by Fortville Feeders | Aug 11, 2020 | Escapements and Mechanisms, Featured, Tracking Systems

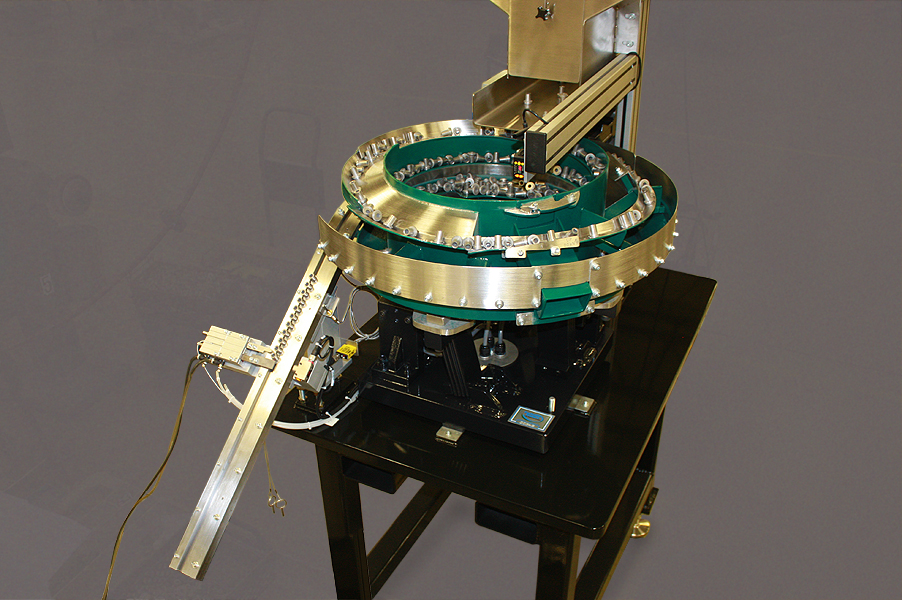

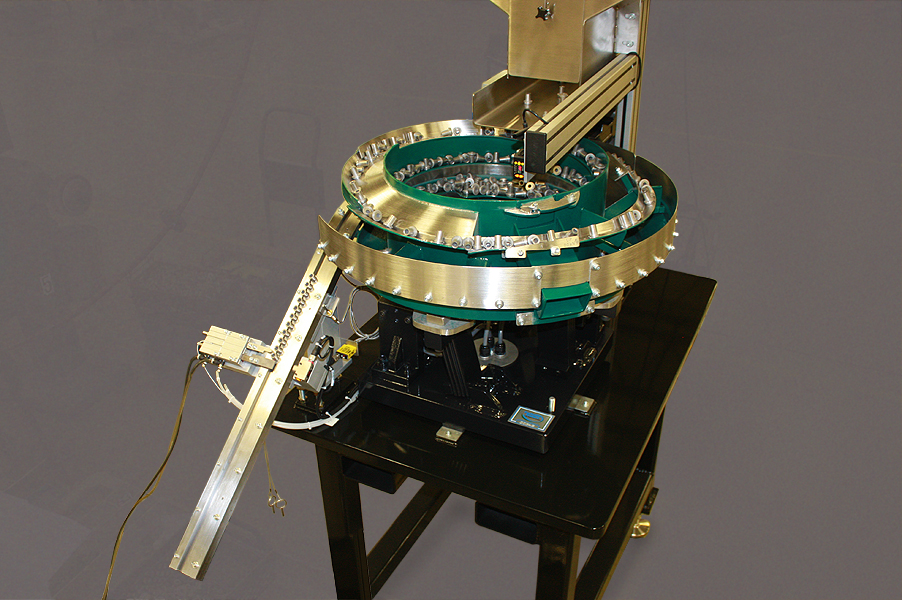

Problem: A manufacturer needed a feed system to supply 10 spacers of various thicknesses to be used in the assembly of mechanical components. The spacers were picked and placed by robots that could be programmed to select any of the 10 spacers needed for the assembly....

