by Fortville Feeders | May 24, 2022 | Escapements and Mechanisms, Featured

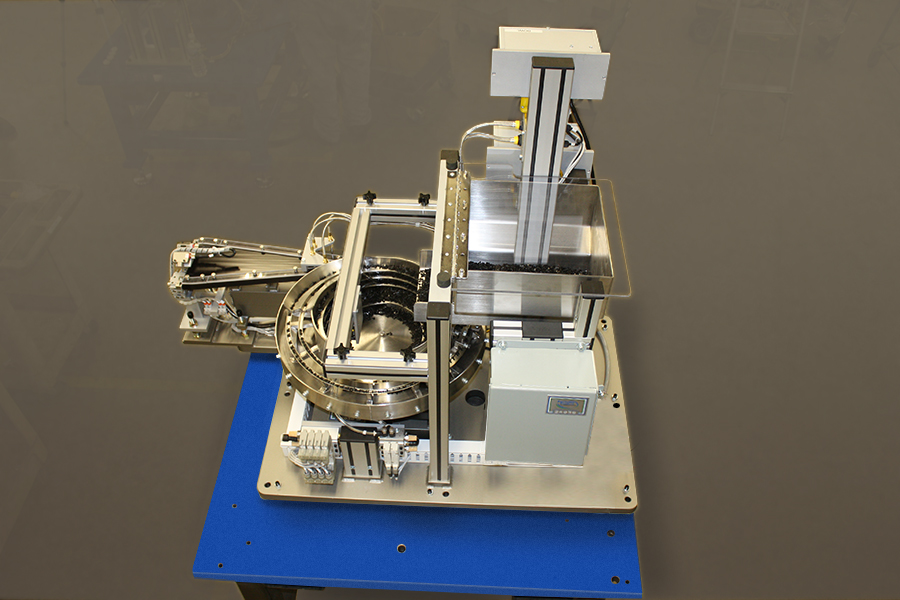

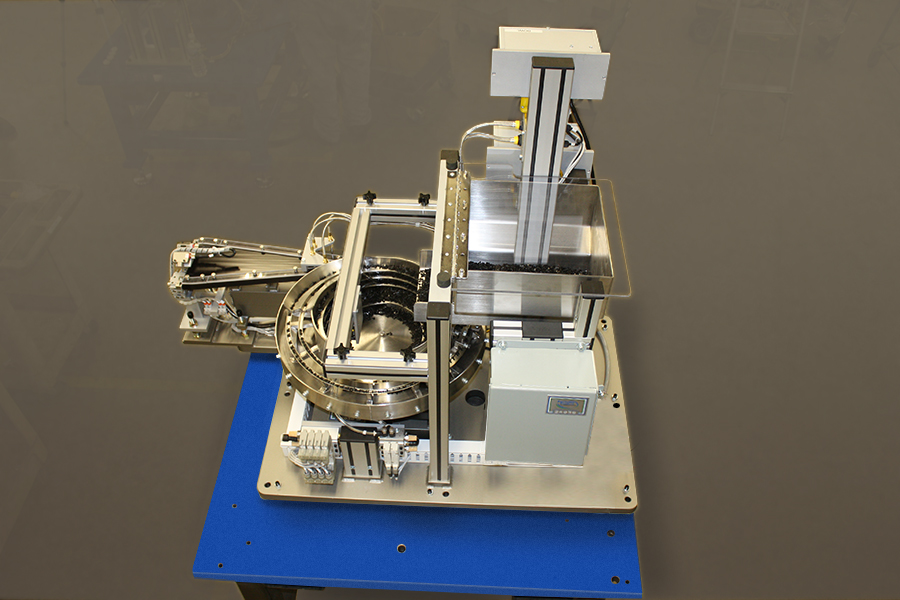

Problem: An integrator was looking for a way to feed tiny plunger parts. The parts had a flat, oblong head with a hole running through the length of the head. The parts needed to be presented to four pickup positions with the heads up and the holes facing forward. ...

by Fortville Feeders | Apr 16, 2022 | Escapements and Mechanisms, Featured, Tracking Systems

