by Kevin Yaney | Feb 25, 2020 | Escapements and Mechanisms, Featured

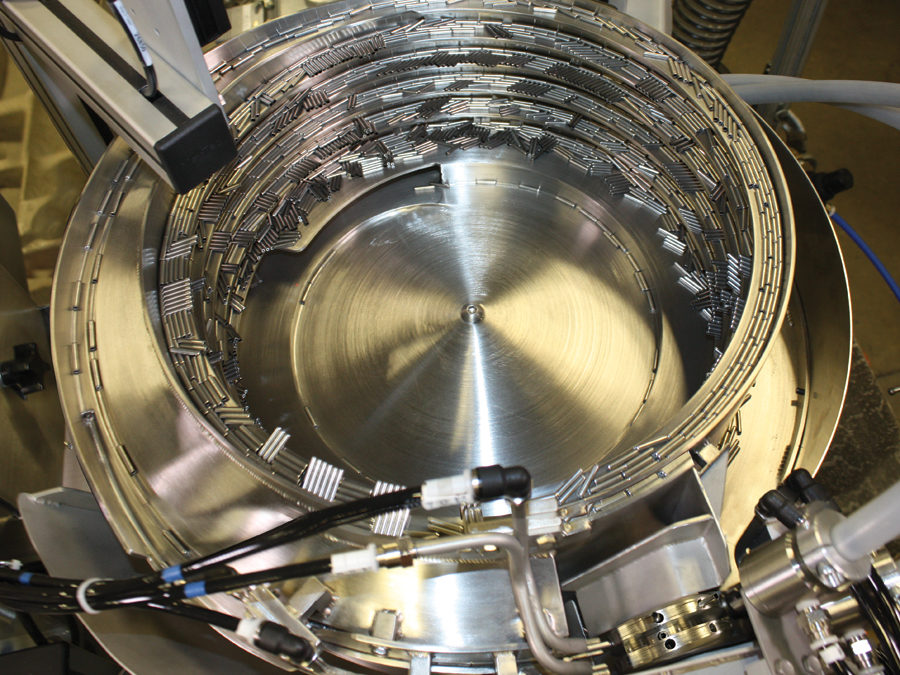

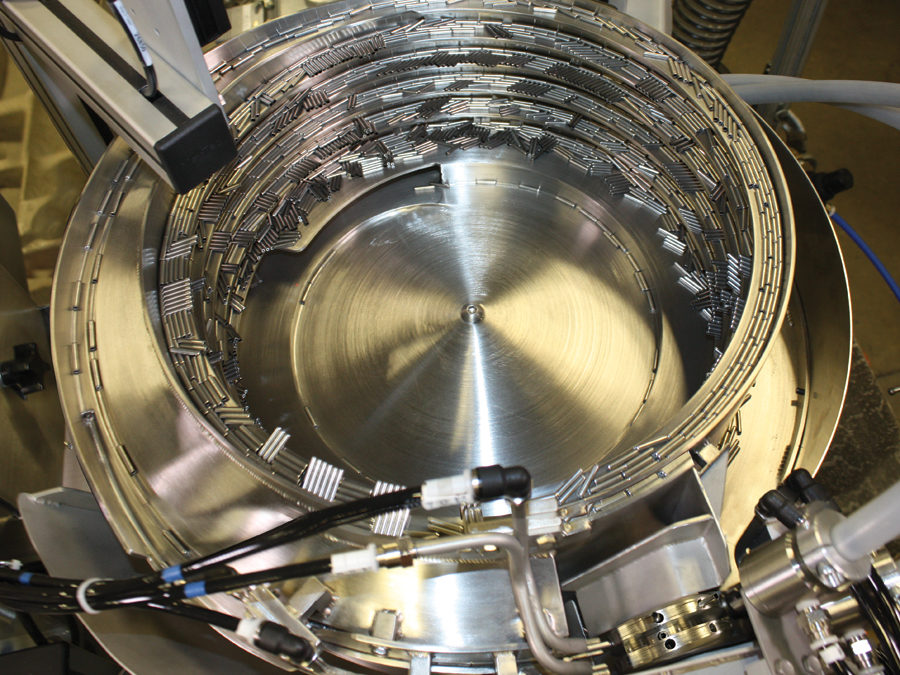

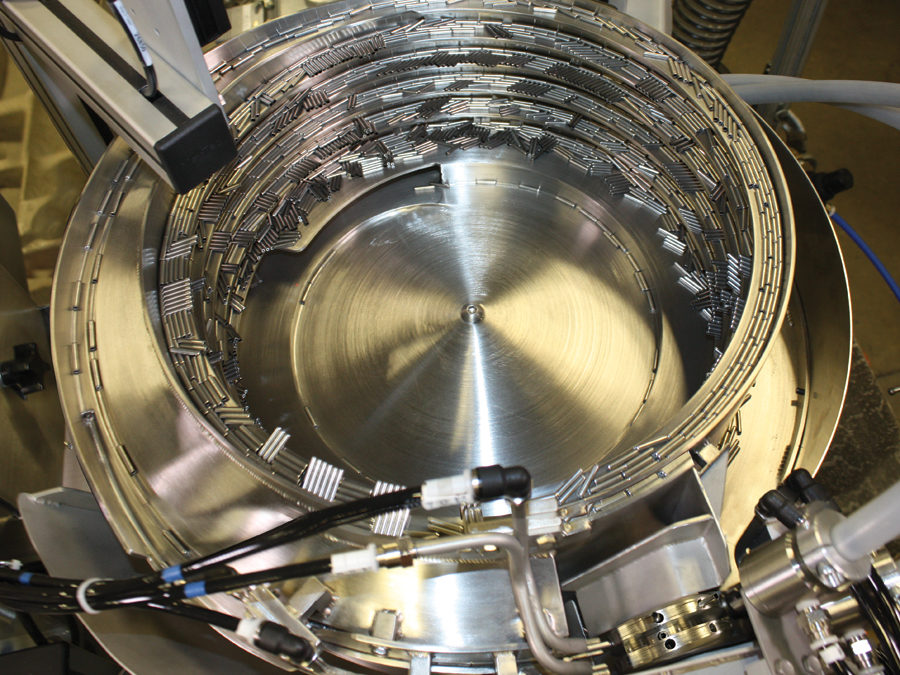

Problem: The manufacturer of critical control products was looking for a way to feed bulk pins to an assembly robot. The pins were small and, other than large and small openings at opposite ends, had no other distinguishing features. It was critical that the pins be...

