by Kevin Yaney | Jan 24, 2020 | Featured, Feeder Bowls

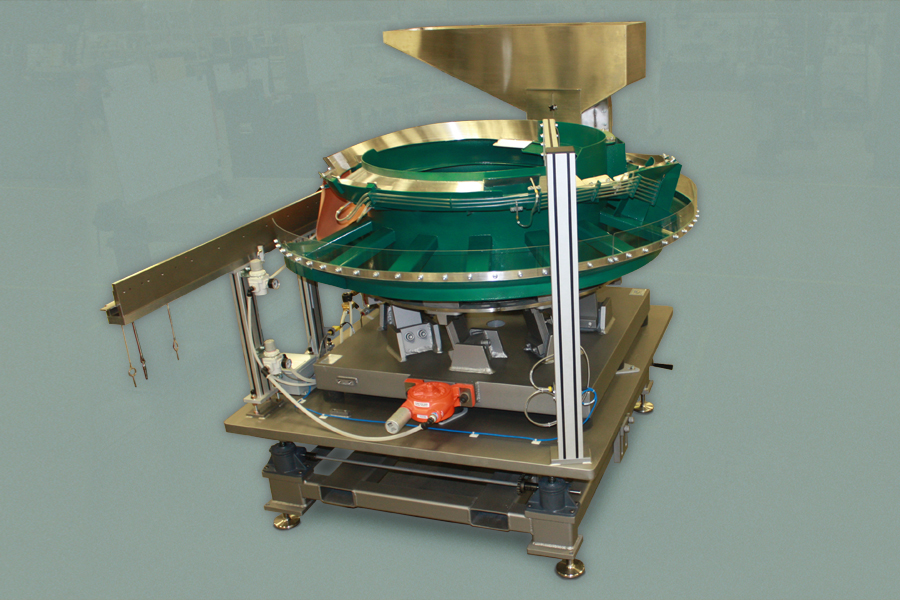

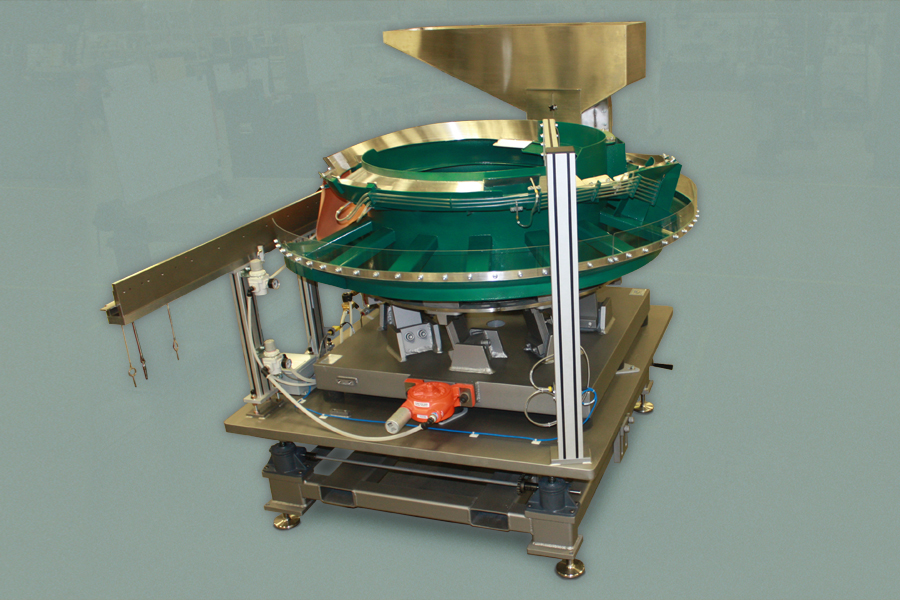

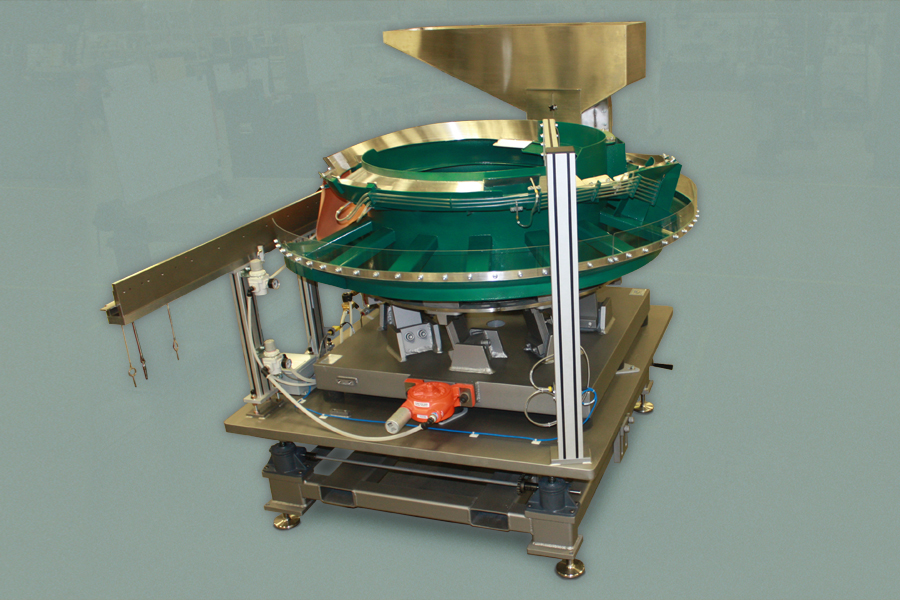

Problem: The customer was bottling highly combustible consumer products in aerosol cans. They needed an automated feeder system to handle five different caps for these cans. The feeder had to orient and move the parts at a high speed, but more importantly, it had to...

by Kevin Yaney | Nov 5, 2019 | Feeder Bowls, Tracking Systems

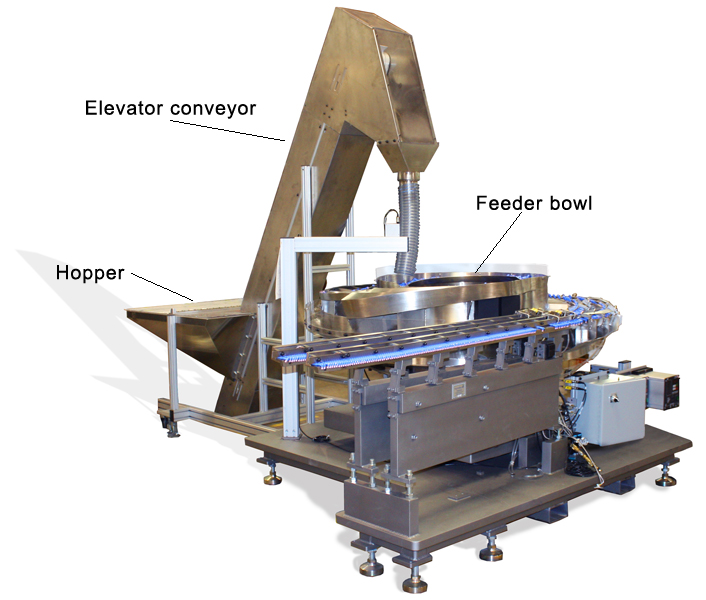

