by Kevin Yaney | Feb 5, 2024 | Escapements and Mechanisms, Featured

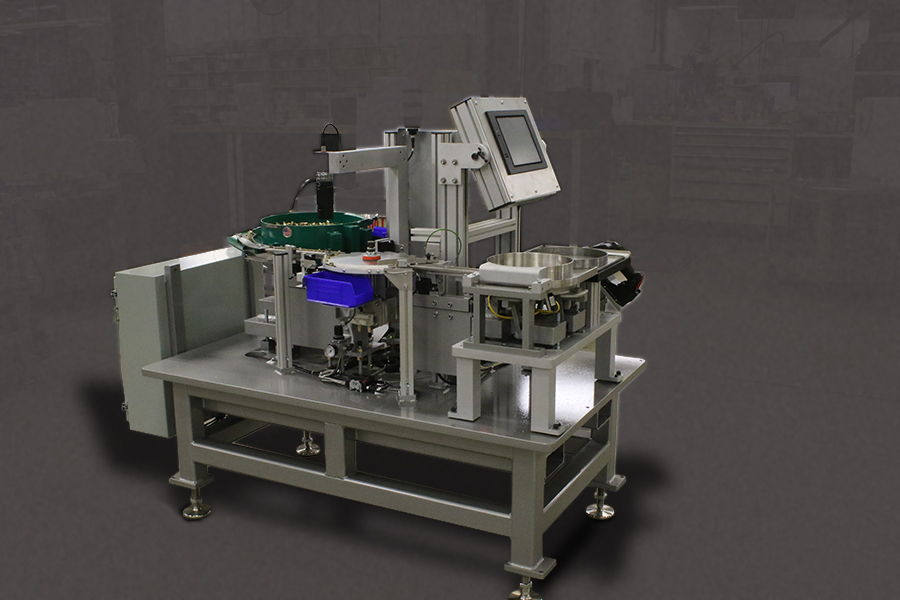

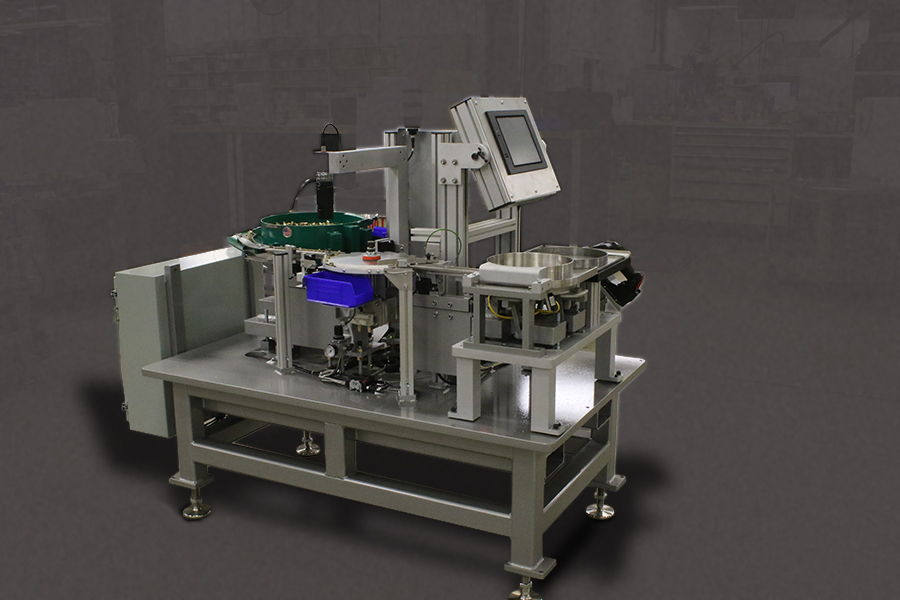

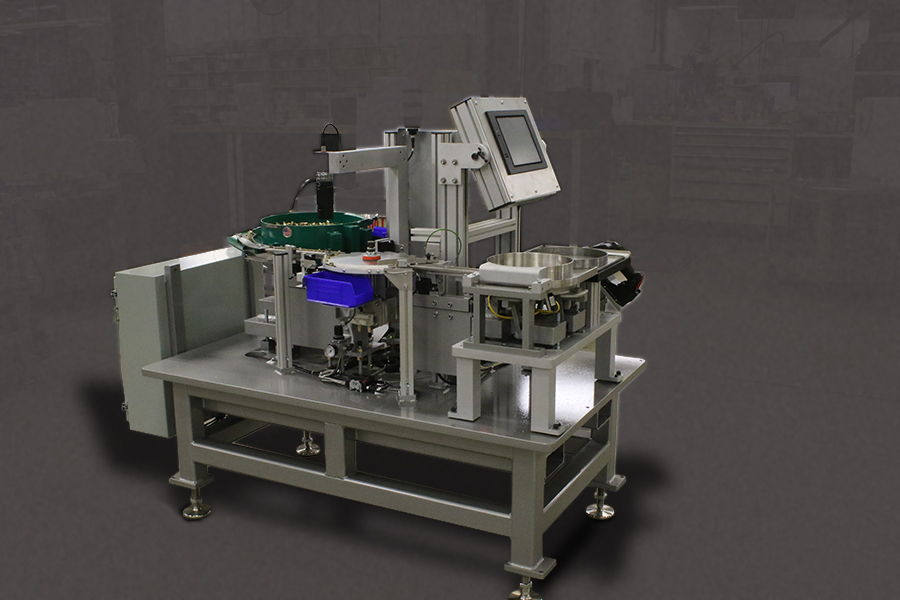

Problem: A manufacturer was using a two-step process to inspect and accumulate parts prior to the final machining operation. The process required double the manpower and introduced possible errors by mishandled parts. Each part was presented to a camera and another...

