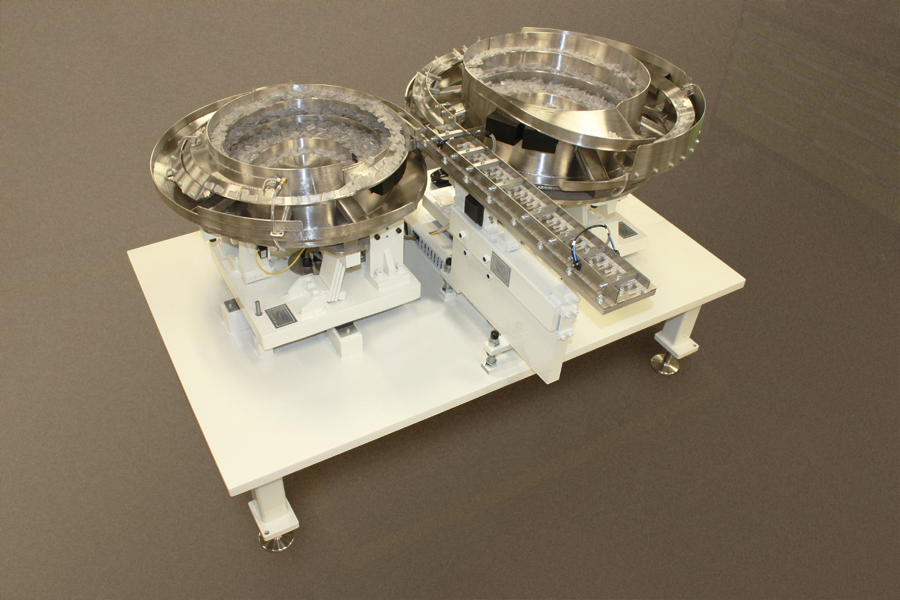

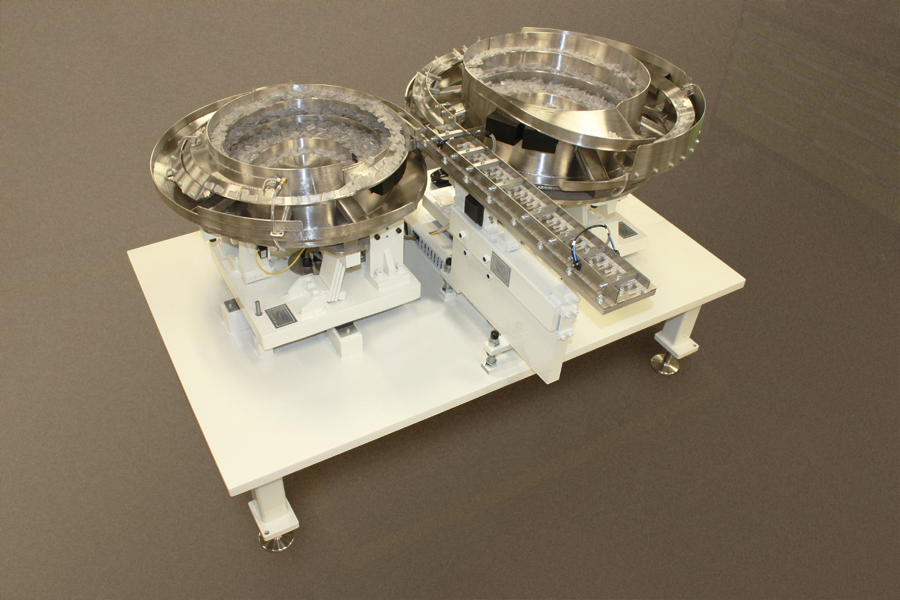

by Fortville Feeders | Oct 14, 2021 | Featured, Tracking Systems, Uncategorized

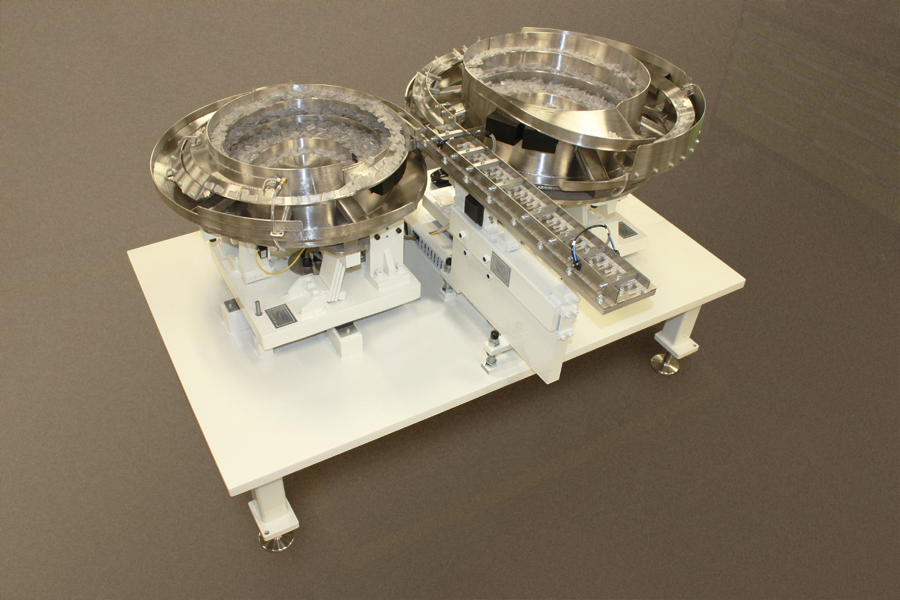

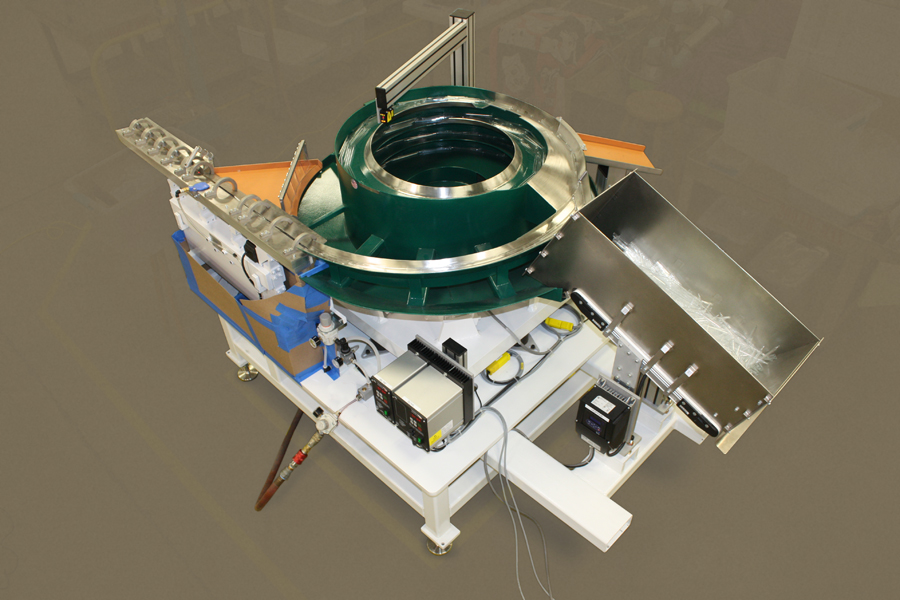

Problem: A medical device manufacturer needed to replace an inefficient feeder system for two caps. The system they had attempted to feed two parts from the same vibratory bowl. The two caps had very different geometries. It caused constant jams in their old feeder....