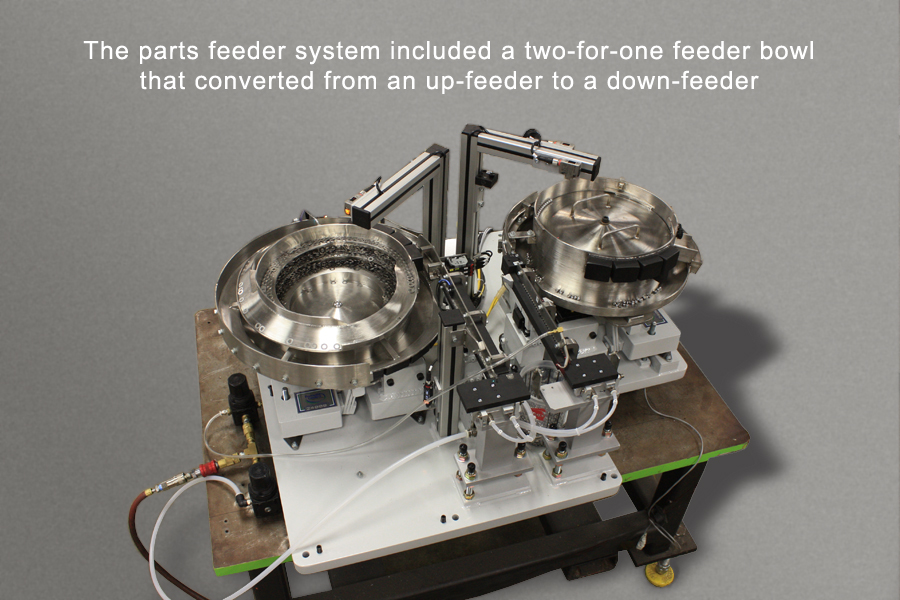

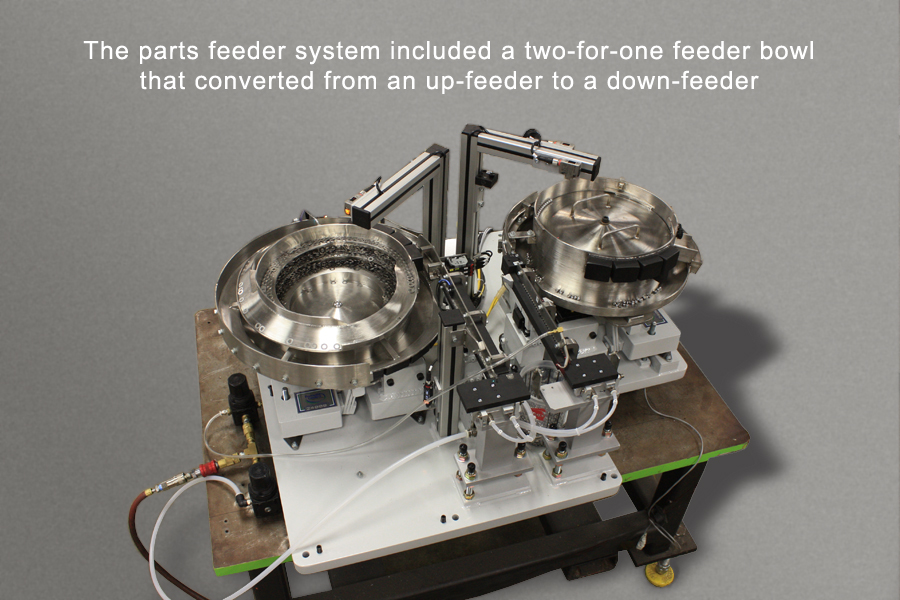

Problem: An integrator was looking for a new parts feeding system for their robot assembly of bearings. The client had two different bearing parts. One was fully round and the other was a half-round bearing. Both of these bearings were seated in a chamfered retainer...

by Fortville Feeders | Mar 22, 2022 | Featured, Hoppers

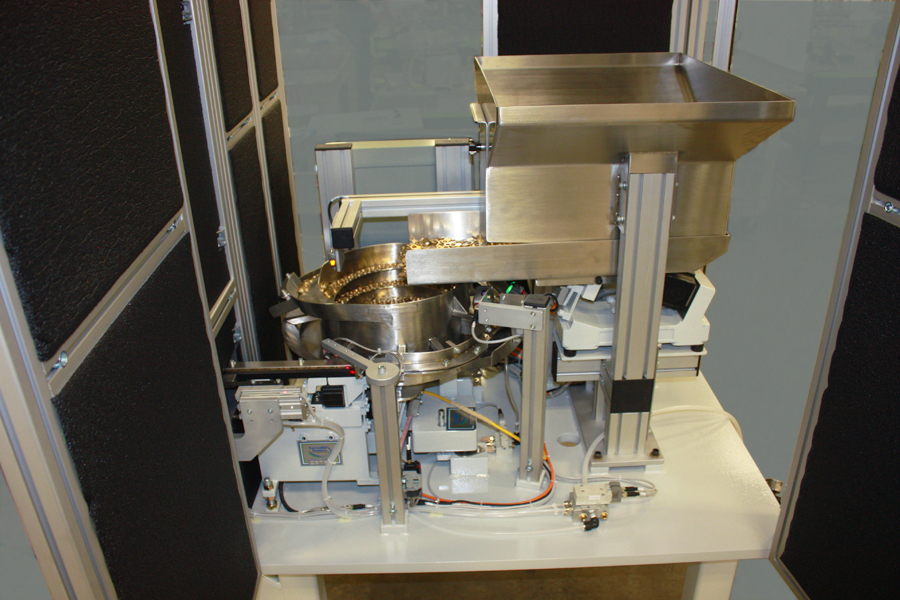

Problem: An integrator was looking for a solution to a parts handling issue. Large steel pipes were moved in a metal tub via a forklift to a loading station. They were looking for a way to safely load the heavy parts into a new vibratory parts feeder without tipping...

