by Kevin Yaney | Feb 25, 2020 | Escapements and Mechanisms, Featured

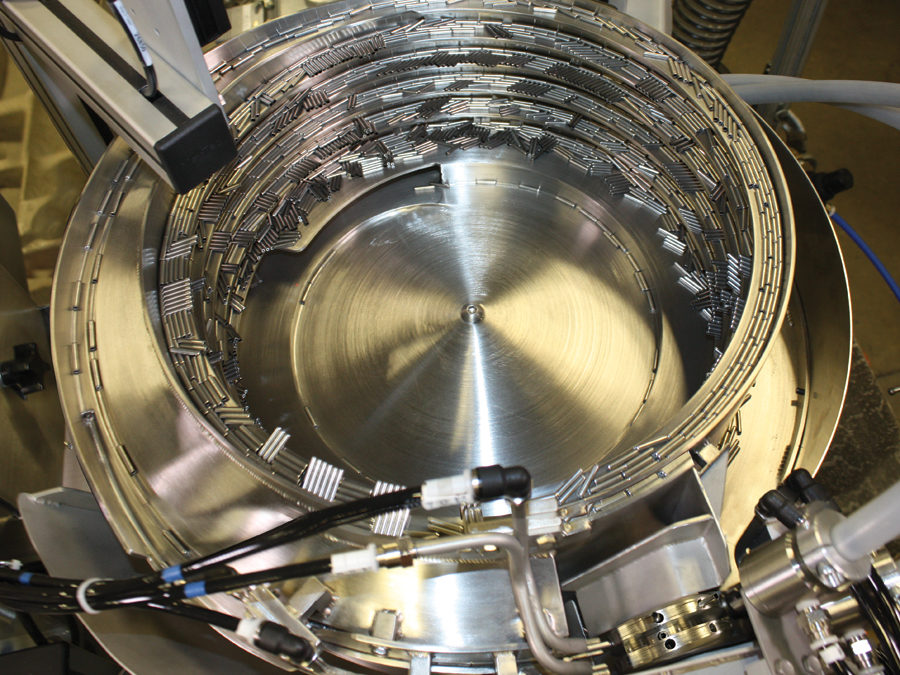

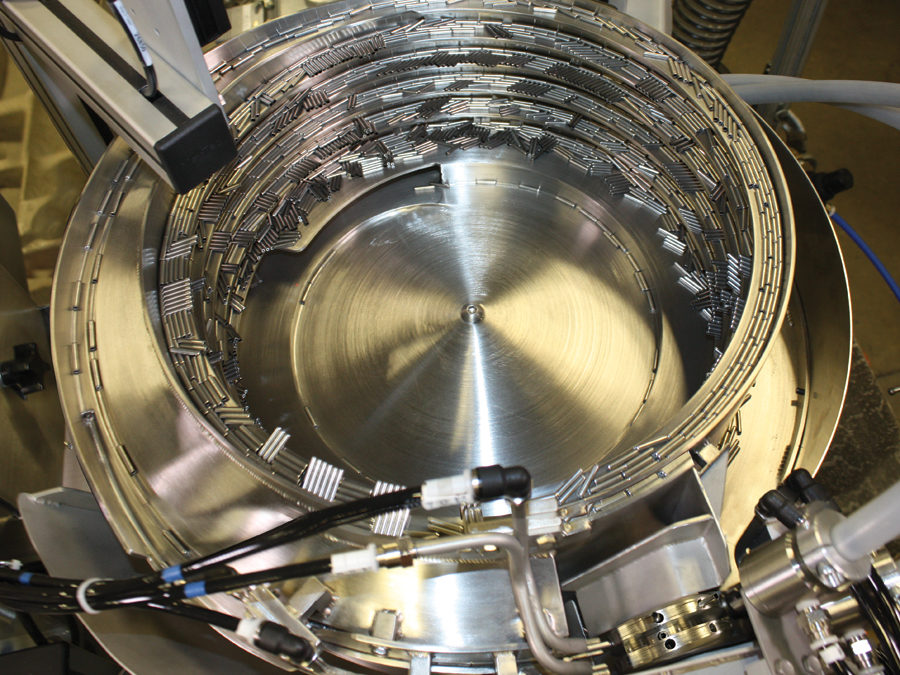

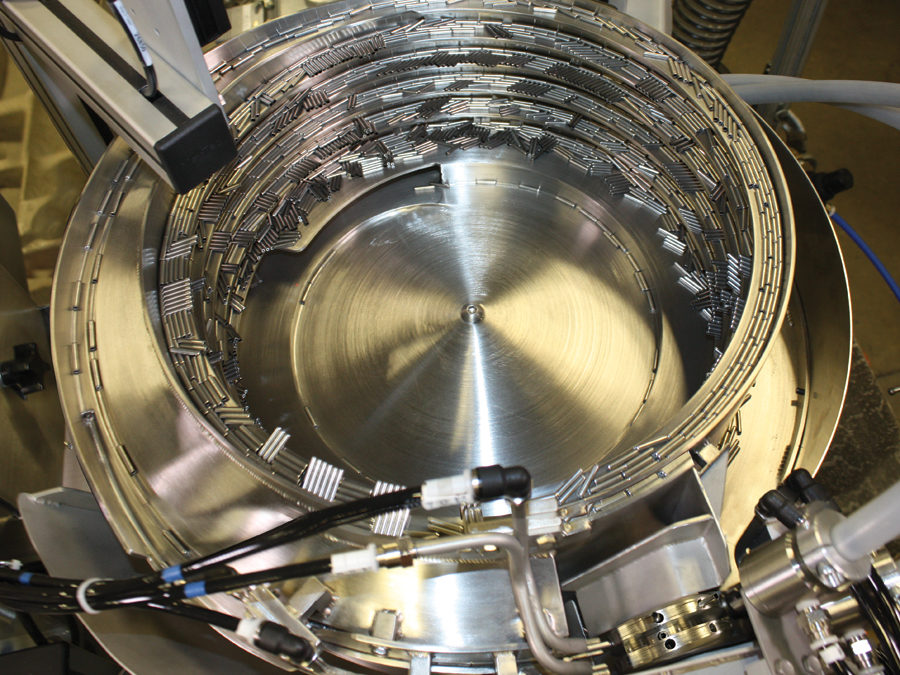

Problem: The manufacturer of critical control products was looking for a way to feed bulk pins to an assembly robot. The pins were small and, other than large and small openings at opposite ends, had no other distinguishing features. It was critical that the pins be...

