by Fortville Feeders | Jul 22, 2024 | Uncategorized

Problem: A medical parts manufacturer needed a parts feeder for the packaging of very small staples. Since this was a medical staple, the feeder system needed to meet cleanroom compliance standards. The part could not be handled during the feeding process and must be...

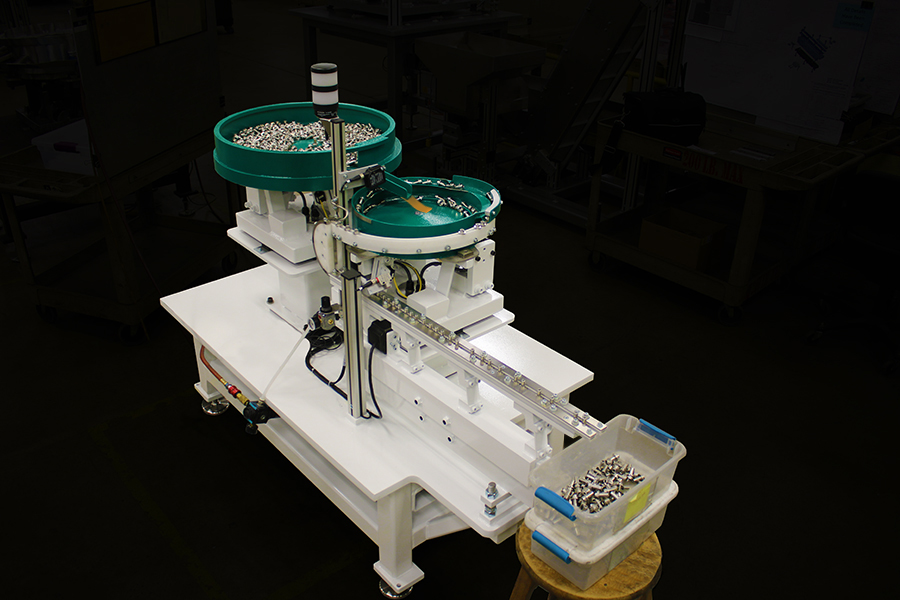

by Fortville Feeders | Jun 17, 2024 | Uncategorized

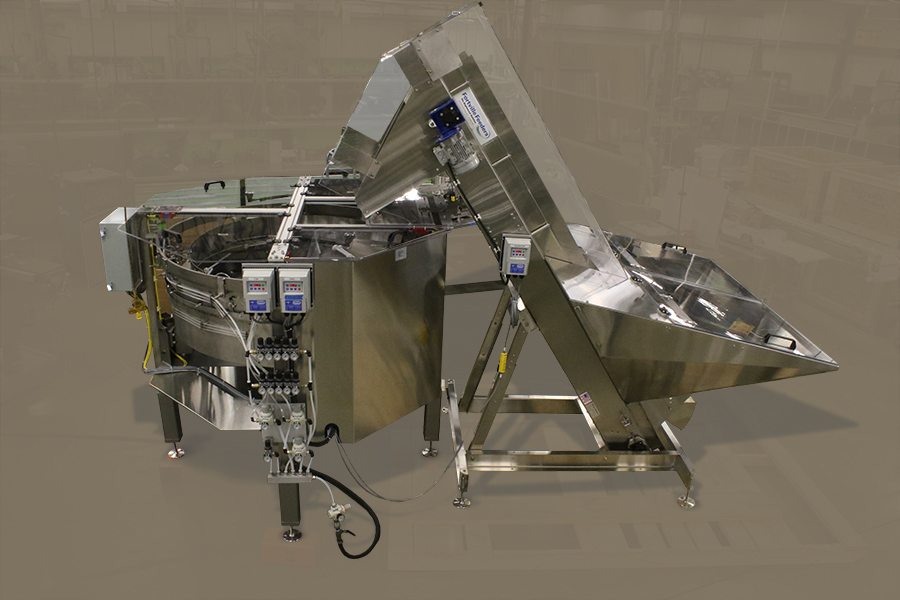

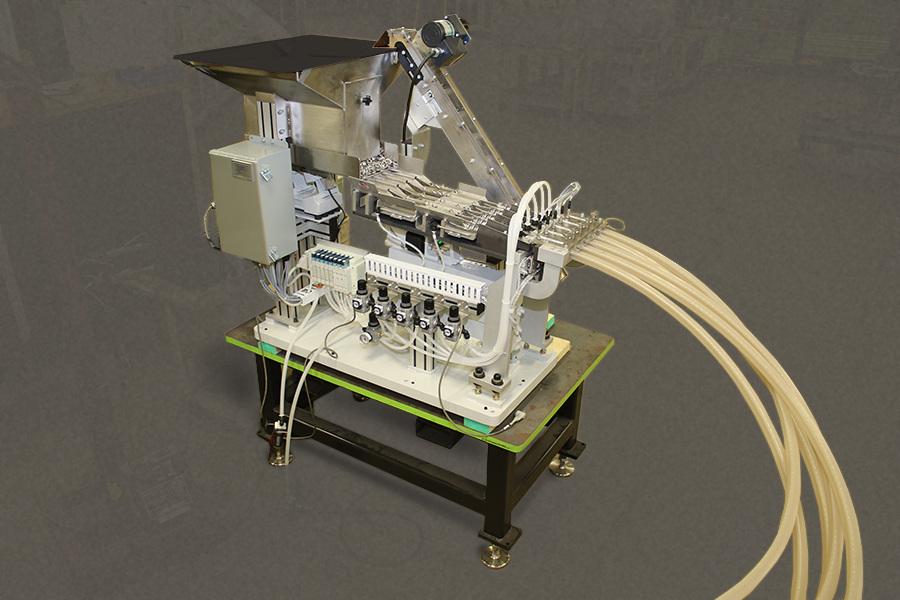

Problem: A truck manufacturer was looking for a rivet feeder that would feed an automated assembly cell. They needed 30 parts per minute delivered to their fastener robots. The customer had limited space for the feeder system. Everything had to fit into a small space....