Problem: The manufacturer of water treatment control valves was looking for a way to automate their parts feeding and loading system that would continuously feed five conveyors that supplied their assembly station. The loading had previously been done by hand. The...

by Fortville Feeders | Jun 27, 2019 | Feeder Bowls

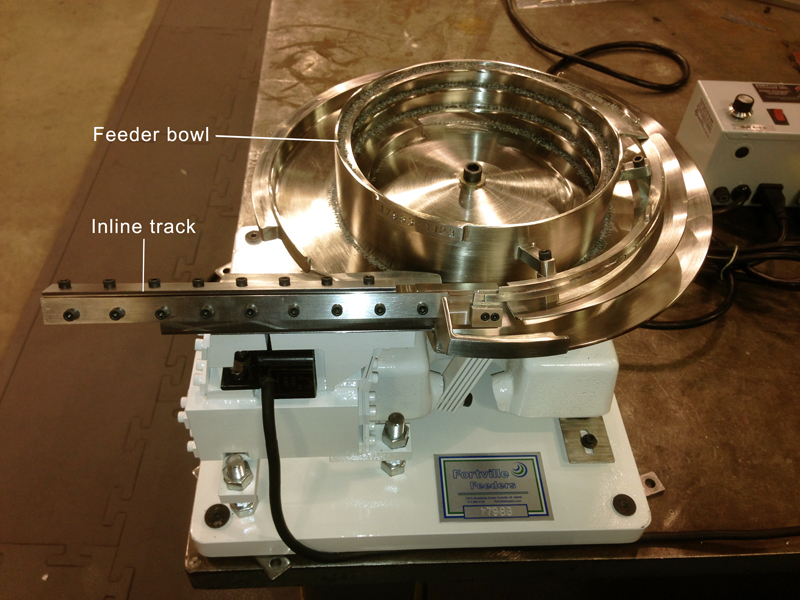

Problem: The customer was in need of a feeder system for delicate ceramic parts. The system had to move the parts without scratching or damaging them. Solution: Fortville designed a bulk hopper and vibratory feed system all overlaid with a Surlyn coating. A...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls, Tracking Systems