by Kevin Yaney | May 4, 2023 | Uncategorized

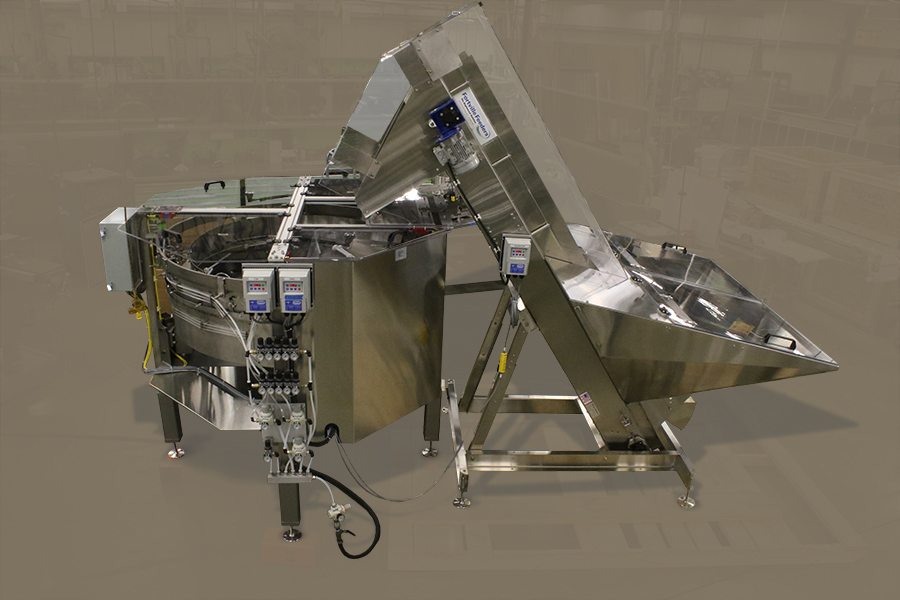

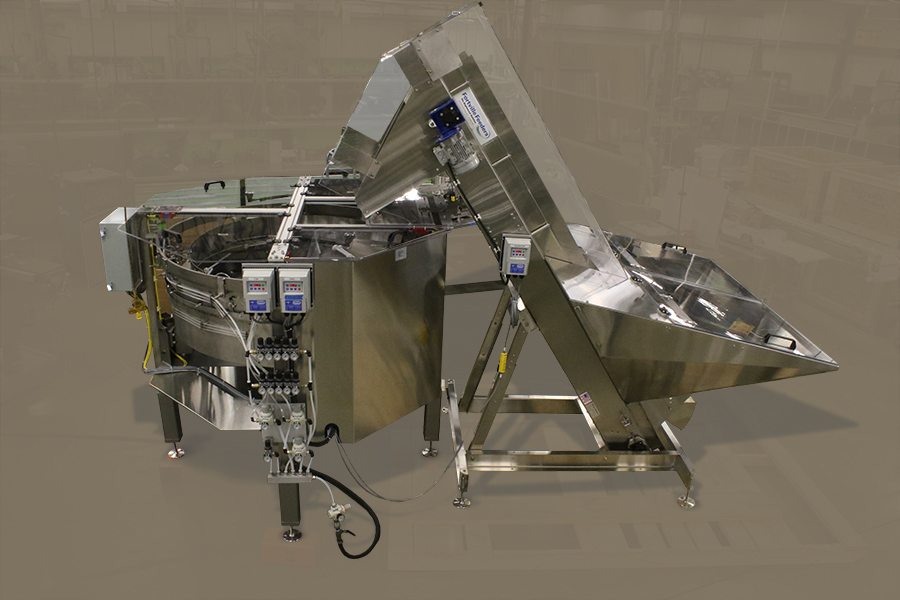

Problem: An integrator was in need of a high-speed parts feeder for a plastic pump and cap for a bottling assembly station. The customer had used a centrifugal feeder in the past and desired to have a duplicate machine built. In this case, the customer needed a system...

