by Fortville Feeders | Feb 12, 2021 | Escapements and Mechanisms, Featured

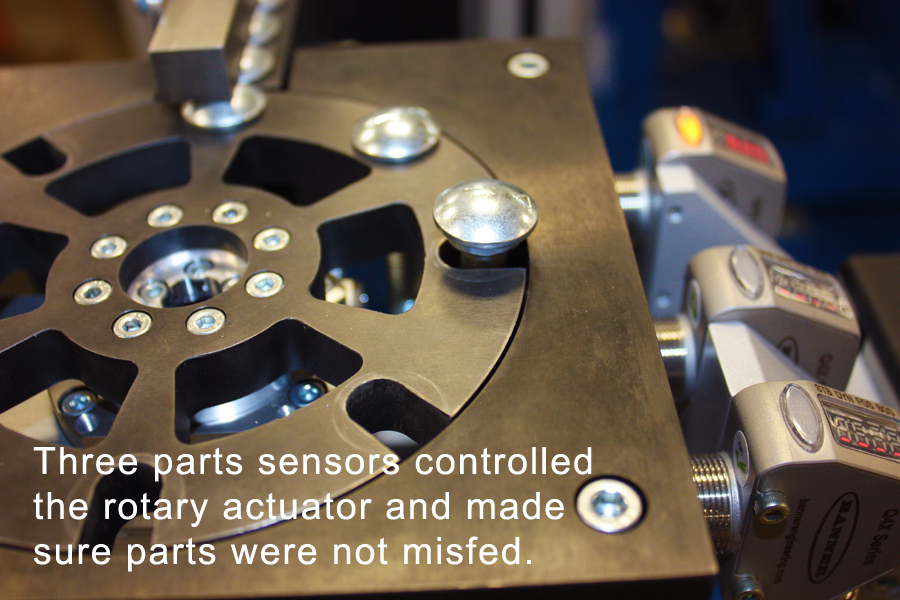

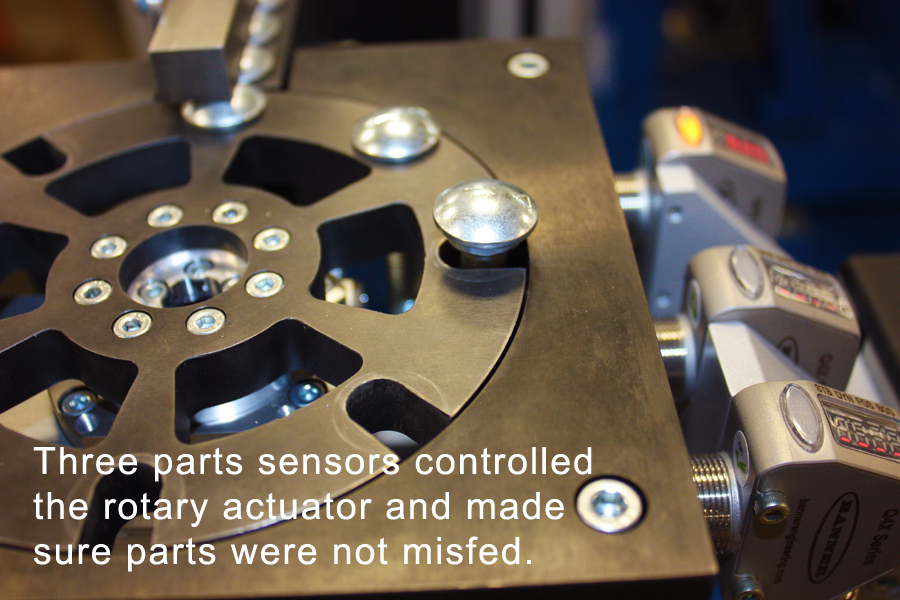

Problem: An integrator was building an automated assembly system for a manufacturing customer. They needed a parts feeder for a heavy metal fastener that was picked up by a robotic arm and assembled. There were two issues of concern. First, the part had to be...