by Fortville Feeders | Jun 11, 2020 | Escapements and Mechanisms, Featured

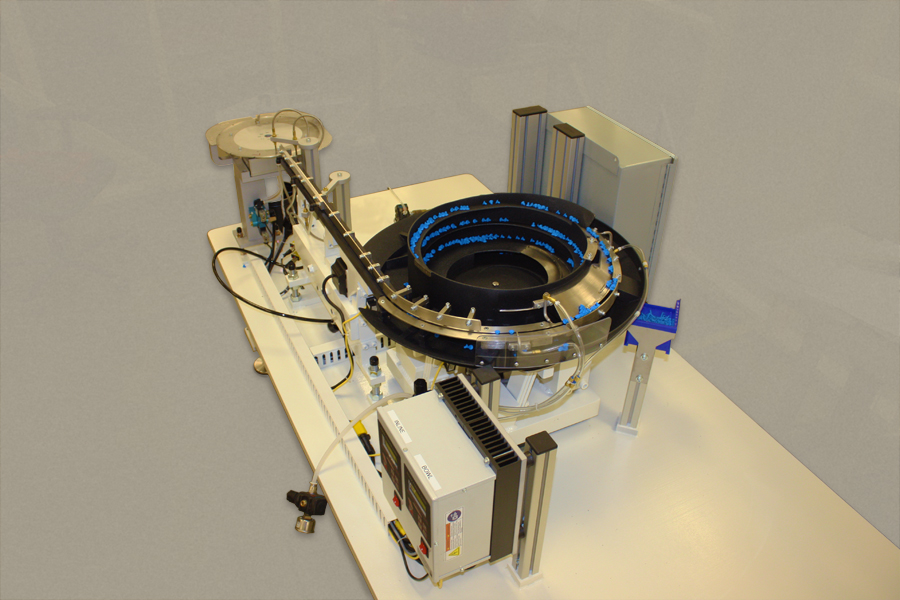

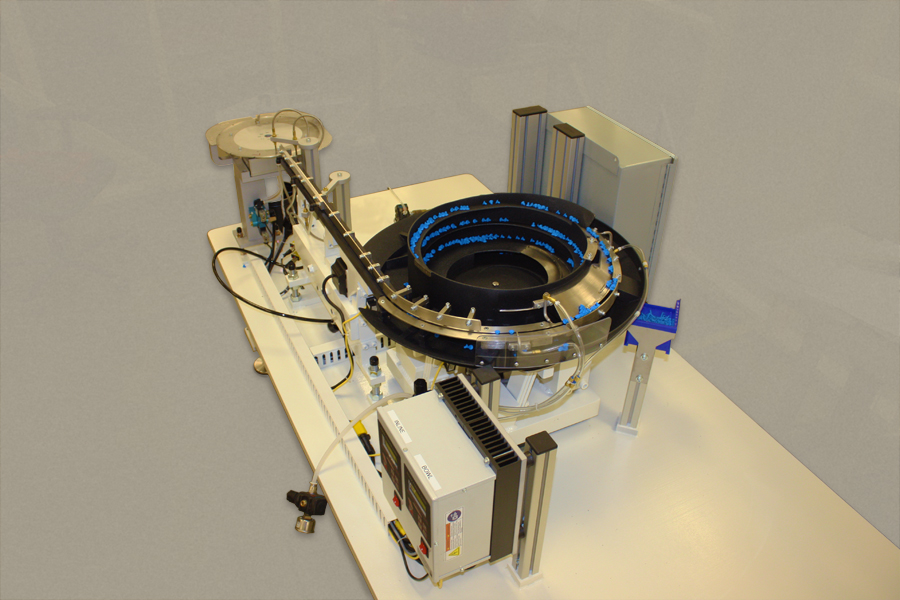

A manufacturer of valves needed an automated part feeding solution for a rubber insert that was a component of the product assembly. Fortville Feeders designed a vibratory inline feeder that fed a rotary actuator. The wheel handed parts off to the customer’s pick and...

