by Kevin Yaney | Mar 25, 2021 | Featured, Tracking Systems

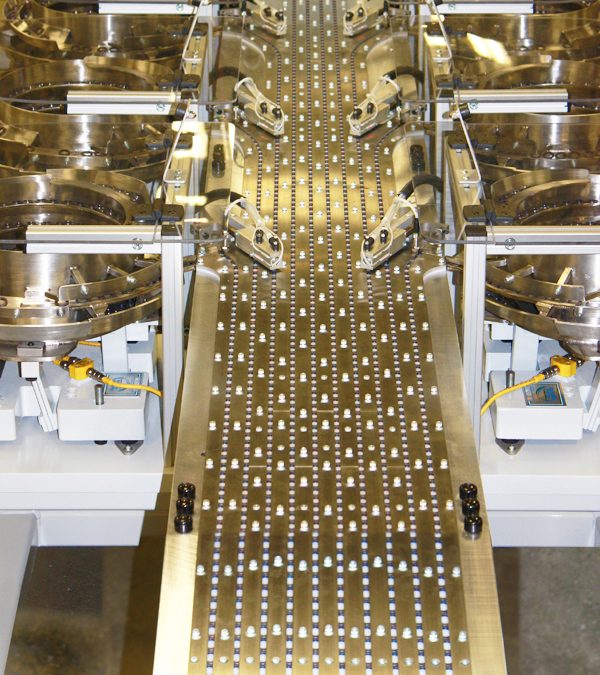

Problem: An integrator was building an automated system that packaged five different sizes of medical glass pipettes. The pipettes were very fragile and had to be gently handled, but delivered at 80 parts per minute. This included bulk loading of the parts, moving...