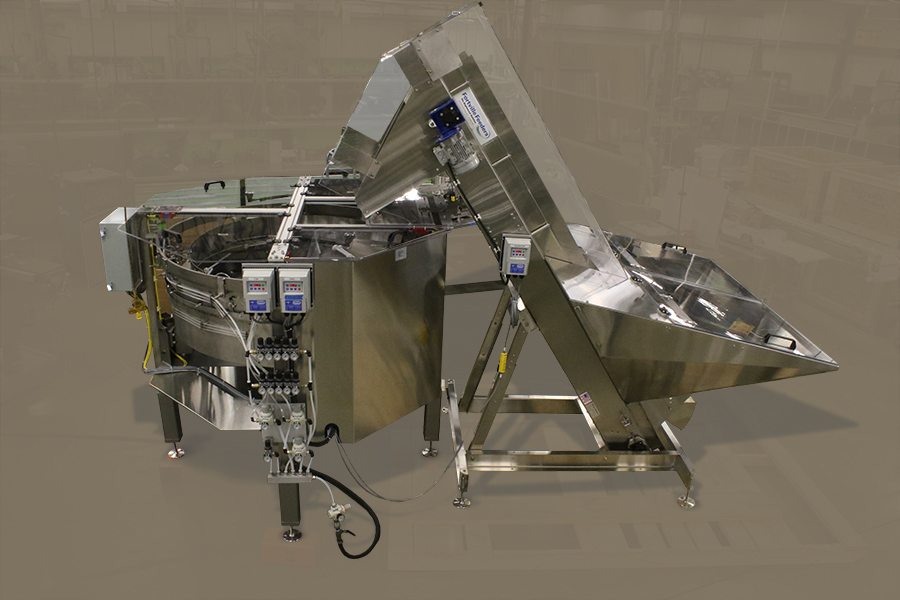

by Fortville Feeders | Aug 8, 2023 | Uncategorized

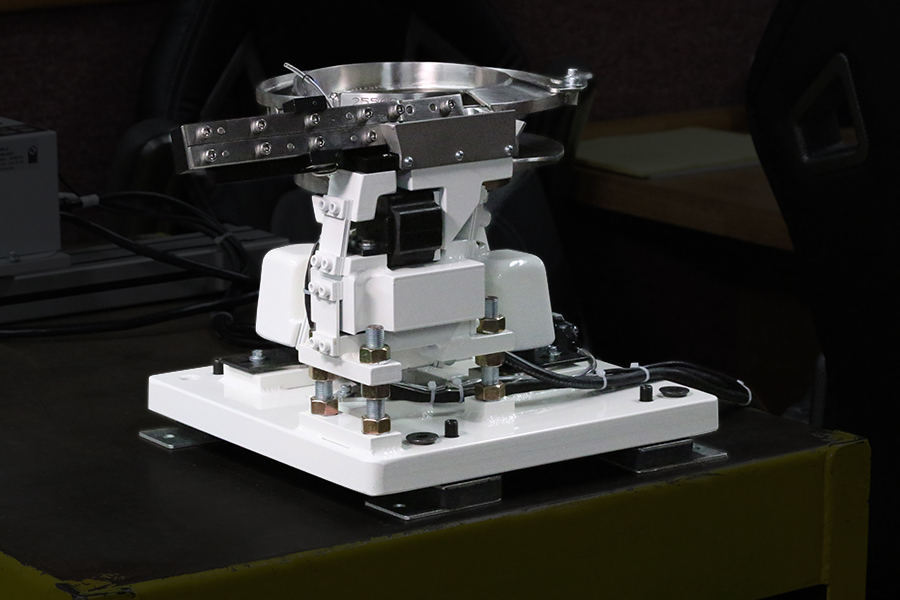

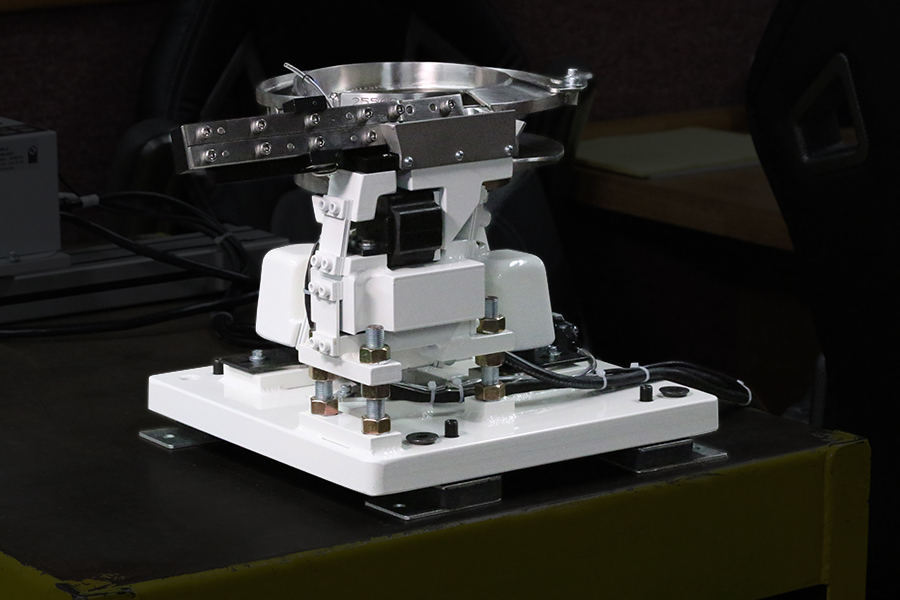

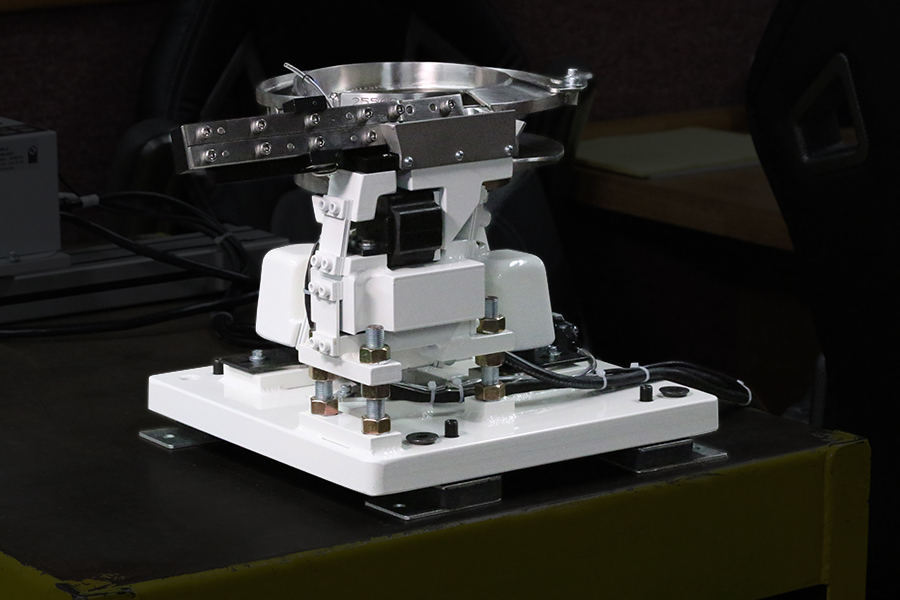

Problem: An integrator needed to feed sensitive metal parts to an inspection table without causing any mars or dings in the parts. The inspection table checked the quality of each part – taking bad parts off the line and sending good parts to the next phase of...