by Kevin Yaney | Nov 22, 2019 | Escapements and Mechanisms

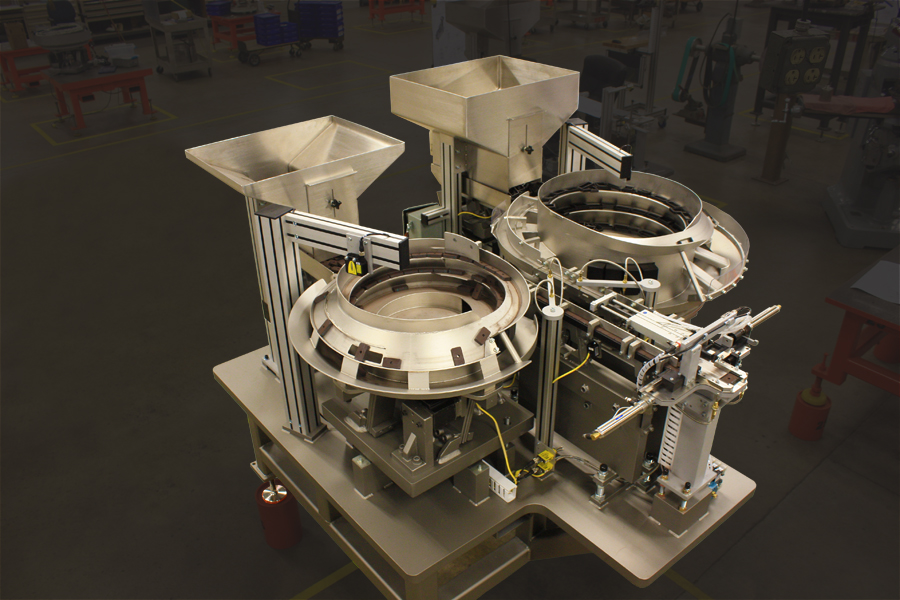

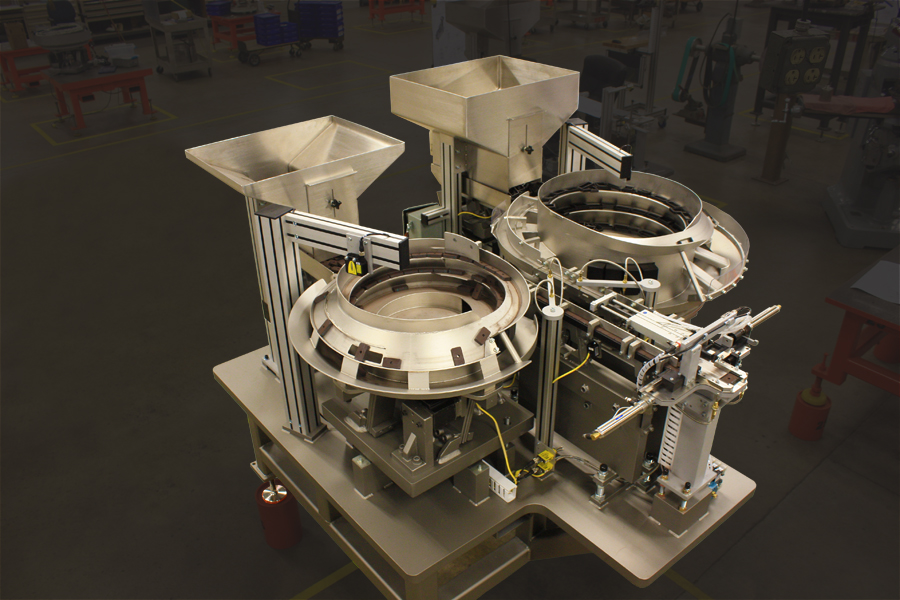

Problem: A lawnmower manufacturer needed to update a parts feeder on their assembly line. The equipment fed two components of a magneto to a robot. The two parts needed to be assembled, with a magnet placed inside a plastic holder before the robot picked it up....

