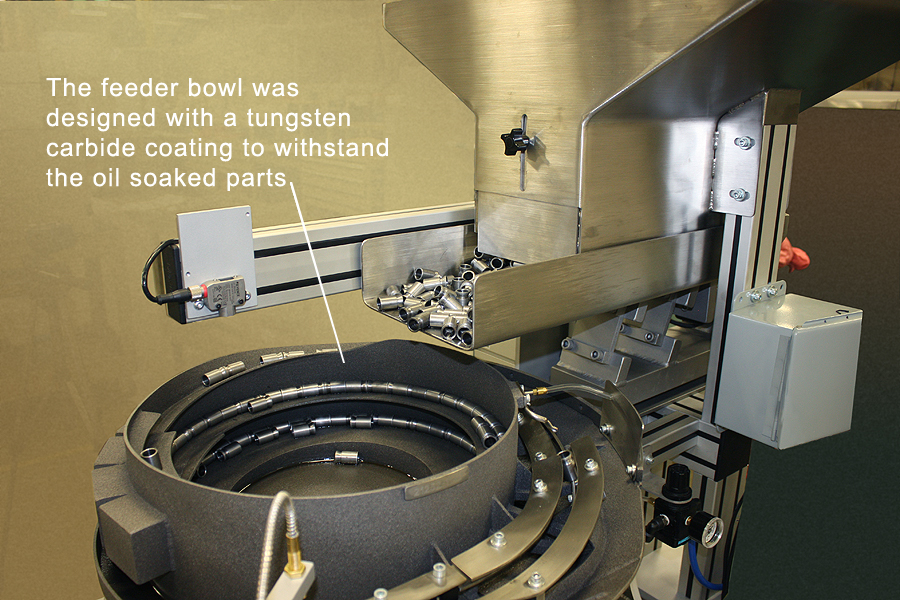

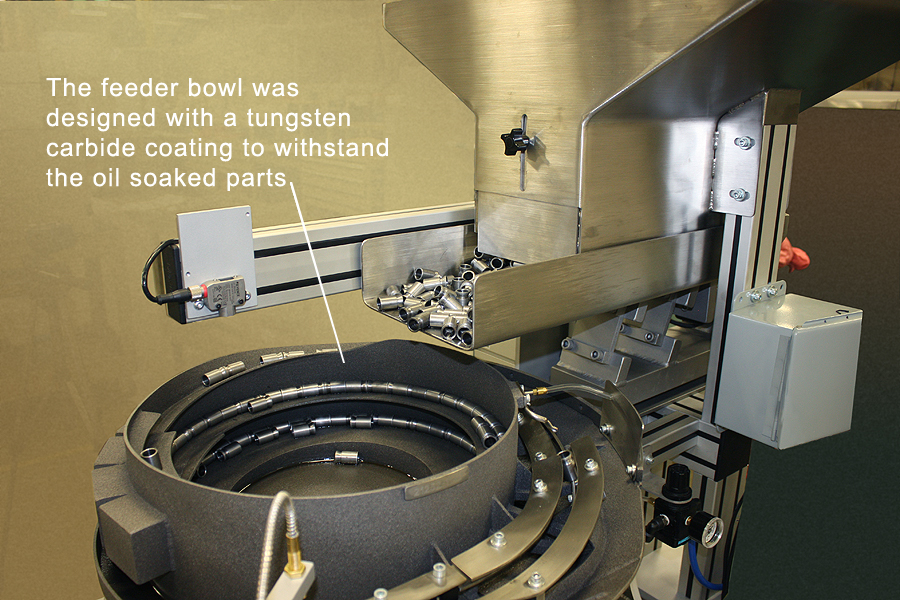

Problem: The customer needed to have a flux sleeve steel part oriented and isolated for robotic arm pick up. The problem: the parts were required to be drenched in oil prior to pick up. Oily parts are not only messy, they have a tendency to stick together or...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: A manufacturer of toothbrushes had six different styles of toothbrushes, each with an ergonomic handle with soft rubber finger grips. They were looking for a feeder system that would sort, orient, and move the product to their laser etching and packaging...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

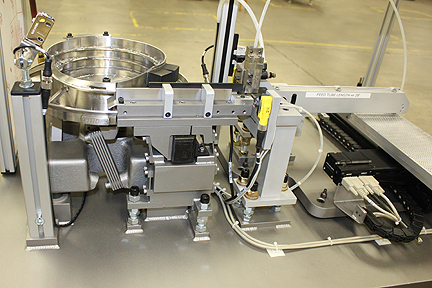

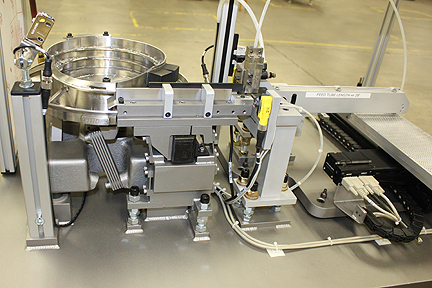

Problem: The customer was an integrator who was looking to replace a feeder system for a three-part automation system. The parts were constructed of steel, but were all dissimilar in geometry. The old system used three separate feeder bowls. It was the desire of...

by Fortville Feeders | Jun 26, 2019 | Escapements and Mechanisms

Problem: The customer was hand loading very small pins into a tray, with a matrix of pockets, for robotic pick up. Each tray held 1,380 pins. This was a tedious and time consuming process. The customer was seeking an automation solution to present the pins for...