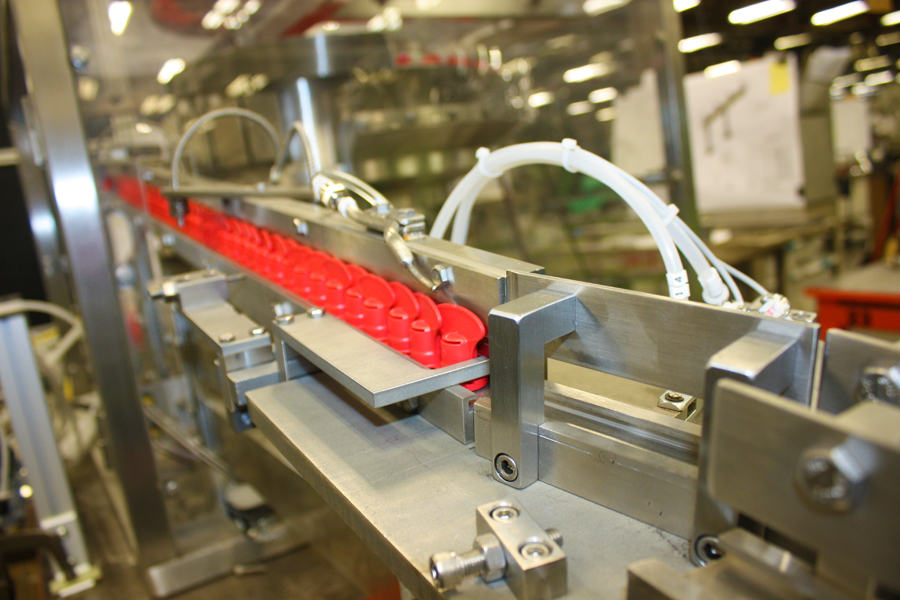

by Fortville Feeders | Aug 2, 2021 | Featured, Tracking Systems

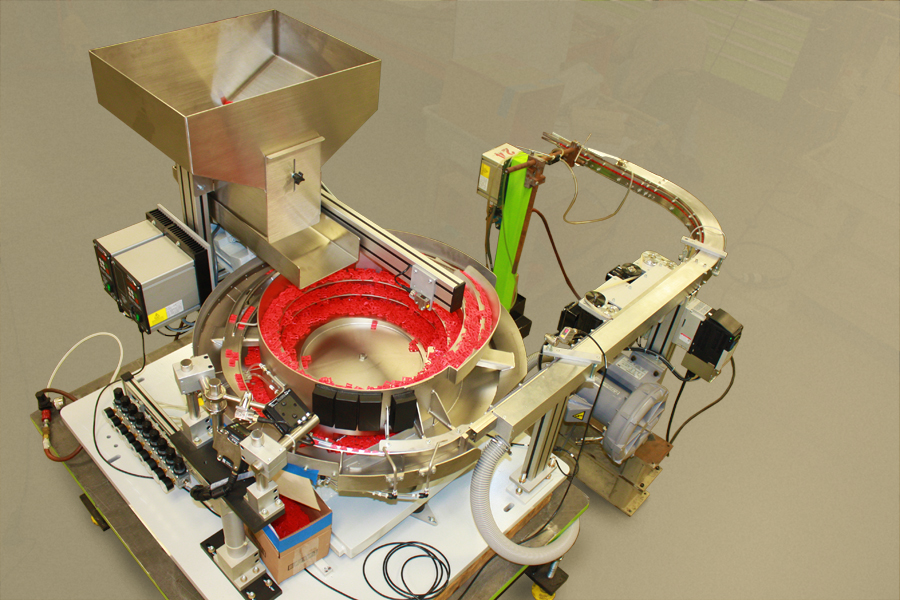

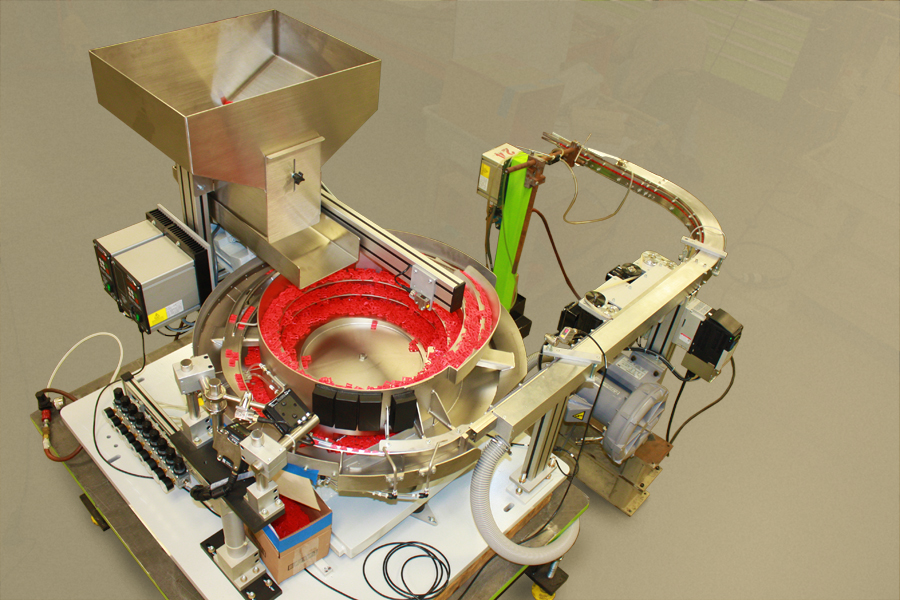

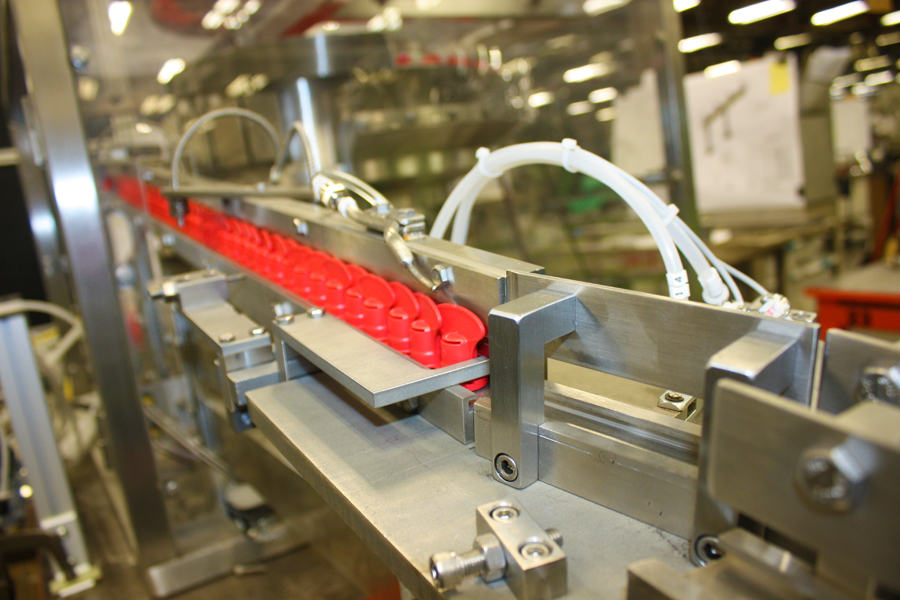

Problem: The manufacturer of plastic containers was in need of an automated feeder system for their closure components. They needed a high-speed system that would handle the molded plastic parts without clogging the machine while supplying their assembly lines at 200...