by Kevin Yaney | Mar 25, 2021 | Featured, Tracking Systems

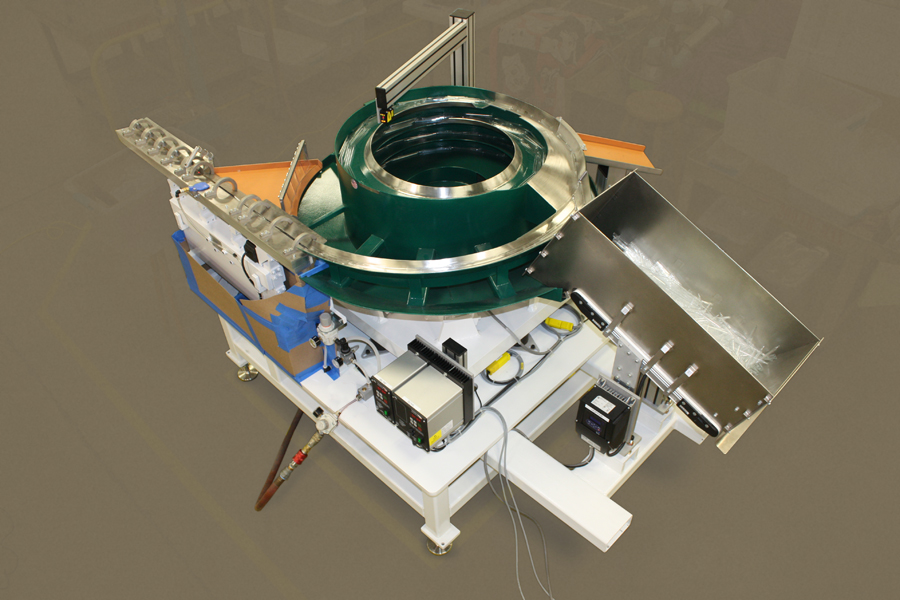

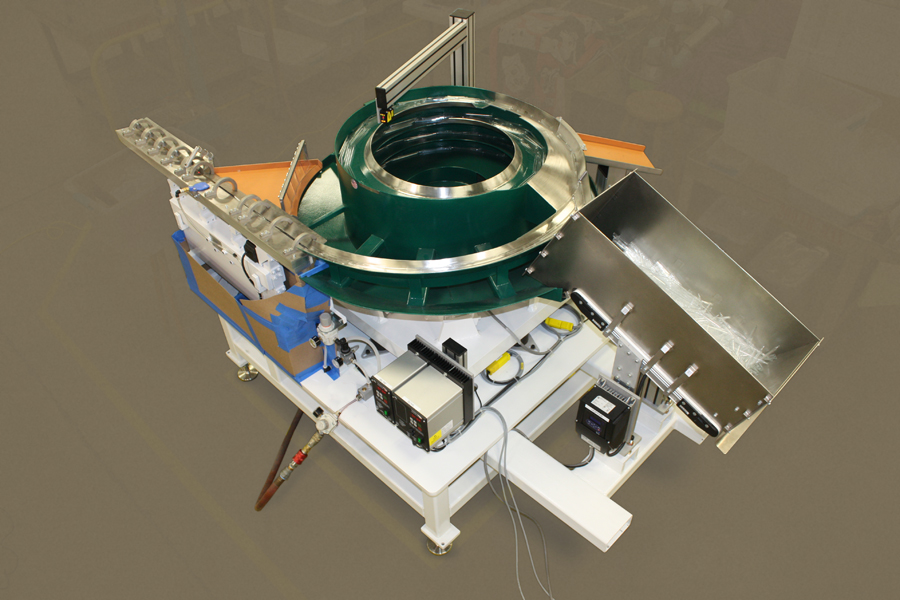

Problem: An integrator was building an automated system that packaged five different sizes of medical glass pipettes. The pipettes were very fragile and had to be gently handled, but delivered at 80 parts per minute. This included bulk loading of the parts, moving...