by Fortville Feeders | Jan 15, 2021 | Escapements and Mechanisms, Featured

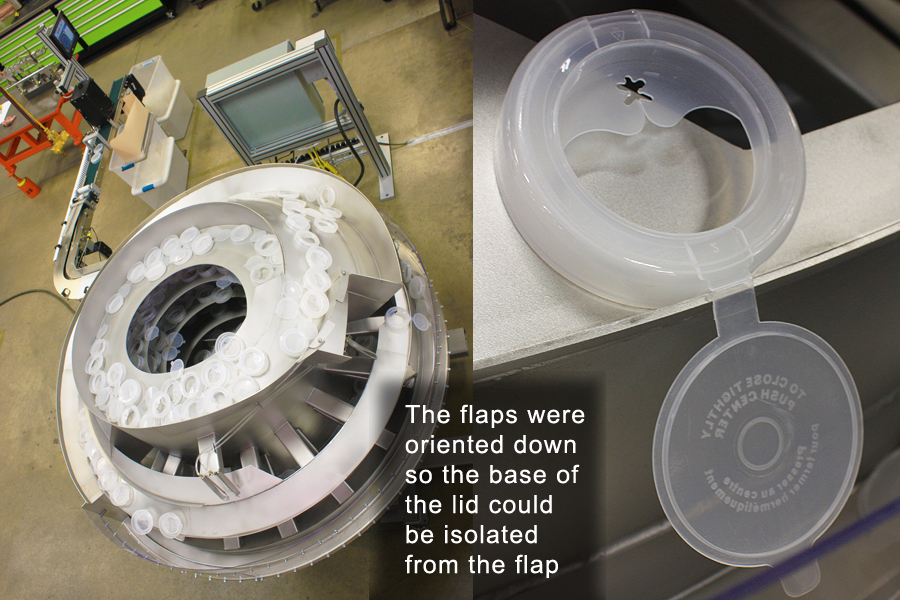

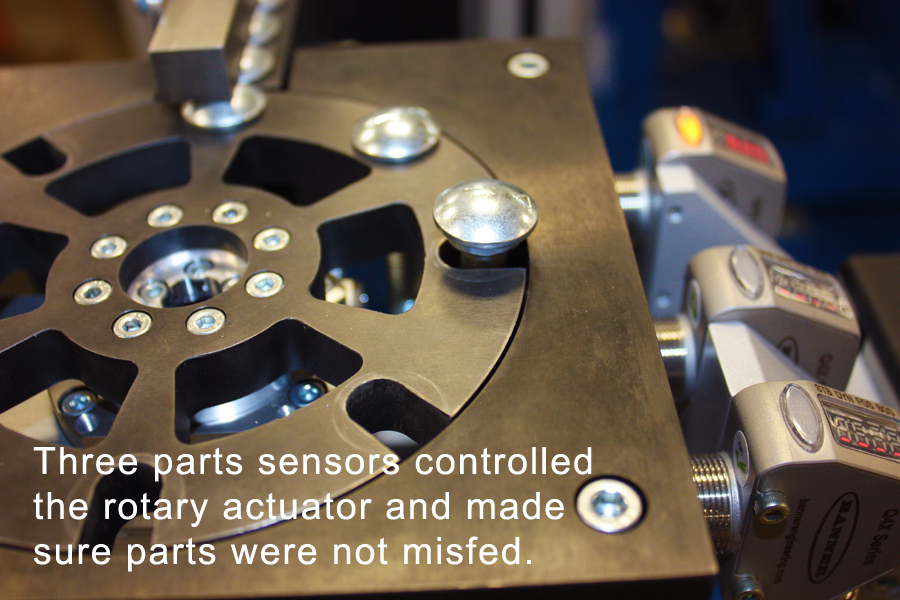

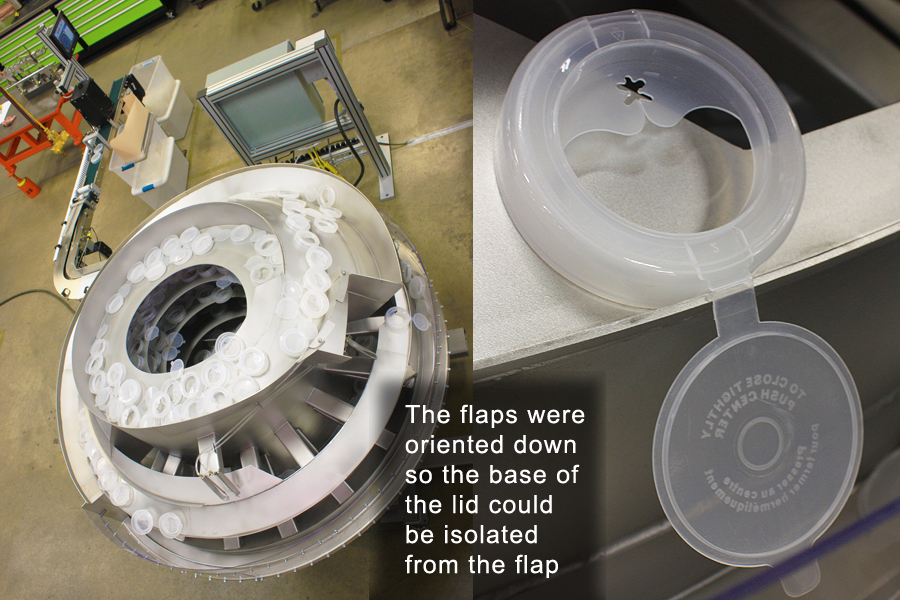

Problem: A packaging manufacturer for disinfectant wipes needed to develop a new feeder system to handle their double seal lids. Demand for the product made it necessary to build a new line. The plastic lids were required to be fed at a high rate to the customer’s...