by Kevin Yaney | Jan 24, 2020 | Featured, Feeder Bowls

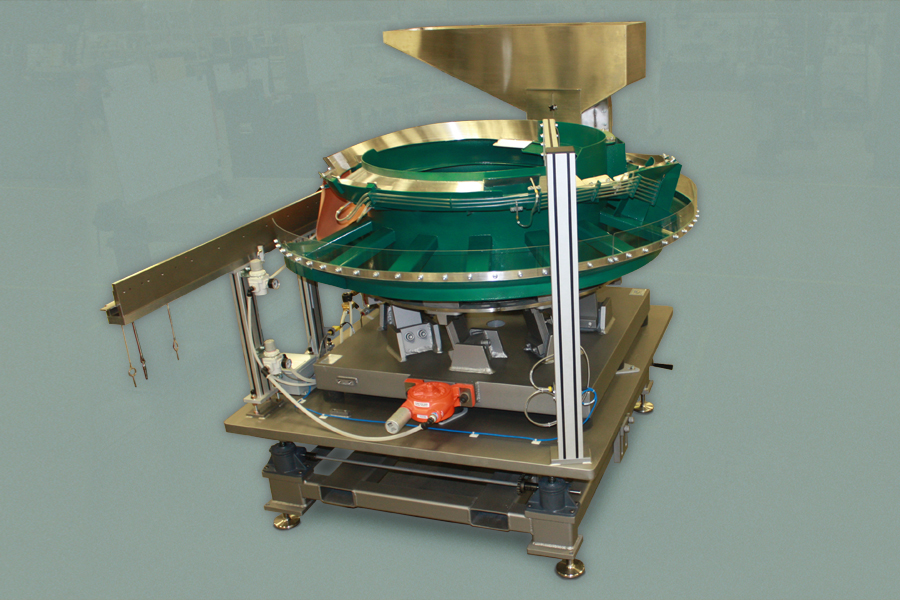

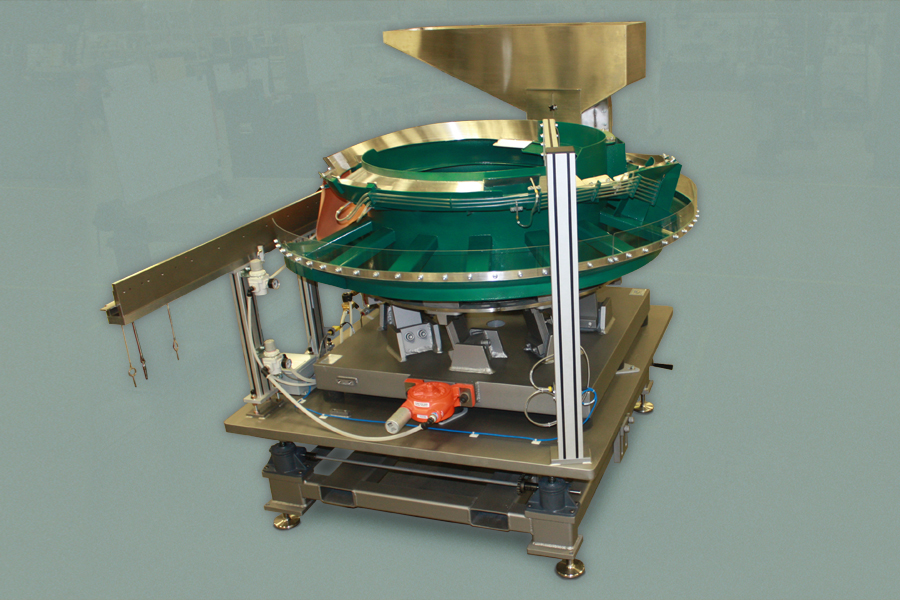

Problem: The customer was bottling highly combustible consumer products in aerosol cans. They needed an automated feeder system to handle five different caps for these cans. The feeder had to orient and move the parts at a high speed, but more importantly, it had to...

