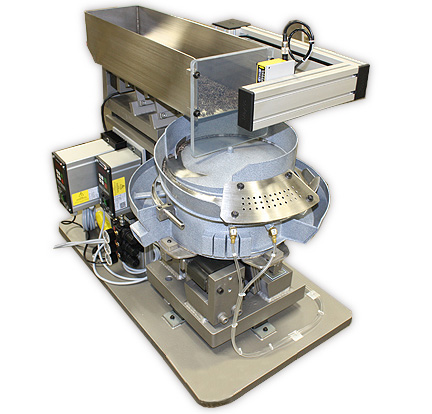

Problem: The customer needed to automate the sorting and orientation of two different small wire springs. This had been performed by hand prior to adding a feeder bowl system to their automation line.

Solution: Fortville designed a single hopper system where the operator fed both springs as bulk parts. The hopper dropped parts into a Surlyn coated vibratory feeder bowl, which in turn, divided the two parts into two lines. The parts were singulated and oriented before being air driven to the next task on the line. By adding the feeder system, the customer was able to automate the task of separating the parts. This sped up their production considerably and reduced human error in the process.

Recent Comments