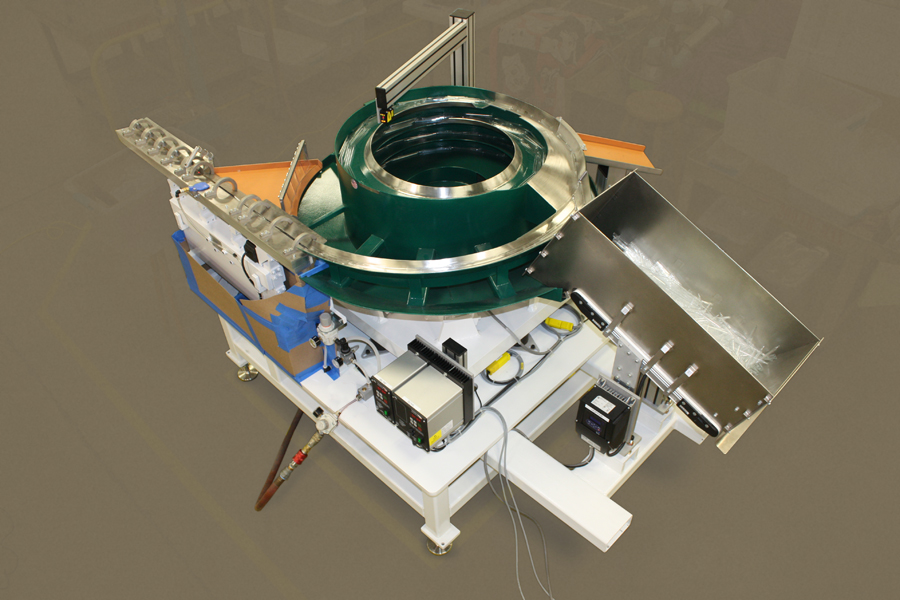

by Fortville Feeders | Jun 18, 2021 | Escapements and Mechanisms, Featured

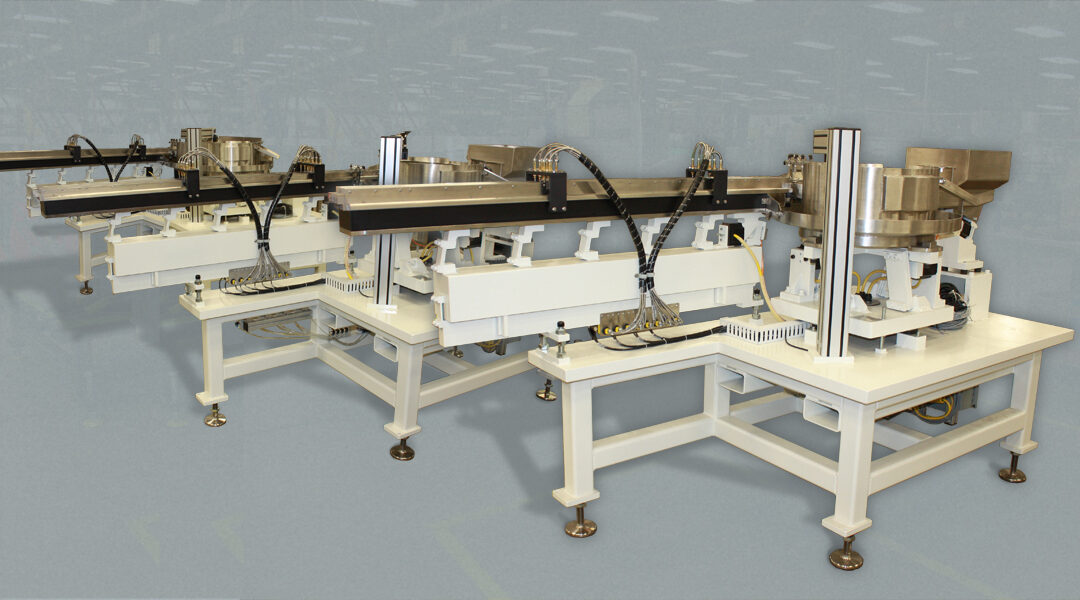

Problem: A manufacturer of hand-held outdoor equipment was in need of an automated parts feeding system that would lift bushing collars to three transfer stations on their assembly line. The three stations needed to operate independently of the other lines and supply...