by Fortville Feeders | Jun 26, 2019 | Escapements and Mechanisms, Feeder Bowls

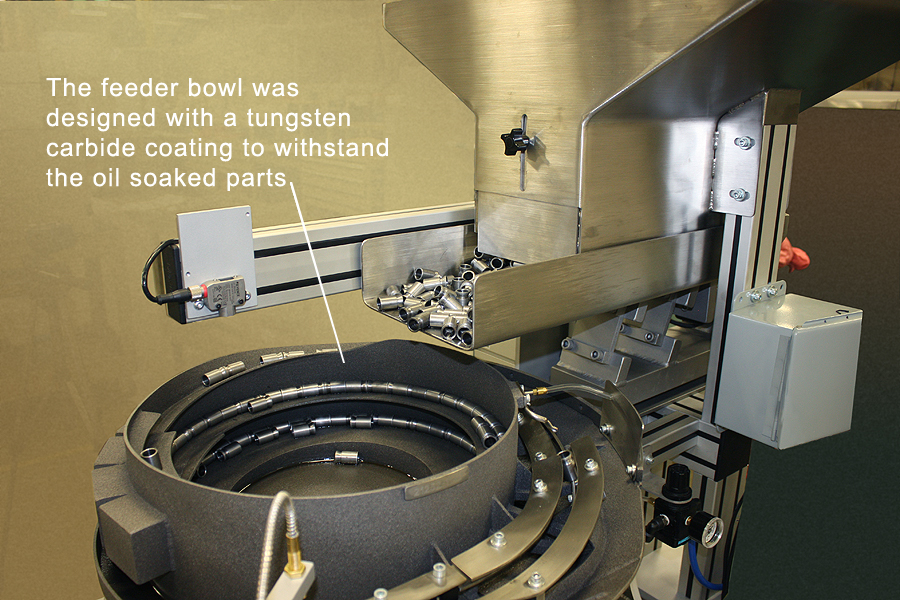

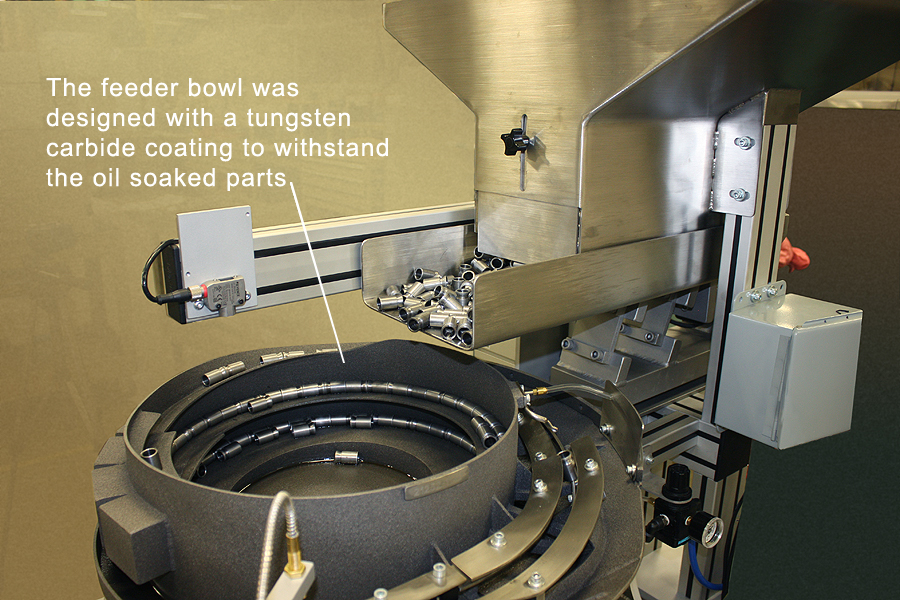

Problem: The customer needed to have a flux sleeve steel part oriented and isolated for robotic arm pick up. The problem: the parts were required to be drenched in oil prior to pick up. Oily parts are not only messy, they have a tendency to stick together or...

by Fortville Feeders | Jun 26, 2019 | Escapements and Mechanisms

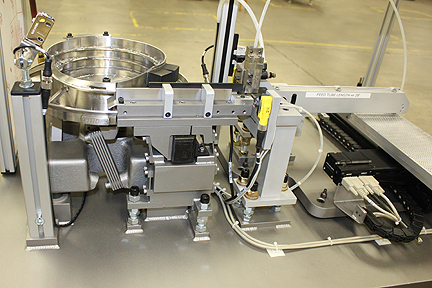

Problem: The customer was hand loading very small pins into a tray, with a matrix of pockets, for robotic pick up. Each tray held 1,380 pins. This was a tedious and time consuming process. The customer was seeking an automation solution to present the pins for...