by Fortville Feeders | Apr 9, 2020 | Featured, Feeder Bowls

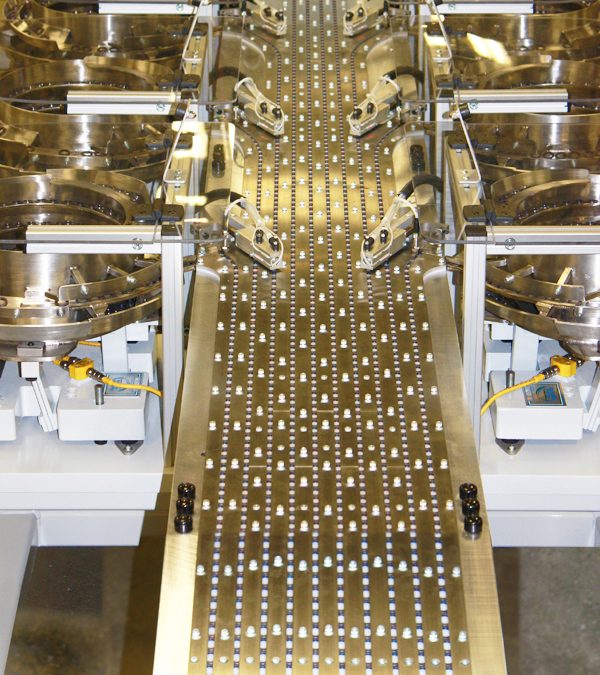

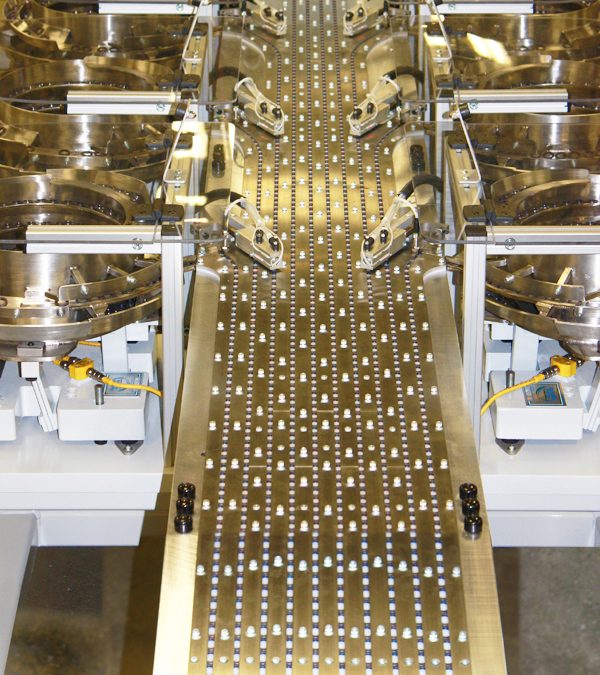

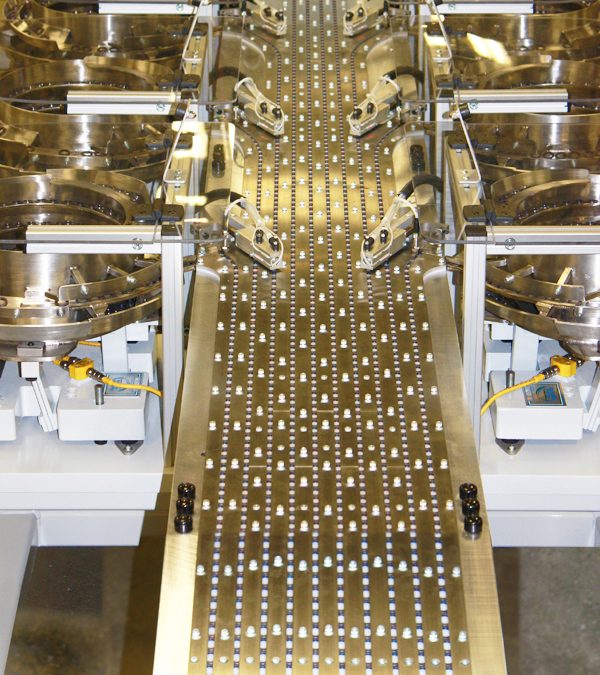

Problem: A medical packaging integrator was in need of bulk feeder systems for their vial assembly operations. They had a contract with a worldwide leader in biotechnical and pharmaceutical testing to integrate eight new parts feeder systems into their existing...