by Kevin Yaney | May 4, 2023 | Uncategorized

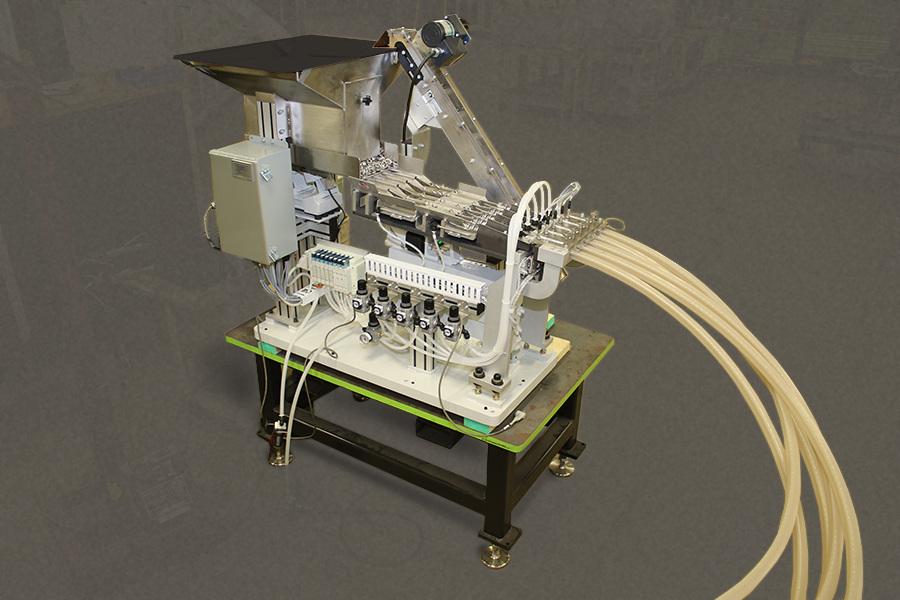

Problem: An integrator was in need of a high-speed parts feeder for a plastic pump and cap for a bottling assembly station. The customer had used a centrifugal feeder in the past and desired to have a duplicate machine built. In this case, the customer needed a system...

