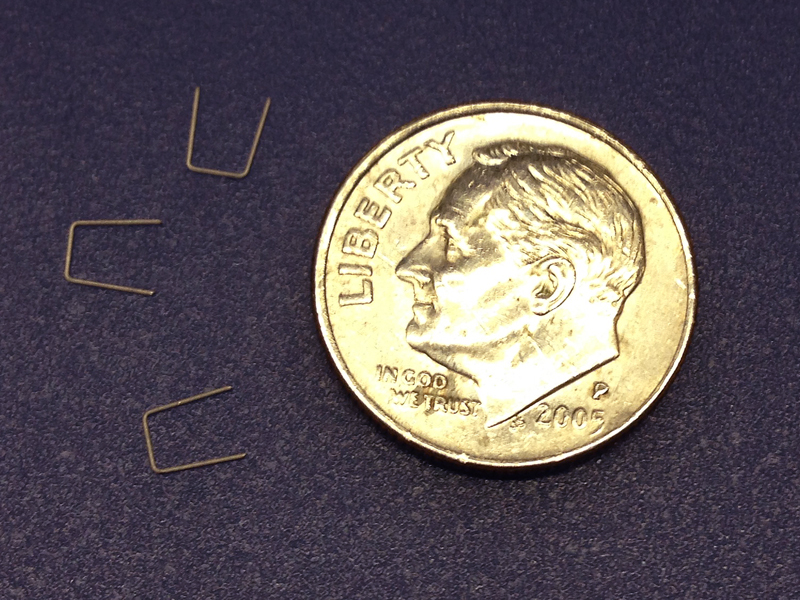

Problem: The customer needed to sort and orient small wire parts (.150″ squares made with .0085″ wire) for high speed automation. They needed a system that would feed and track the parts reliably.

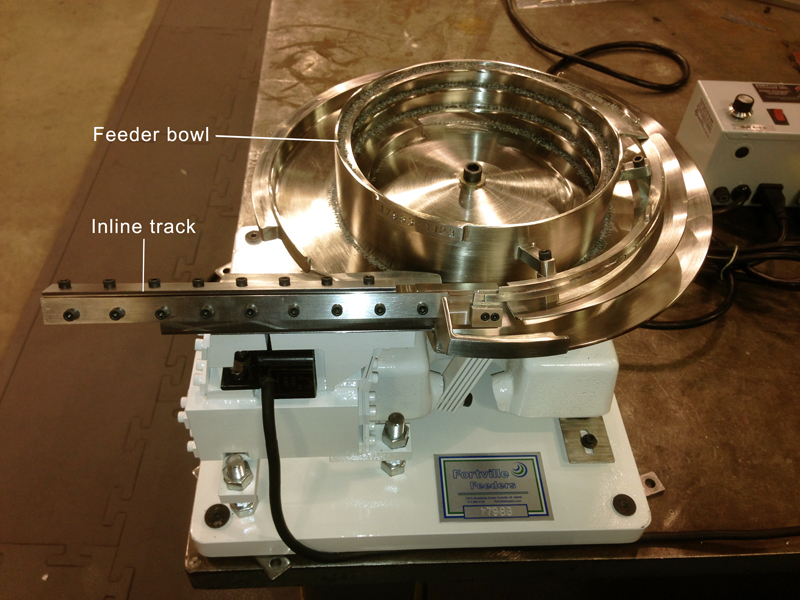

Solution: With any small part, positioning in correct orientation down a track is a challenge. Fortville Feeders built a customized vibratory feeder bowl with an inline tracking system that took into account the lightweight nature of the parts.

Recent Comments