by Fortville Feeders | Jun 26, 2019 | Escapements and Mechanisms

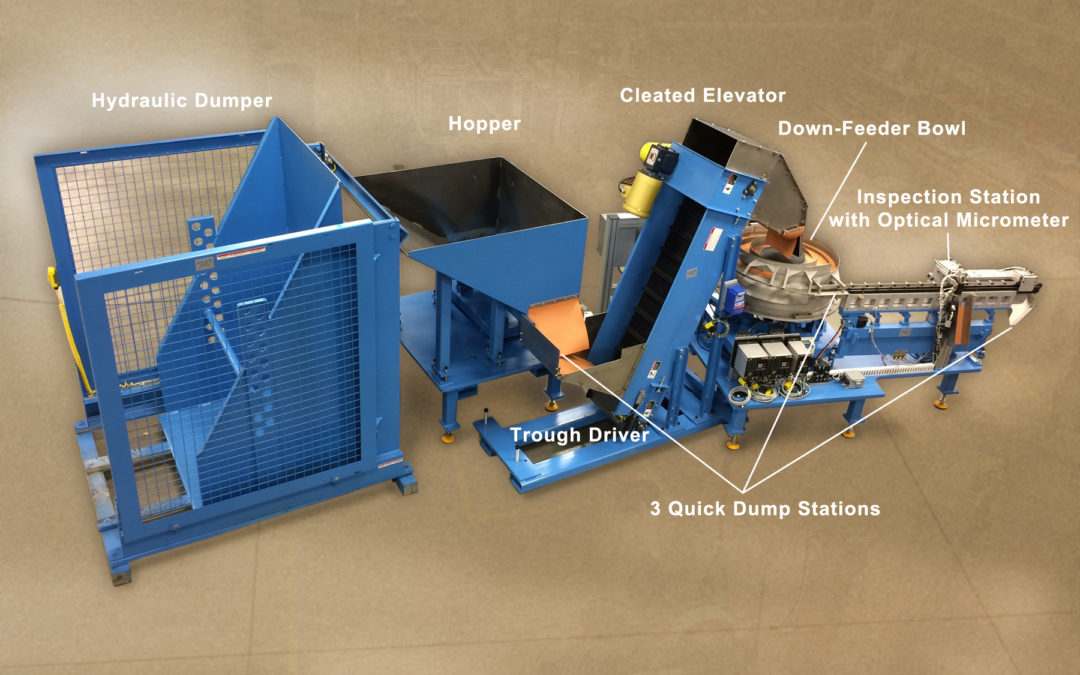

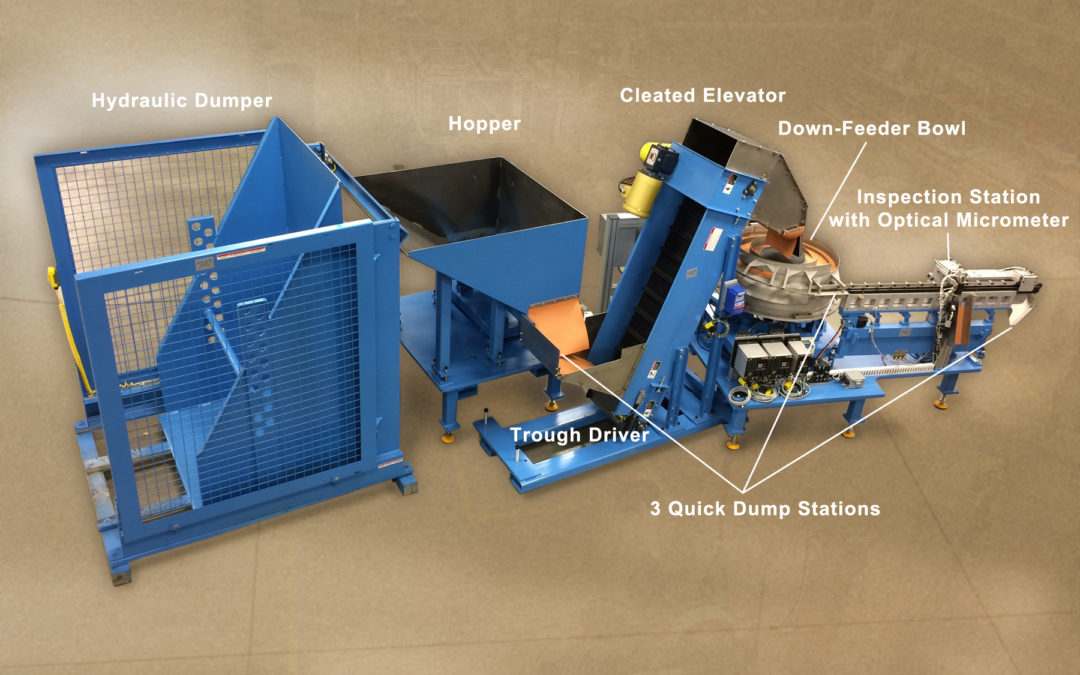

Problem The customer needed a way to feed large bolts of varying lengths to its heavy duty wheel hub assembly cell. They manufacture eight different axle assemblies, each with a different size wheel bolt. They needed a feeder system that could handle all eight...