by Kevin Yaney | Aug 25, 2020 | High Speed Feeder Bowls, Tracking Systems

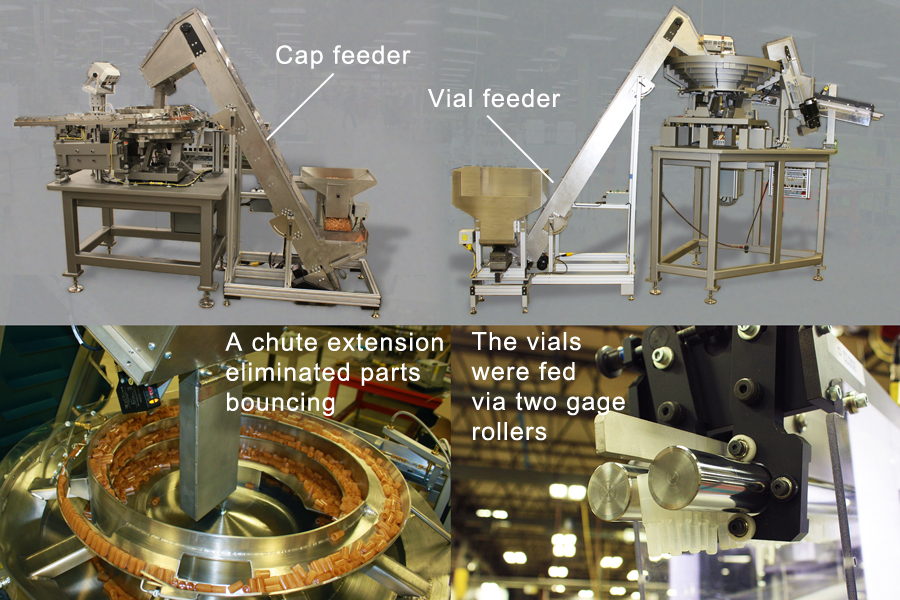

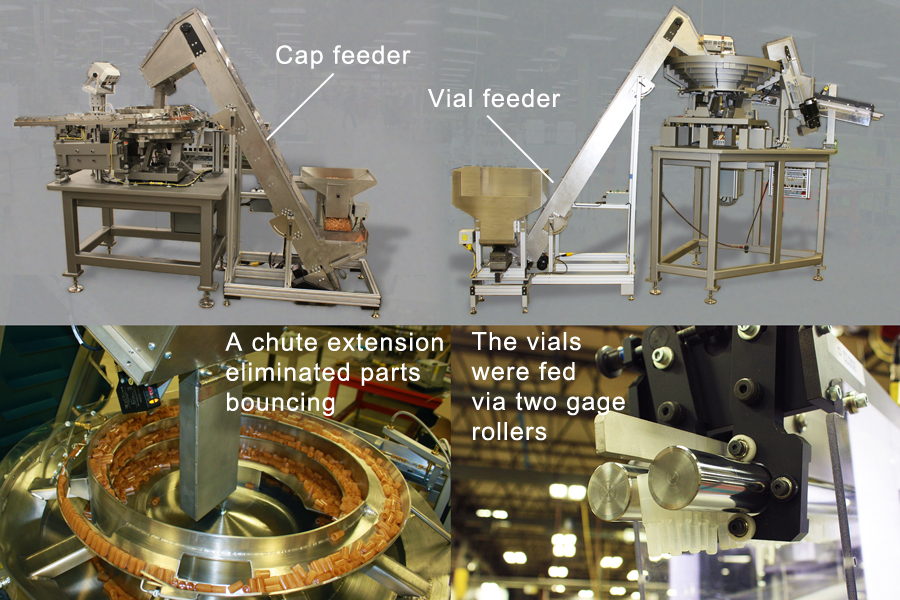

Problem: An integrator was building an assembly and labeling automation system for a medical packaging company. The high-speed system labeled vials and capped them before being filled. The customer needed two feeder systems; one for the vials and one for the caps,...

by Kevin Yaney | Apr 23, 2020 | Uncategorized

Introduction: An integrator located in Montreal, Canada needed a manufacturer to both produce and provide service on vibratory feeder systems. Even though the integrator typically does all of their own parts feeding systems on the automated machinery they produce,...

Recent Comments