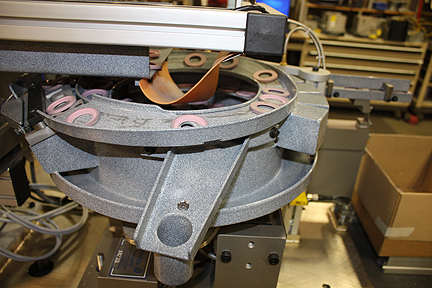

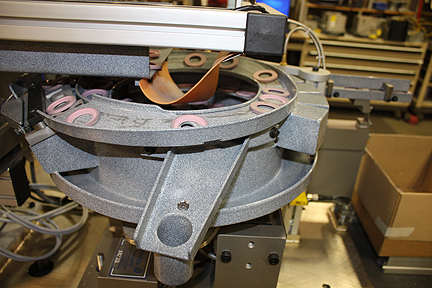

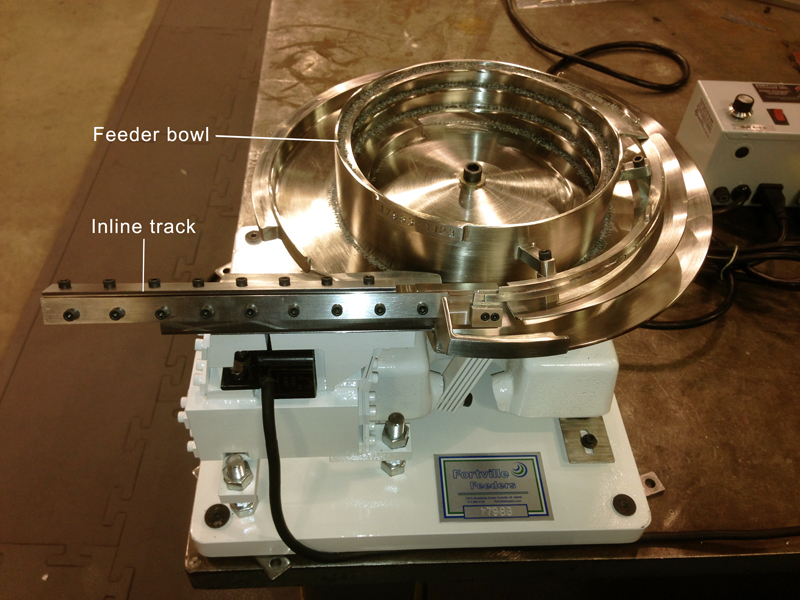

Problem: The customer needed to sort and orient small wire parts (.150″ squares made with .0085″ wire) for high speed automation. They needed a system that would feed and track the parts reliably. Solution: With any small part, positioning in correct...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls, Tracking Systems

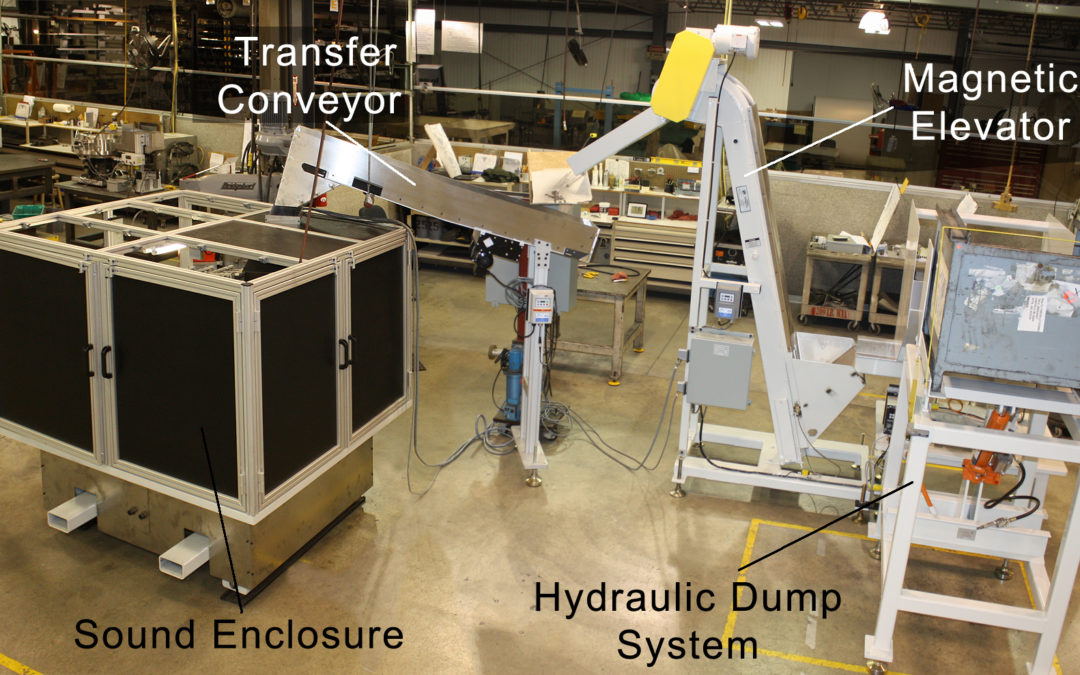

Problem: The customer was packaging prophy angles that are used in dentists offices for teeth cleaning. They wanted a feeder system that would run a dual line for their bagging systems. Each line would be required to feed up to 200 parts per minute....