by Fortville Feeders | Nov 13, 2020 | Featured, Tracking Systems

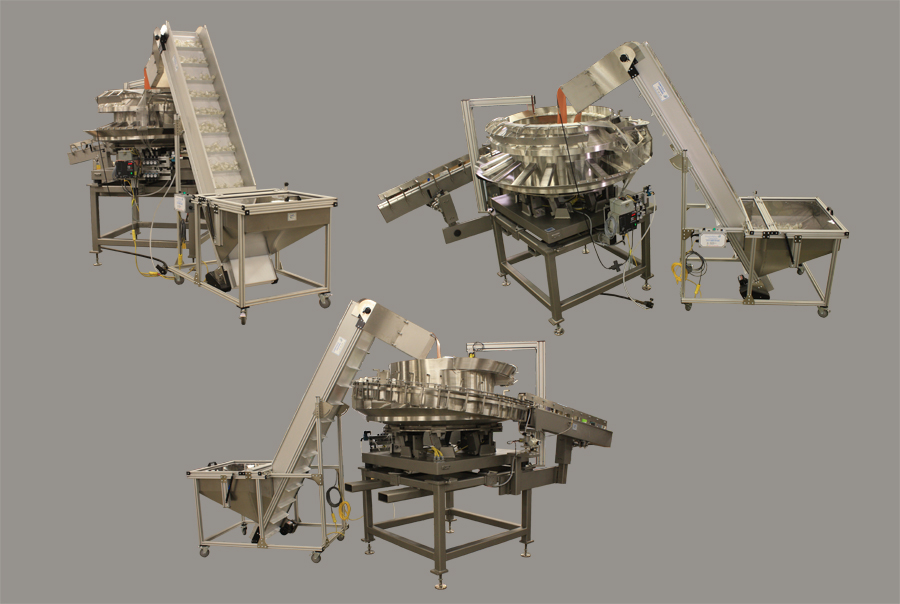

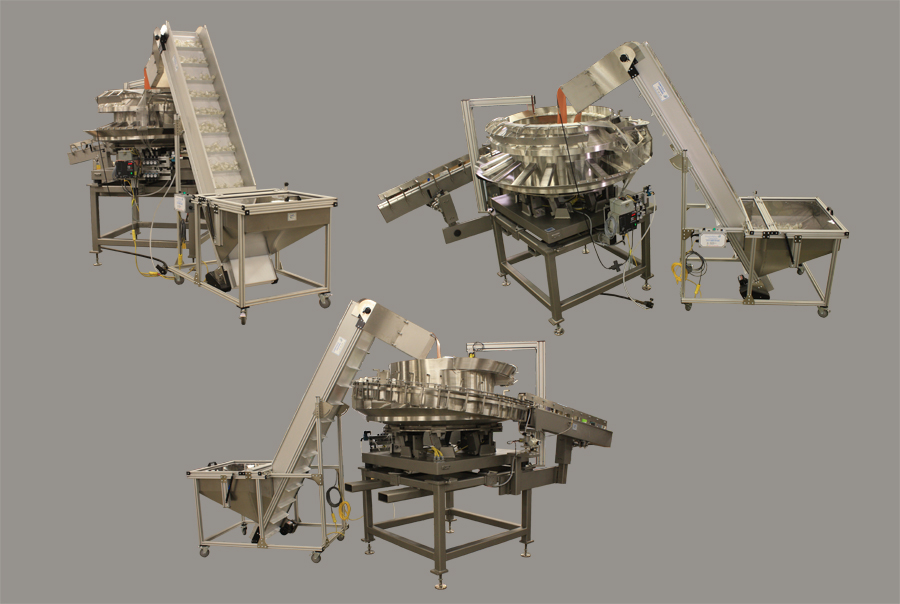

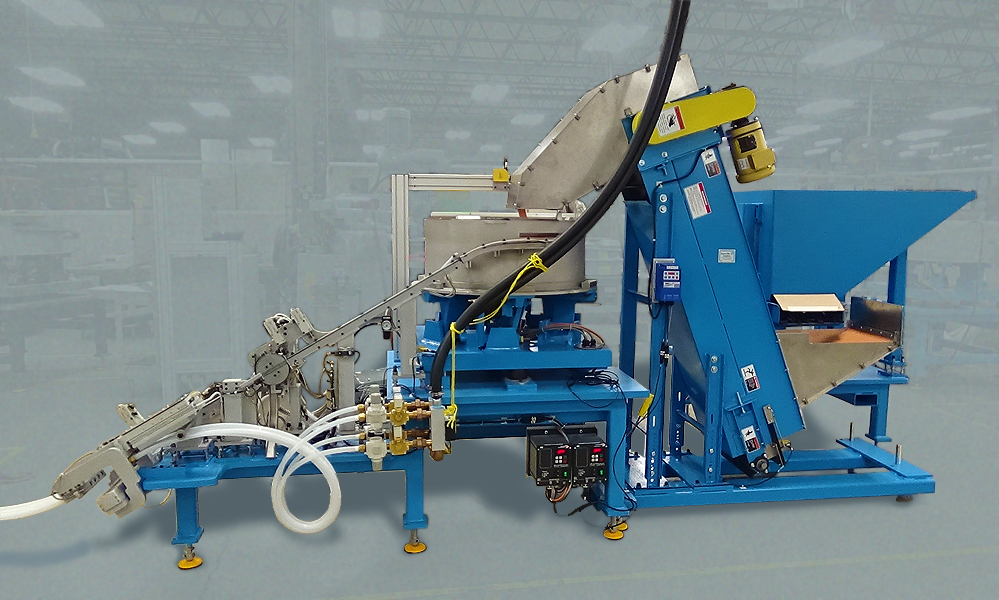

Problem: The manufacturer of hand sanitizer bottles desired a single feeder system for multiple foaming pump nozzles for their automated bottling assembly station. They had five different pump nozzles that were of different sizes and geometries. Some of these pump...

by Fortville Feeders | Oct 20, 2020 | Escapements and Mechanisms