by Fortville Feeders | Mar 4, 2021 | Featured, Tracking Systems

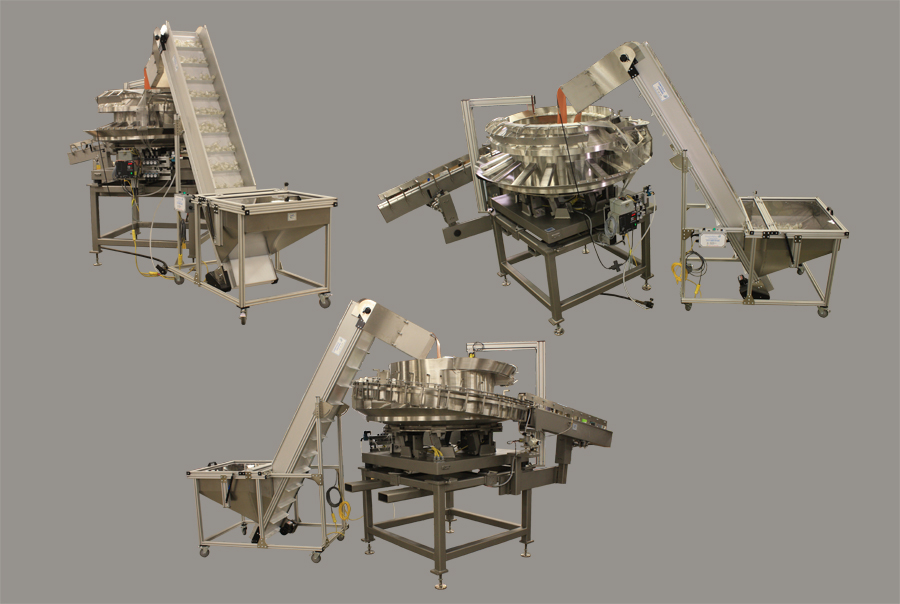

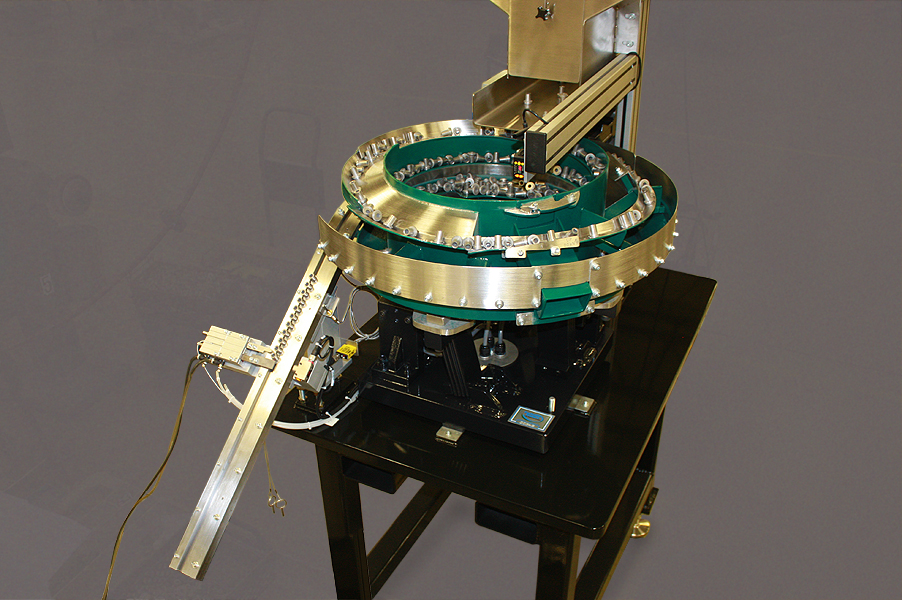

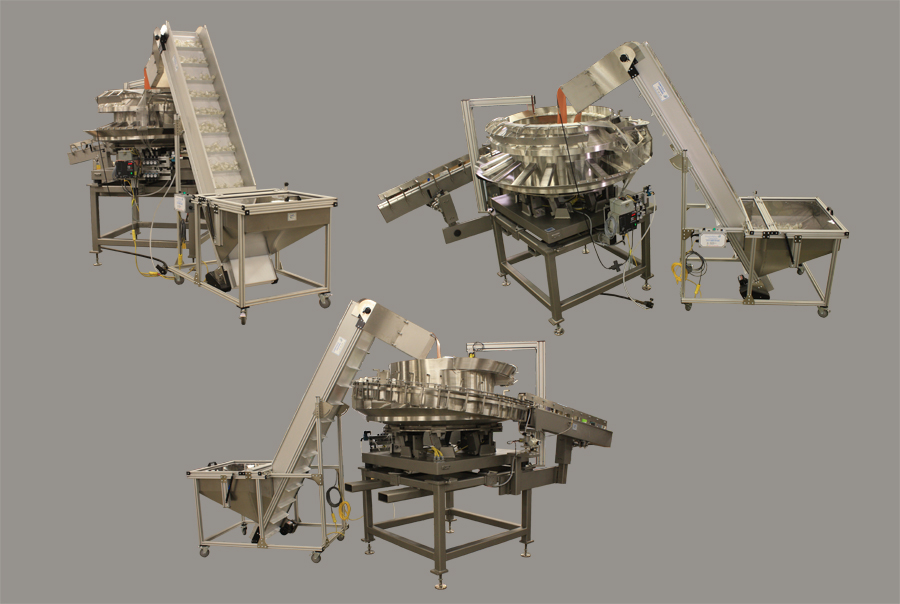

Problem: A medical liquids bottler had a capping machine that used a Fortville Feeders designed parts feeder. The bottler made some changes to their bottling automation and needed a system that fed two lines instead of one. They approached Fortville Feeders to...

