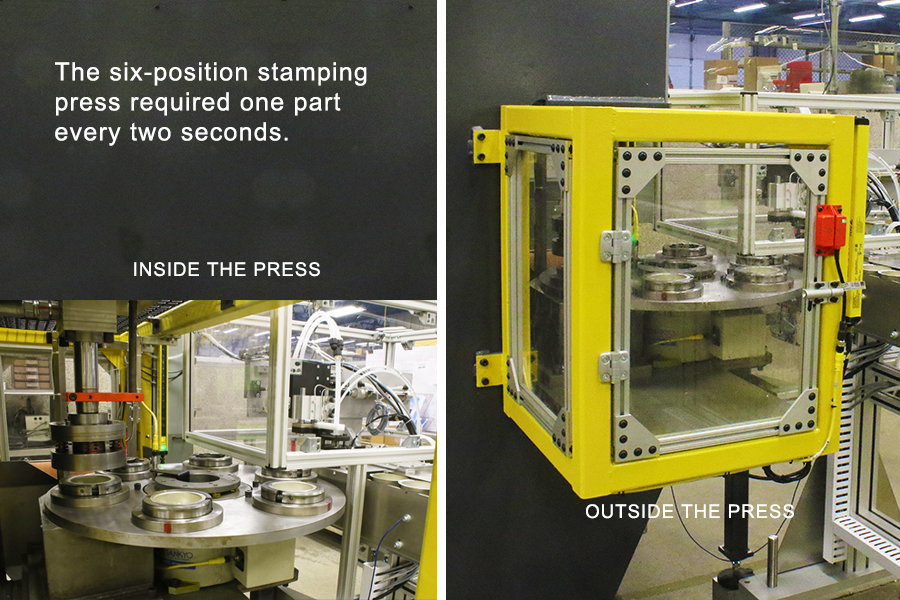

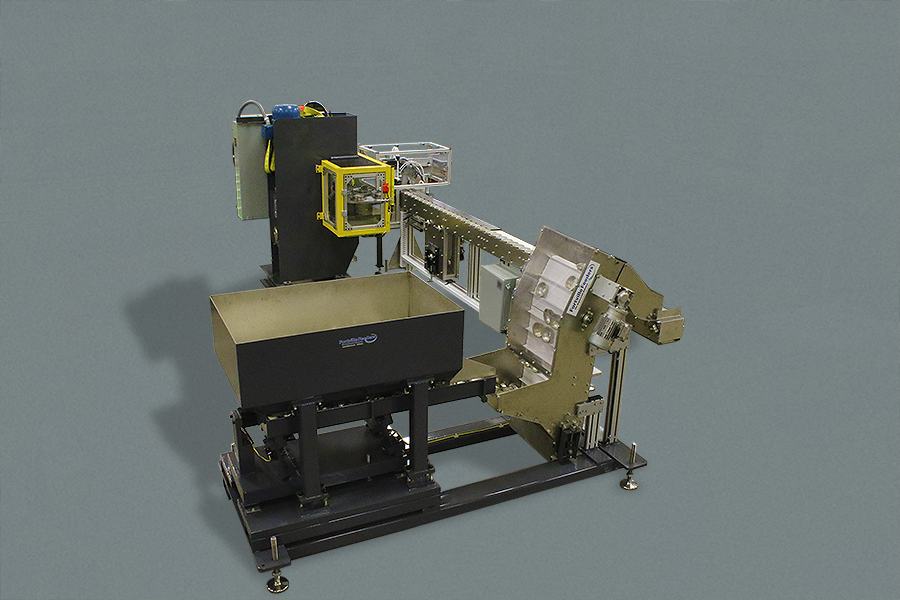

Problem: A manufacturer of storage and shipping tubes was looking for a parts-feeding system that would work with their metal stamping unit. The parts needed to be both loaded and unloaded from the six-position stamping press every two seconds without misfeeding or misorienting the parts. They were looking for an automated system that could be loaded and then left to run unattended.