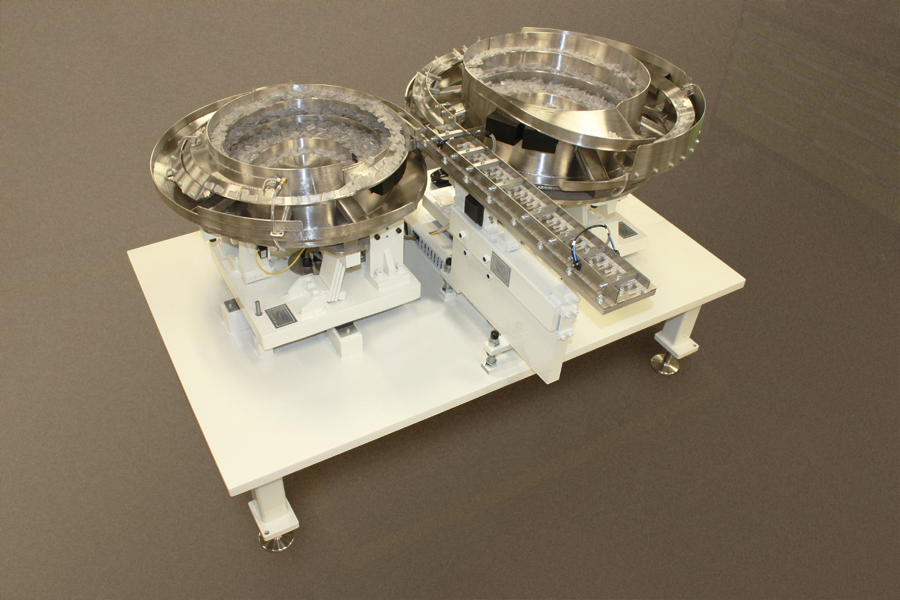

by Fortville Feeders | Oct 14, 2021 | Featured, Tracking Systems, Uncategorized

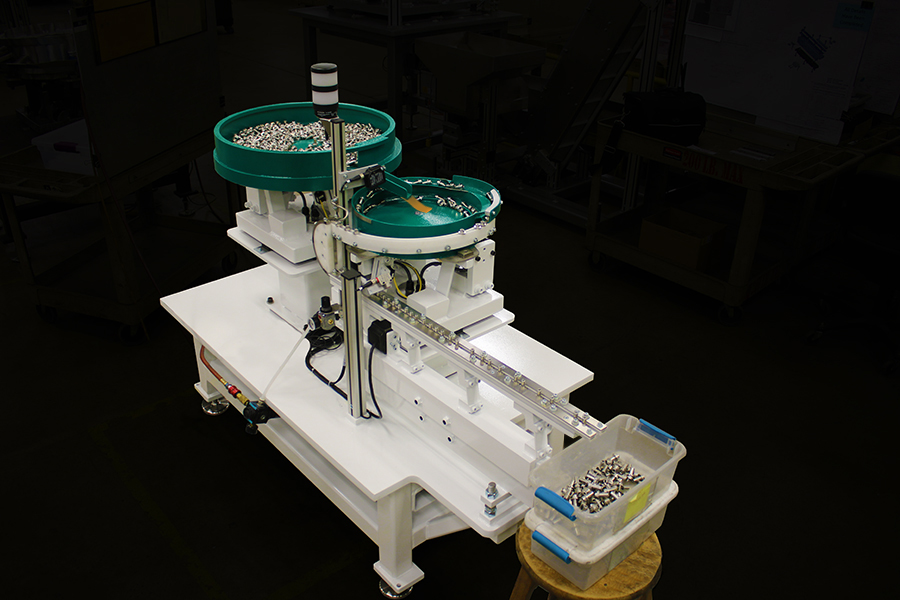

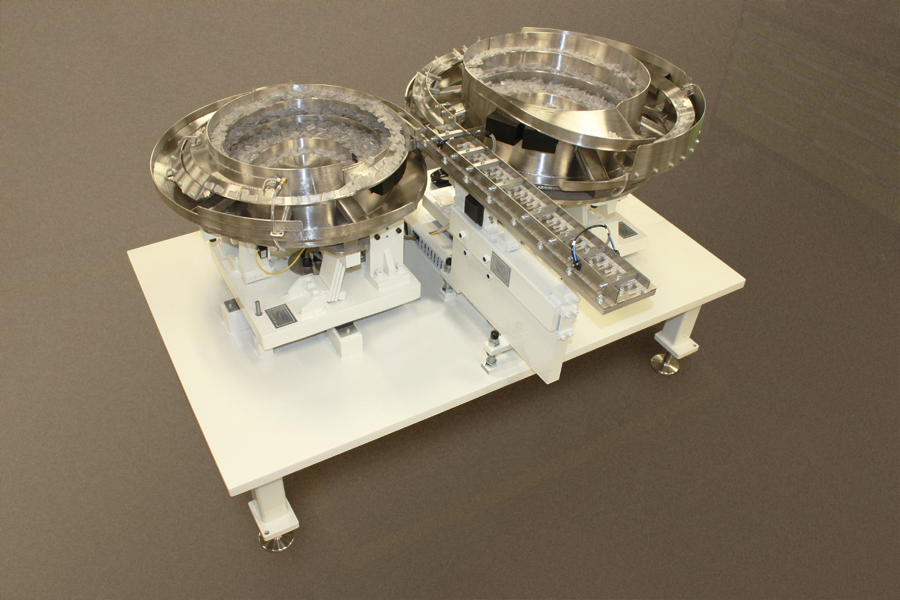

Problem: A medical device manufacturer needed to replace an inefficient feeder system for two caps. The system they had attempted to feed two parts from the same vibratory bowl. The two caps had very different geometries. It caused constant jams in their old feeder....

by Kevin Yaney | Apr 23, 2020 | Uncategorized

Introduction: An integrator located in Montreal, Canada needed a manufacturer to both produce and provide service on vibratory feeder systems. Even though the integrator typically does all of their own parts feeding systems on the automated machinery they produce,...

Recent Comments