by Fortville Feeders | Nov 13, 2020 | Featured, Tracking Systems

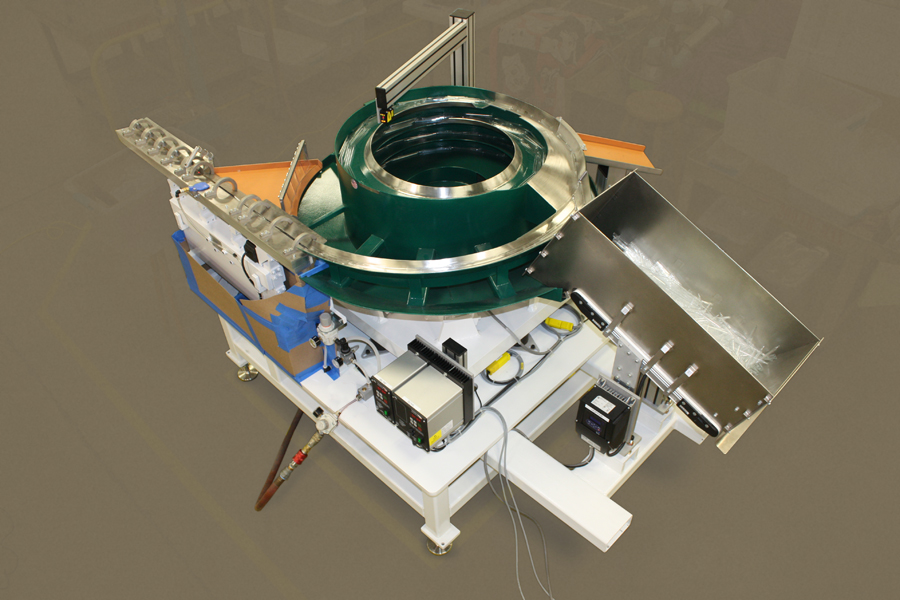

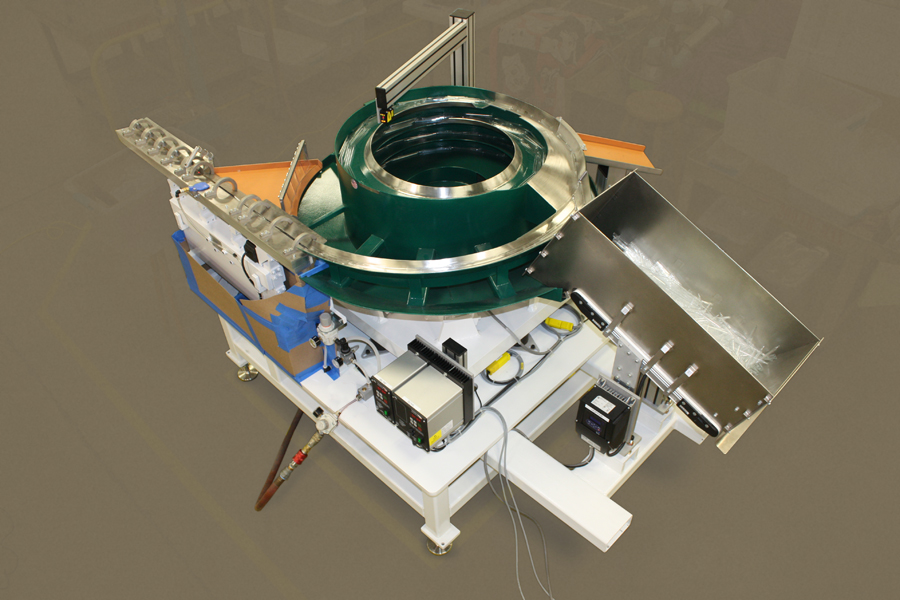

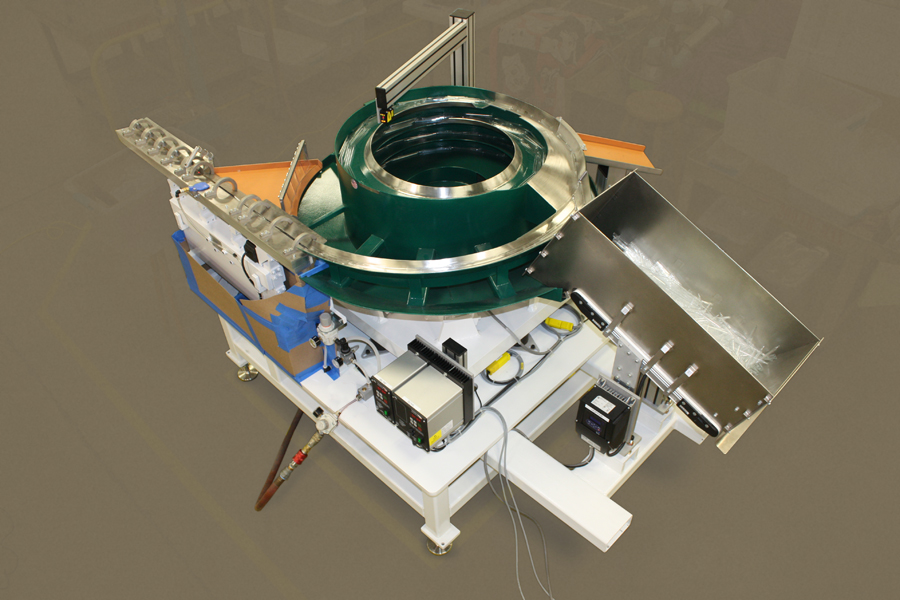

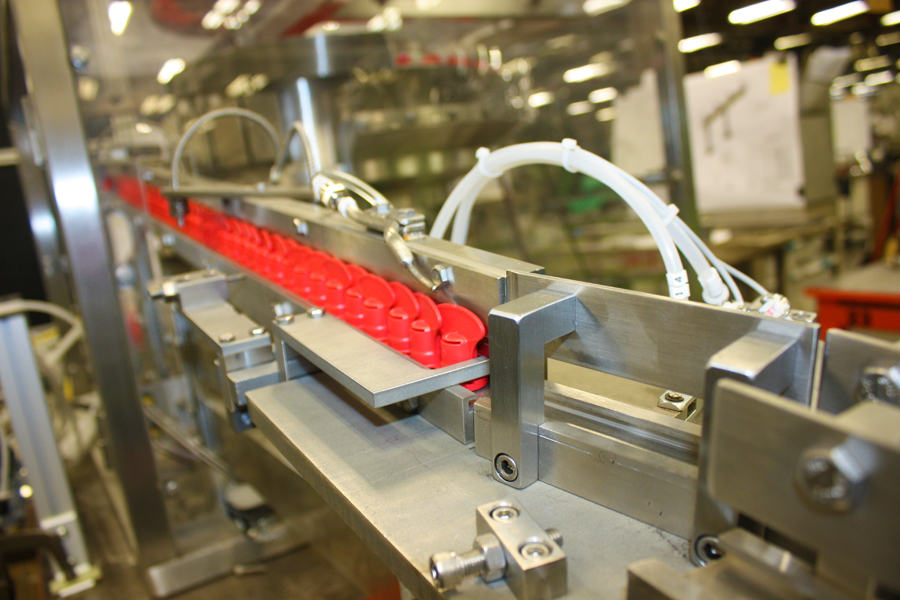

Problem: The manufacturer of hand sanitizer bottles desired a single feeder system for multiple foaming pump nozzles for their automated bottling assembly station. They had five different pump nozzles that were of different sizes and geometries. Some of these pump...