by Fortville Feeders | Mar 12, 2020 | Tracking Systems

Problem: An integrator was building a parts resonance testing machine that checked powdered metal parts for defects. Powdered or sintered metal is prone to inclusions – cracks or pockets where air is trapped which weakens the structural integrity of the part....

by Fortville Feeders | Feb 12, 2020 | High Speed Feeder Bowls, Tracking Systems

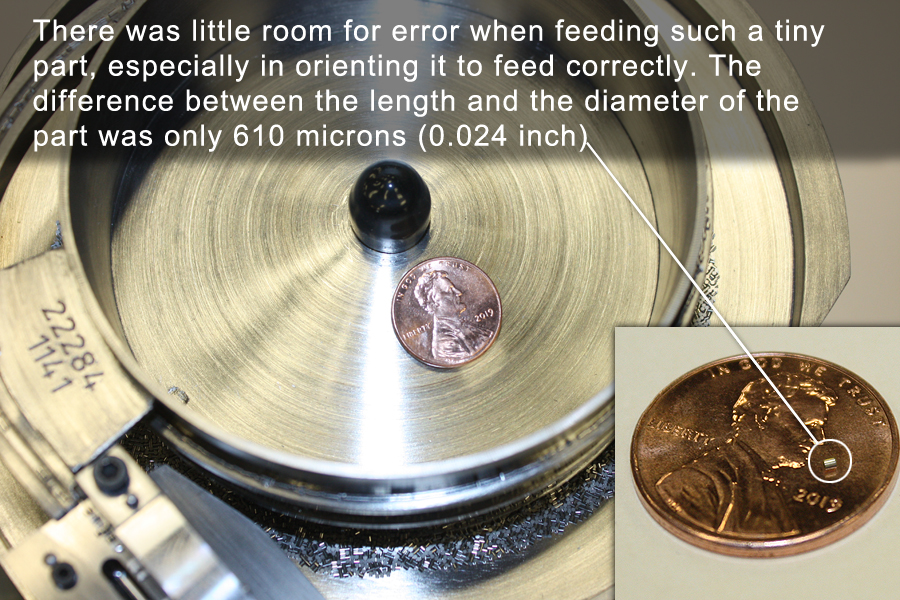

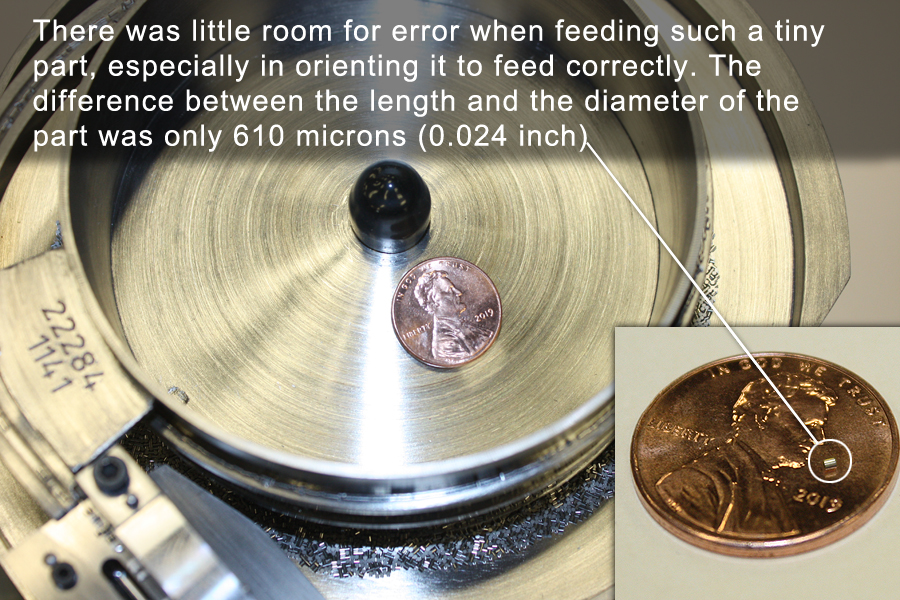

Problem: Fortville Feeders will service any feeder system, regardless of its manufacturer. On one such service call to the manufacturer of spark plugs, the customer was having trouble getting a very small iridium electrode to feed correctly. The electrodes were...

Recent Comments