by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: The customer was working with two different sizes of braze beads that they wanted to sort and feed down an automated line. Solution: Fortville built a bulk hopper that fed the beads into a vibratory feeder bowl. This allowed the operator to...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: The customer was dealing with very thin metal parts that would often misfeed in their automated system. They needed a way to supply the parts in an accumulative fashion (edge to edge) without overlapping. Solution: Fortville designed a vibratory...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: The customer needed to present thin steel blades down an assembly line in a specific orientation. However, the parts were essentially symmetrical, with the exception of a small notch which needed to be presented on the right side. With no real...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem The customer needed a way to feed large bolts of varying lengths to its heavy duty wheel hub assembly cell. They manufacture eight different axle assemblies, each with a different size wheel bolt. They needed a feeder system that could handle all eight...

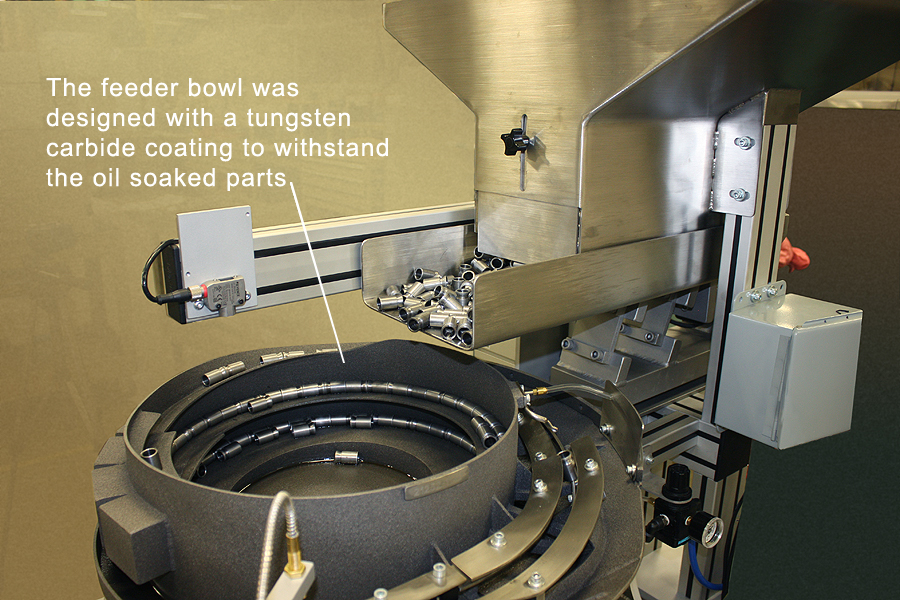

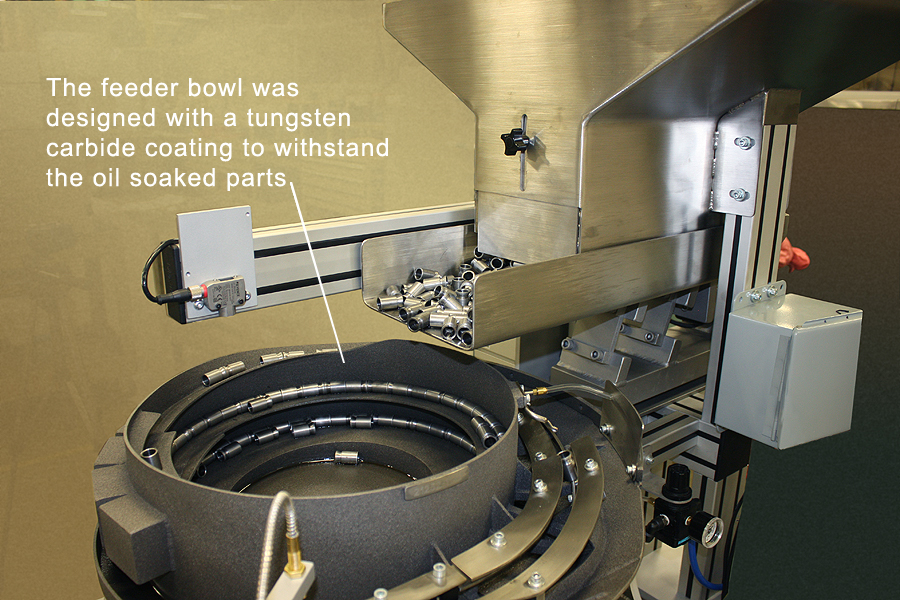

by Fortville Feeders | Jun 26, 2019 | Escapements and Mechanisms, Feeder Bowls

Problem: The customer needed to have a flux sleeve steel part oriented and isolated for robotic arm pick up. The problem: the parts were required to be drenched in oil prior to pick up. Oily parts are not only messy, they have a tendency to stick together or...

by Fortville Feeders | Jun 26, 2019 | Feeder Bowls

Problem: A manufacturer of toothbrushes had six different styles of toothbrushes, each with an ergonomic handle with soft rubber finger grips. They were looking for a feeder system that would sort, orient, and move the product to their laser etching and packaging...

Recent Comments