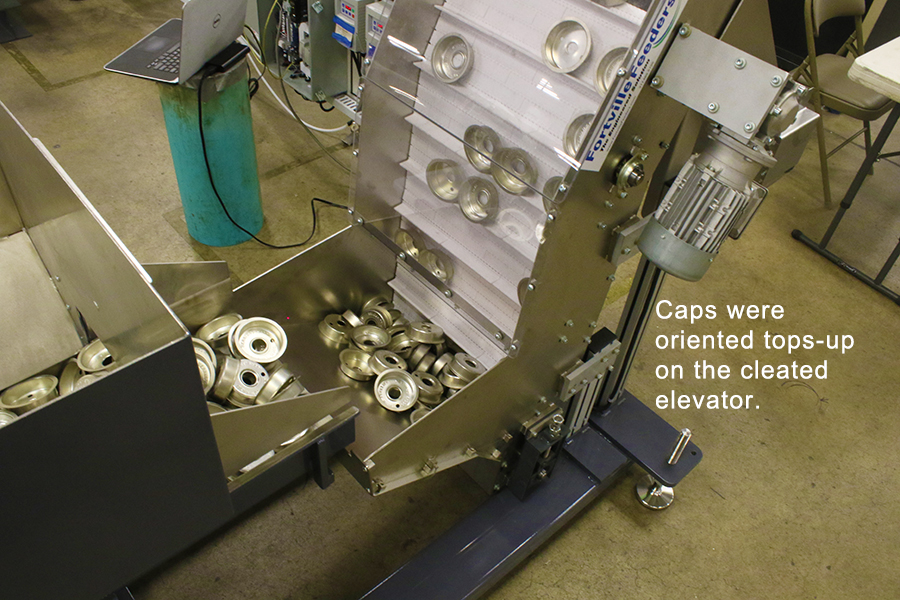

Solution: Fortville always begins with an examination of the parts that need to be fed and comes up with engineered solutions to any problems. In this case, the part was an endcap for a tube. It was important for the caps to be fed facing up without exception. Fortville fed the bulk parts from a live-bottom hopper to a vertical-cleated elevator. The geometry of the parts allowed for proper orientation to happen on the elevator, as a bottom-up cap would succumb to gravity and fall off the 90-degree lift. Only a top-up cap could survive this lift. This simple solution saved additional tooling in the track to get proper top-up orientation.

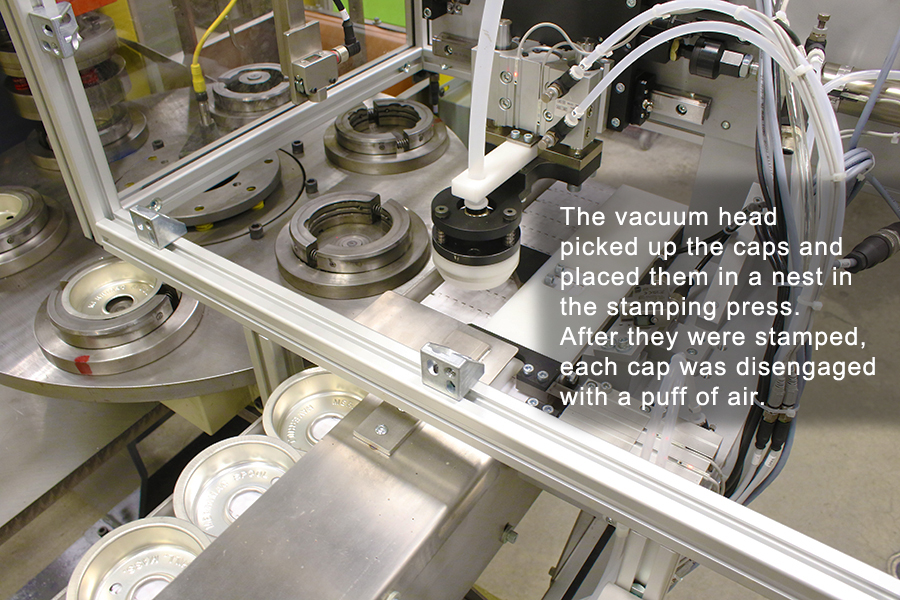

They were then fed down a track that overlapped the front edge of each part to eliminate any misfeeds at the end of the line. Once they arrived at the end of the track, they were picked up by a vacuum head and placed in the press’ nest for stamping. Once they were stamped, each part was disengaged from the nest with a jet of compressed air before moving on to the next automated function.

Fortville Feeders was able to provide a parts feeding system customized to the stamping press that both loaded and unloaded the machine automatically without misfeeding incidents. The hopper could simply be loaded with caps and the machine would run without any downtime.

Recent Comments