Problem: A manufacturer of auto engine components was having trouble finding enough qualified laborers to assemble their solenoid housing units. They wished to automate the pre-welding assembly of two parts. These had previously been hand assembled before being picked...

by Fortville Feeders | Sep 29, 2020 | Escapements and Mechanisms

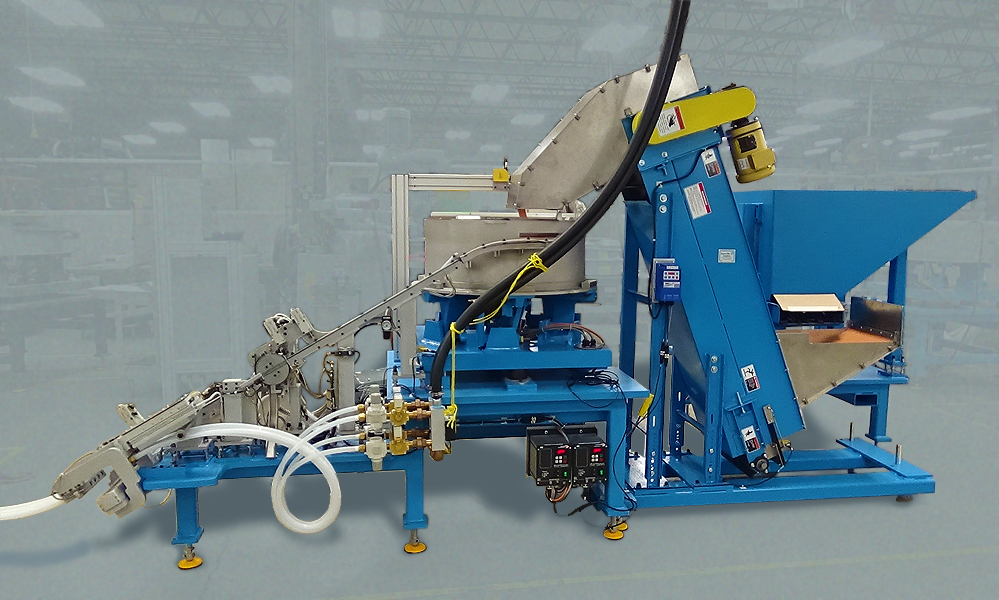

Problem: The customer was an integrator working for a manufacturer of heavy truck axles. They needed a parts feeder system for their assembly automation that would be able to handle three different axle studs. Each was of a different length. Each of the studs had a...

Recent Comments