by Kevin Yaney | Aug 25, 2020 | High Speed Feeder Bowls, Tracking Systems

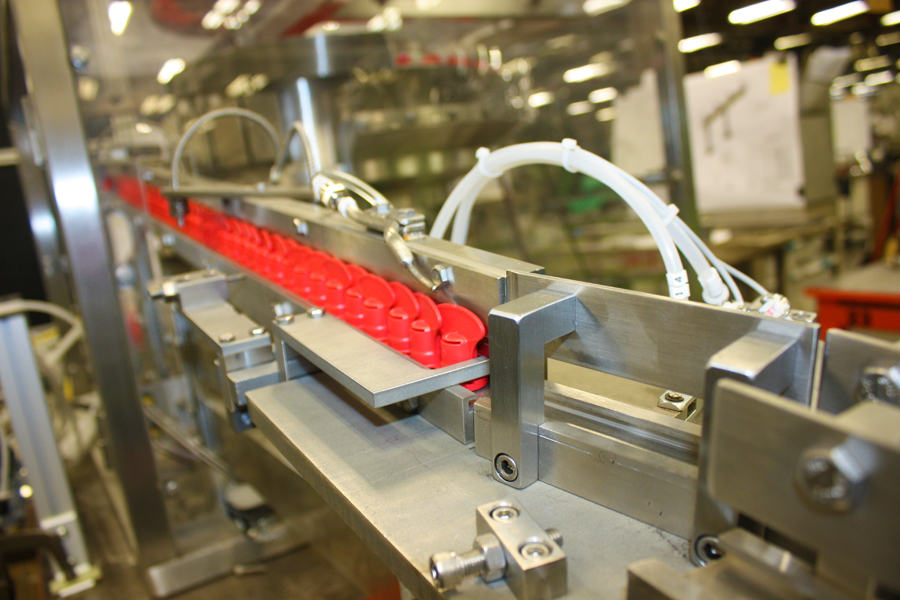

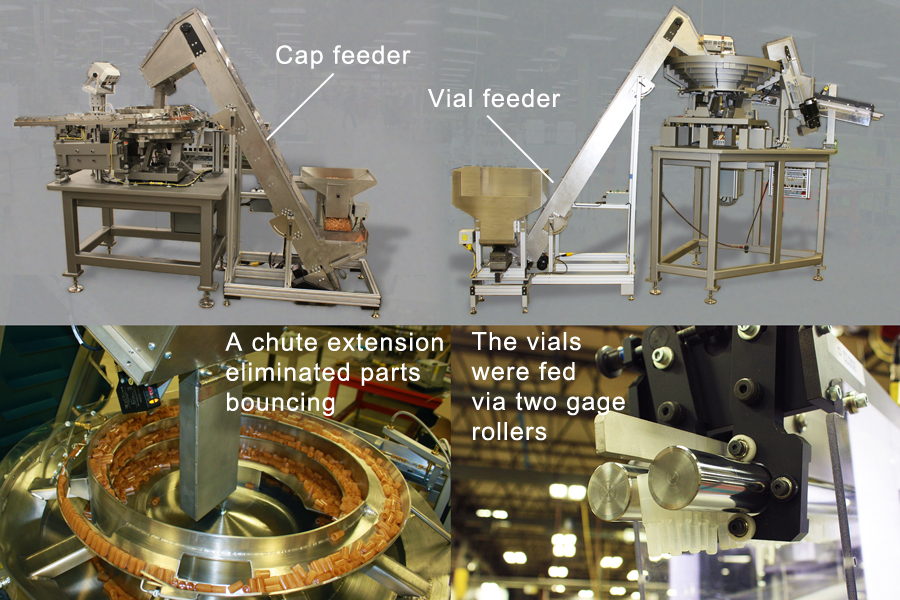

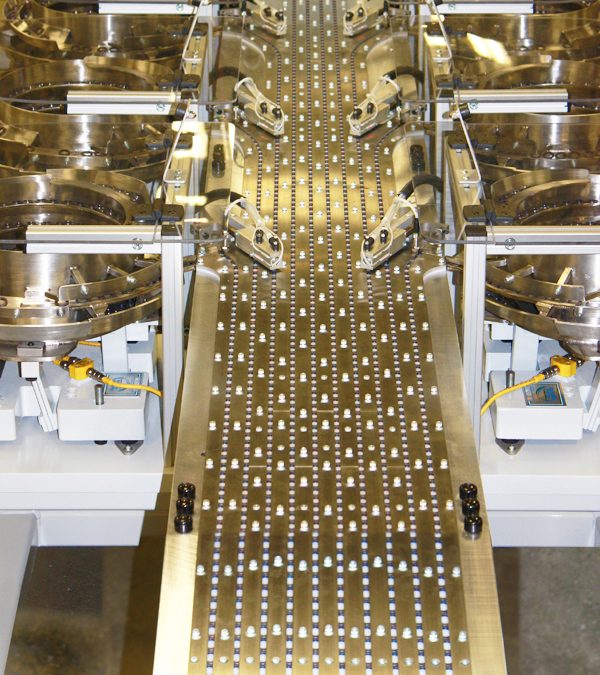

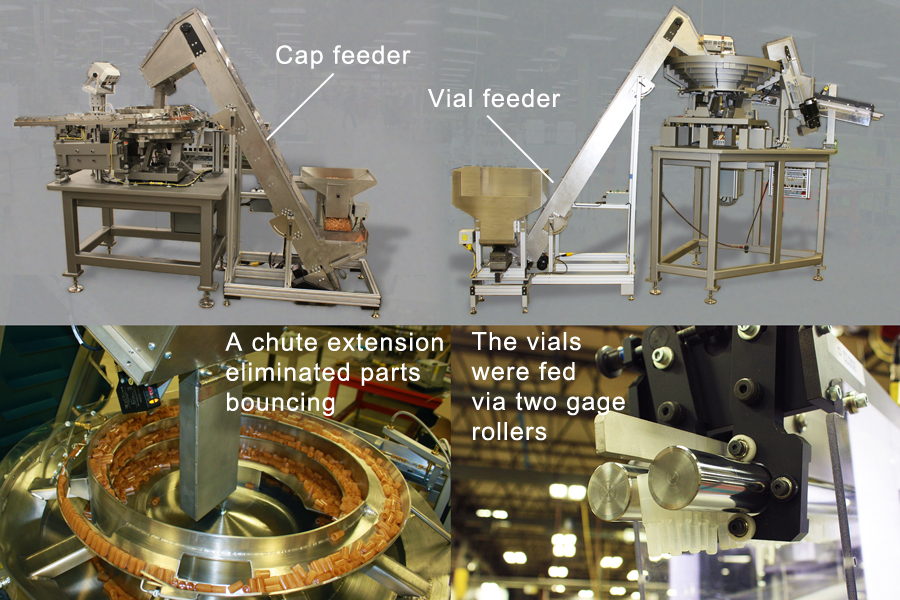

Problem: An integrator was building an assembly and labeling automation system for a medical packaging company. The high-speed system labeled vials and capped them before being filled. The customer needed two feeder systems; one for the vials and one for the caps,...

by Fortville Feeders | Aug 11, 2020 | Escapements and Mechanisms, Featured, Tracking Systems

Problem: A manufacturer needed a feed system to supply 10 spacers of various thicknesses to be used in the assembly of mechanical components. The spacers were picked and placed by robots that could be programmed to select any of the 10 spacers needed for the assembly....

by Fortville Feeders | Mar 12, 2020 | Tracking Systems

Problem: An integrator was building a parts resonance testing machine that checked powdered metal parts for defects. Powdered or sintered metal is prone to inclusions – cracks or pockets where air is trapped which weakens the structural integrity of the part....

Recent Comments