by Kevin Yaney | Nov 22, 2019 | Escapements and Mechanisms

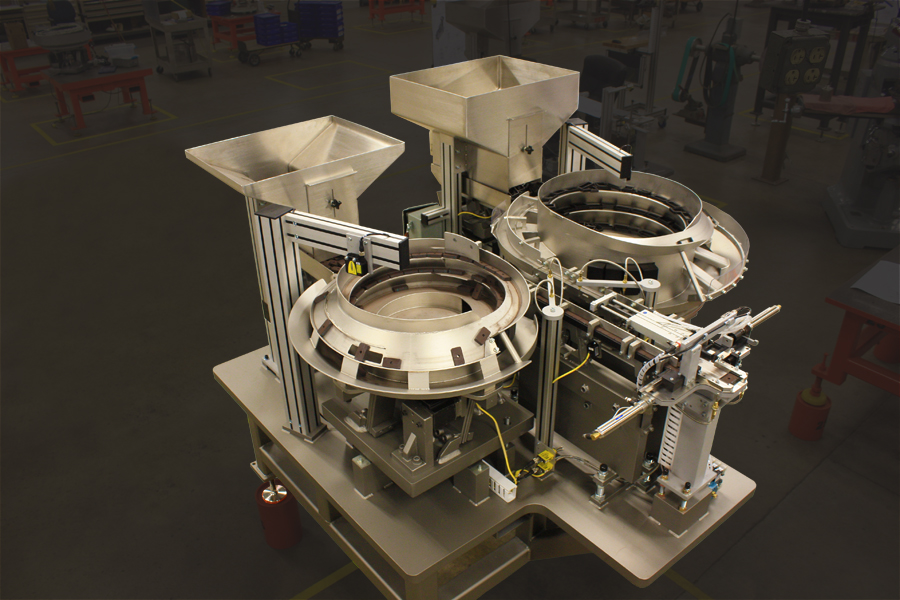

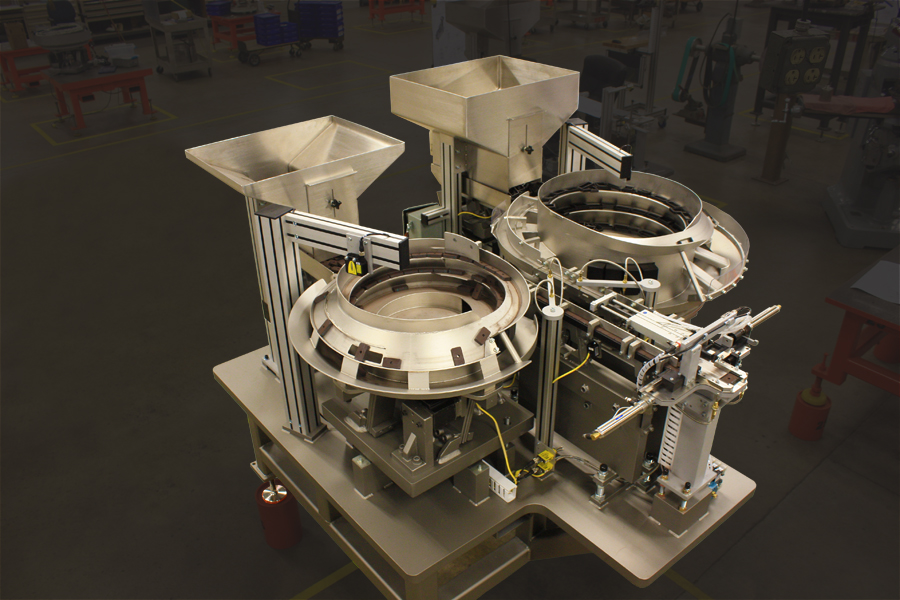

Problem: A lawnmower manufacturer needed to update a parts feeder on their assembly line. The equipment fed two components of a magneto to a robot. The two parts needed to be assembled, with a magnet placed inside a plastic holder before the robot picked it up....