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls, Tracking Systems

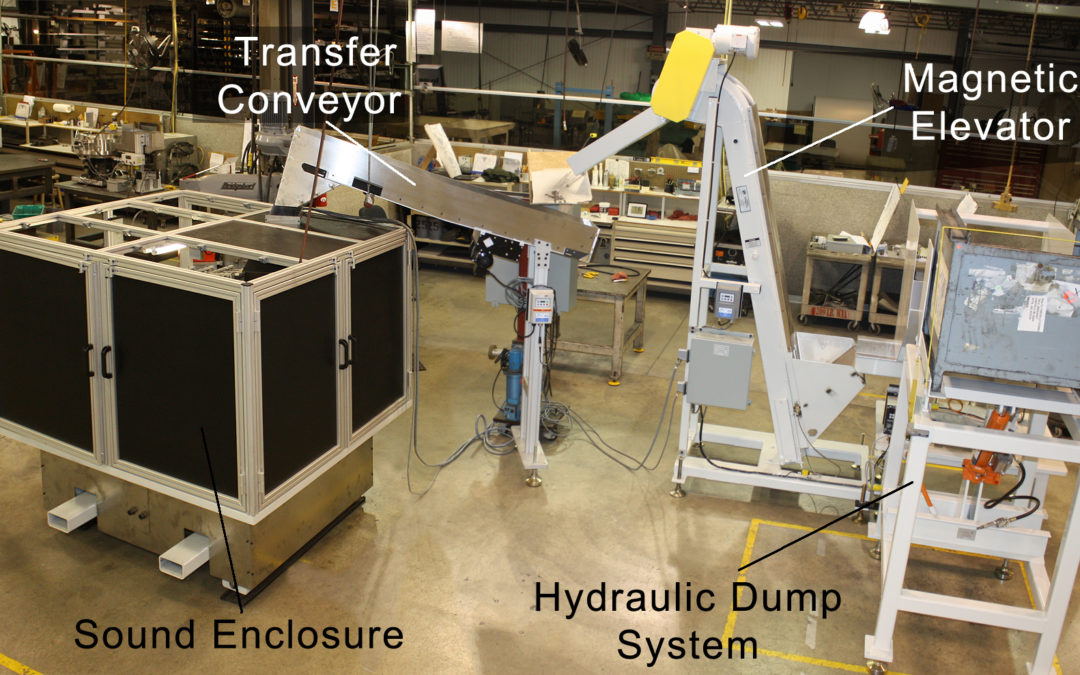

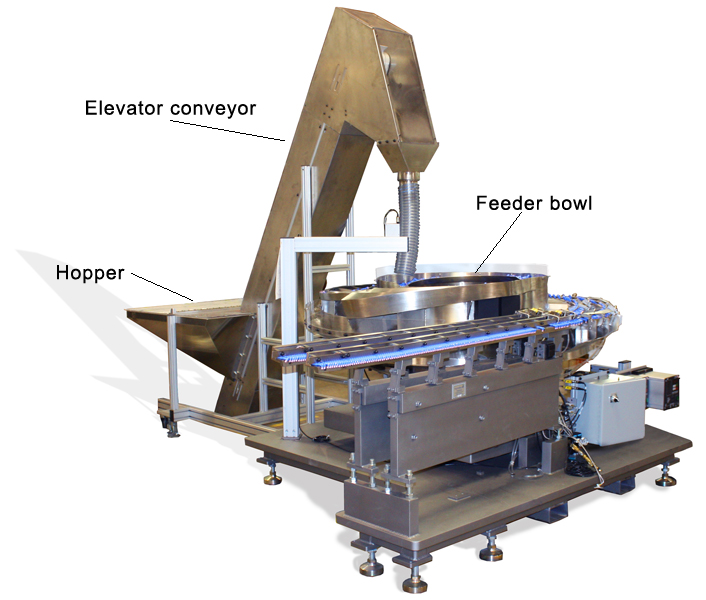

Problem: The customer had a need to feed a four line grinding machine with a continuous feed of parts. They had a bulk parts tote for their parts and a washing system, but needed to automate the loading and sorting process from start to finish....

Recent Comments