by Fortville Feeders | Jun 26, 2019 | Escapements and Mechanisms

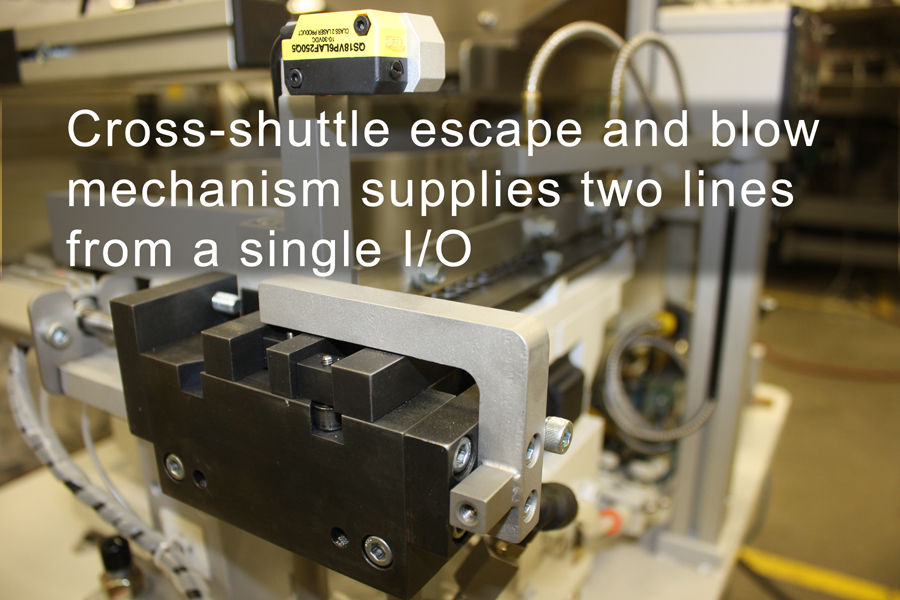

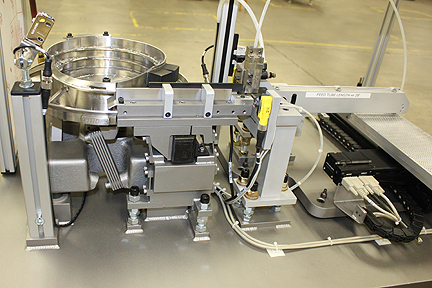

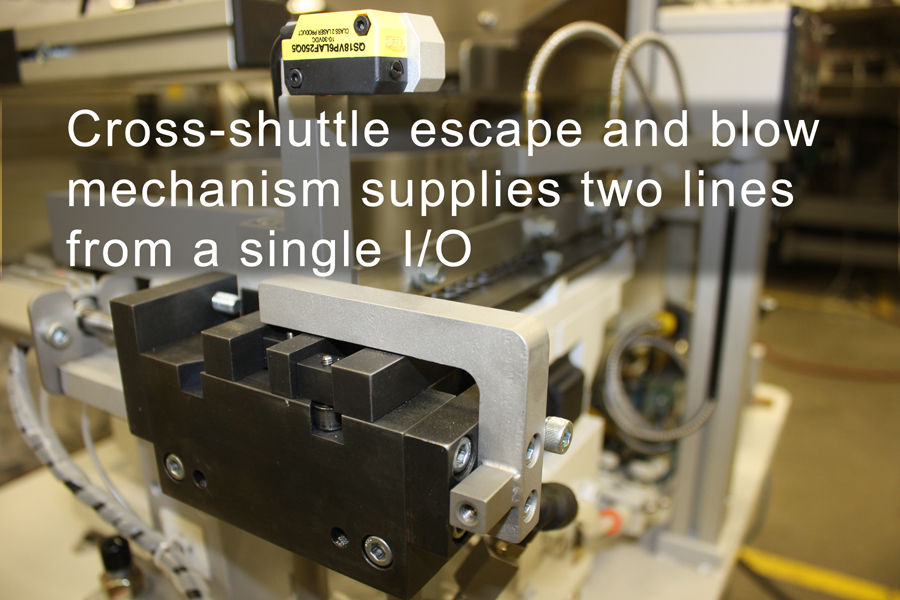

Problem The customer is a manufacturer of small gasoline engines used in lawn and garden implements. They had a feeder system that moved very small bolts to two staging locations. The system used a single feeder bowl and an escape and blow device with a diverter that...

Recent Comments