by Fortville Feeders | May 17, 2021 | Featured, Tracking Systems

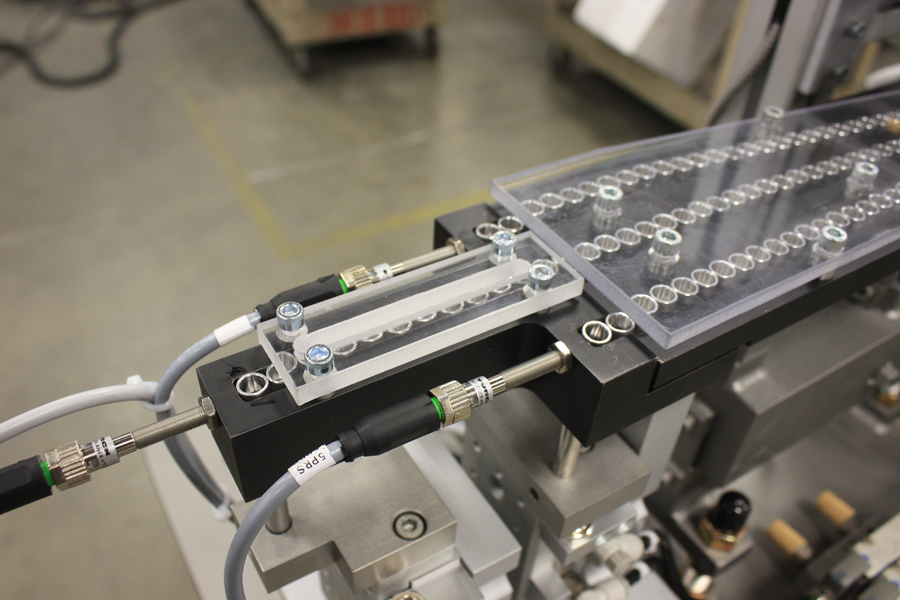

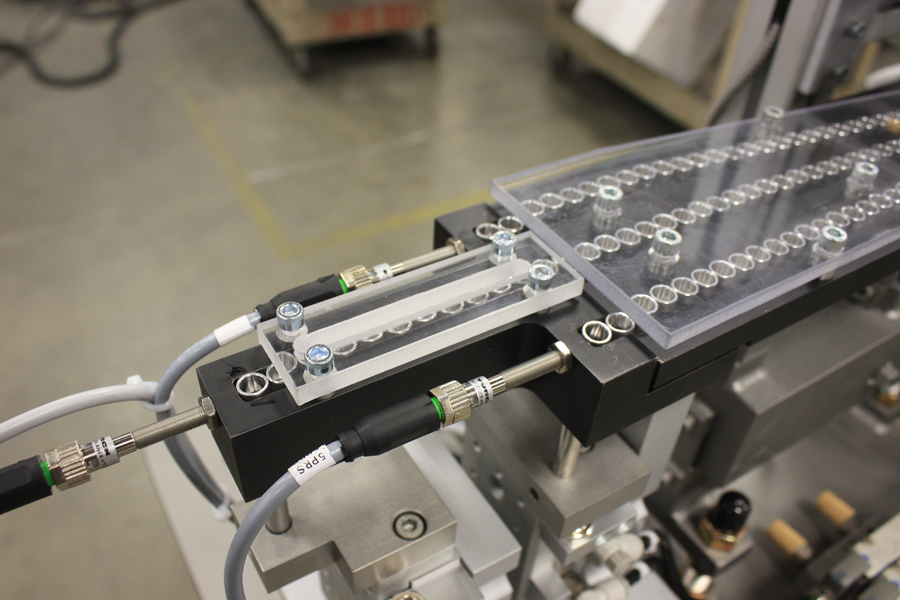

Problem: An automated machine builder that specialized in medical syringe assembly and packaging was in need of three identical feeder machines to handle needle holders. The parts were lightweight, very small (1 mm and 3mm widths) and needed to be fed at a rate of 54...

by Kevin Yaney | Mar 25, 2021 | Featured, Tracking Systems

Problem: An integrator was building an automated system that packaged five different sizes of medical glass pipettes. The pipettes were very fragile and had to be gently handled, but delivered at 80 parts per minute. This included bulk loading of the parts, moving...

by Fortville Feeders | Mar 4, 2021 | Featured, Tracking Systems

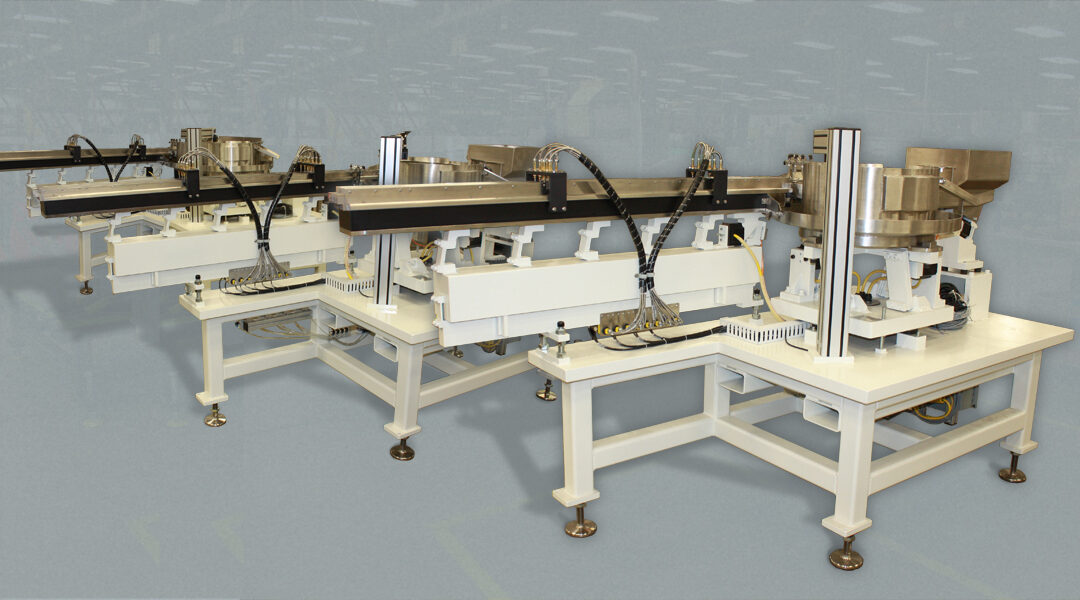

Problem: A medical liquids bottler had a capping machine that used a Fortville Feeders designed parts feeder. The bottler made some changes to their bottling automation and needed a system that fed two lines instead of one. They approached Fortville Feeders to...

Recent Comments