by Fortville Feeders | Jun 26, 2019 | Escapements and Mechanisms

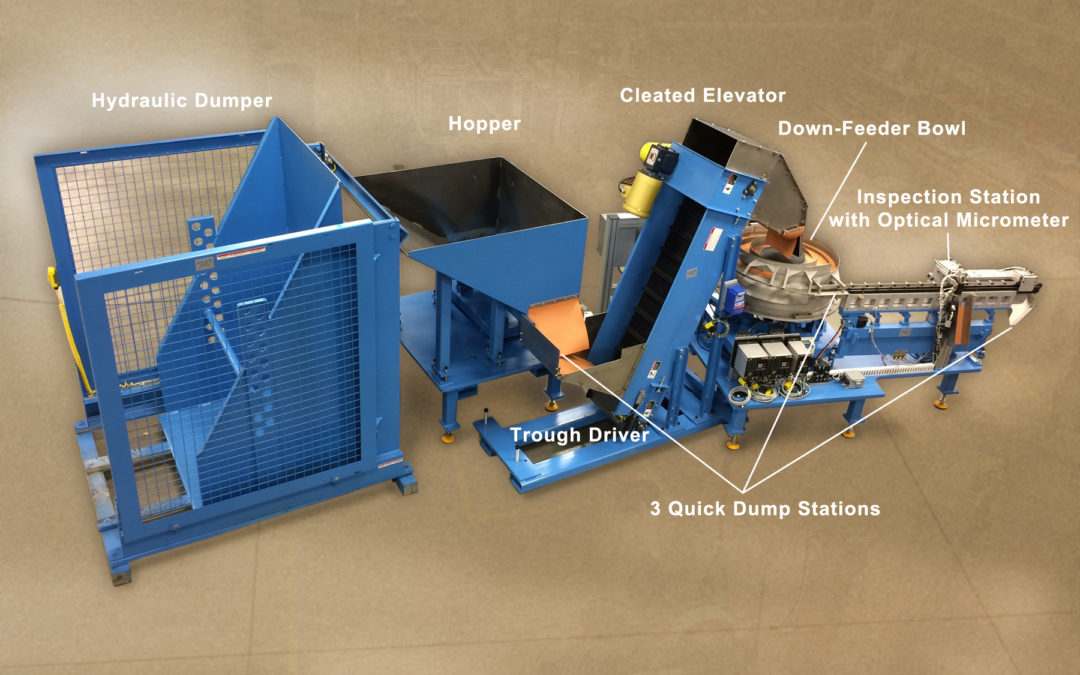

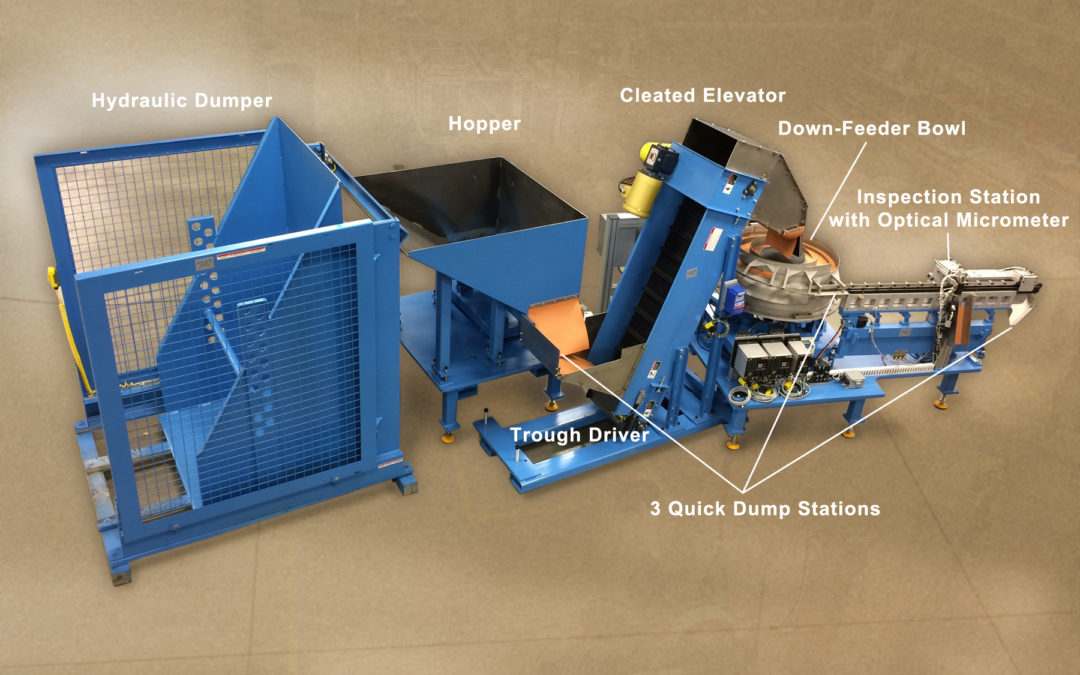

Problem The customer needed a way to feed large bolts of varying lengths to its heavy duty wheel hub assembly cell. They manufacture eight different axle assemblies, each with a different size wheel bolt. They needed a feeder system that could handle all eight...

Recent Comments