by Fortville Feeders | Feb 19, 2022 | Featured, High Speed Feeder Bowls

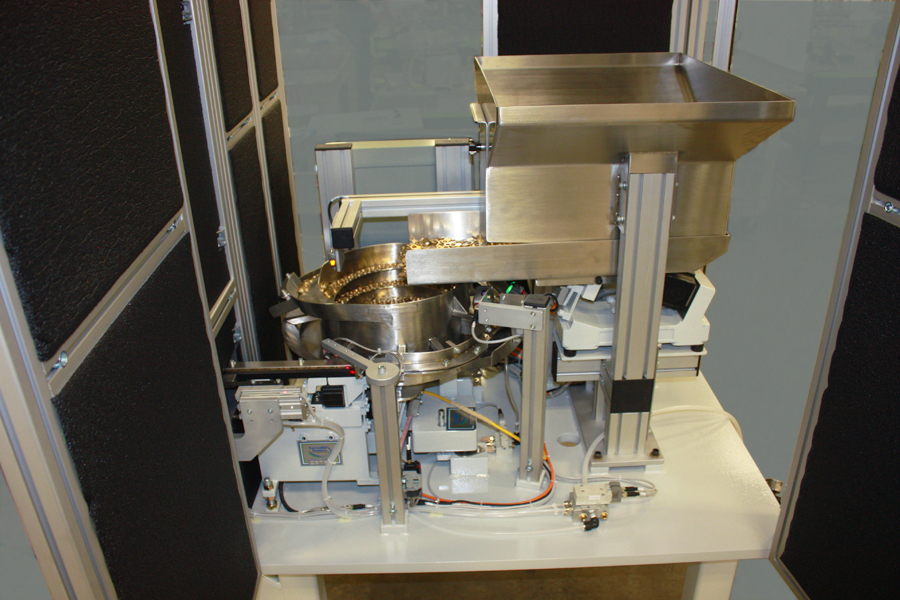

Problem: A manufacturer of metal components produces a conical spring and needed a feeder system that would handle bulk springs and deliver them at 140 parts per minute to their assembly station. The problem was the springs were easily tangled in bulk situations. The...

by Fortville Feeders | Dec 10, 2021 | Escapements and Mechanisms, Featured

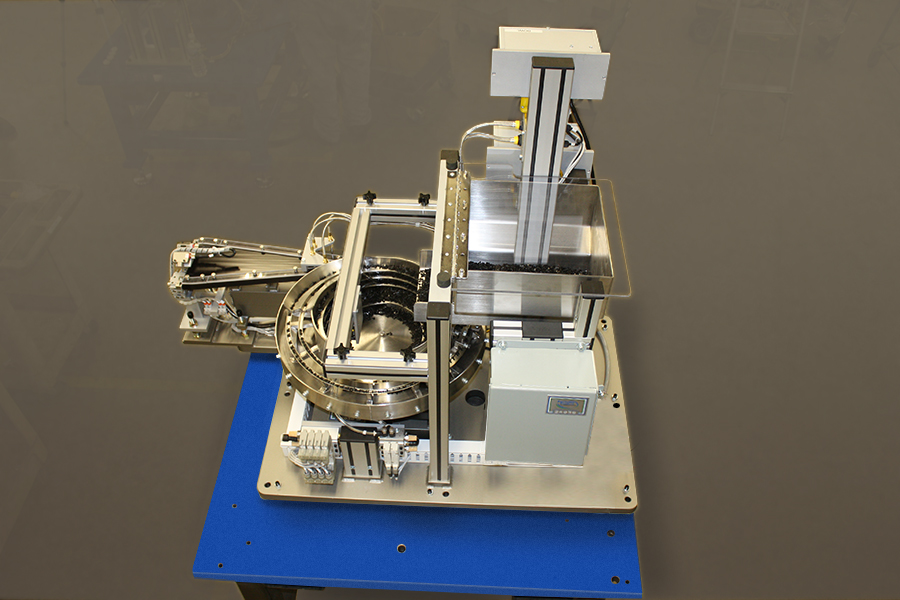

Problem: The manufacturer of door hardware was in need of a way to automate the orientation and feeding of three different brass lock components for an assembly cell. The parts all shared the same two-lobe shape with one lobe having a hole and one being solid. Two of...

Recent Comments