by Kevin Yaney | Nov 5, 2019 | Feeder Bowls, Tracking Systems

Problem: The manufacturer of water treatment control valves was looking for a way to automate their parts feeding and loading system that would continuously feed five conveyors that supplied their assembly station. The loading had previously been done by hand. The...

by Kevin Yaney | Sep 24, 2019 | Tracking Systems

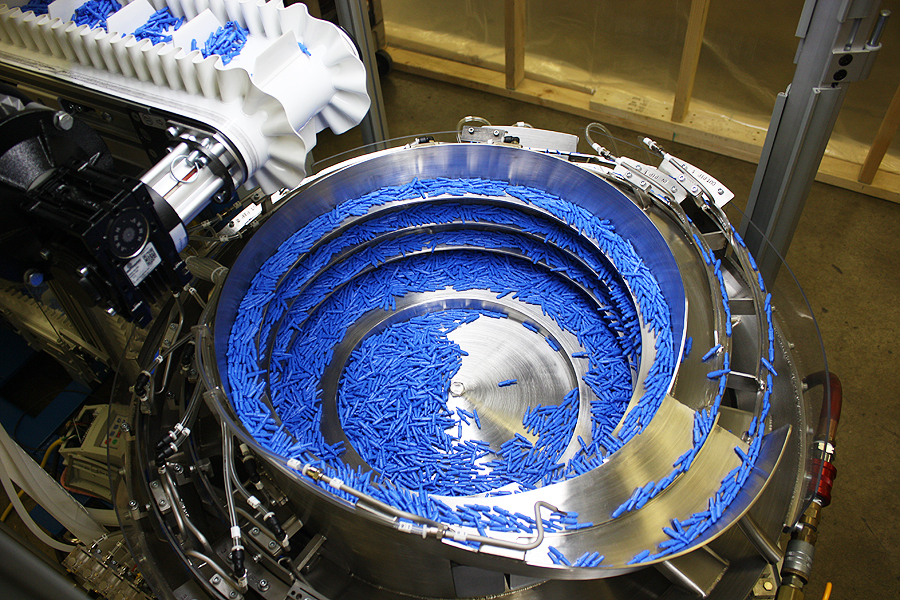

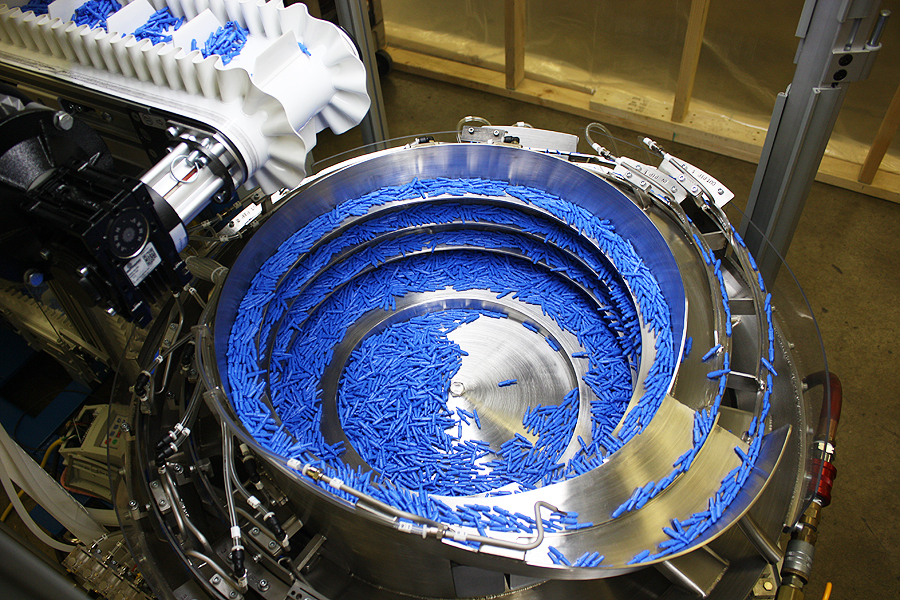

Problem: A manufacturer of ear protection devices needed two small parts – stems for earplugs – fed to their assembly equipment at a high rate of speed. The plastic stems had to be oriented properly, with the smaller diameter end leading. Any damaged or...

Recent Comments