Bulk Storage Hoppers

Bulk storage hoppers are designed to

provide easy loading and transfer of parts. We use stainless steel on all our hoppers. None of them are painted or covered with a coating that could chip and contaminate your parts.

We provide solutions for heavy parts, fragile parts, FDA restricted applications, multiple parts and more.

Volume

1/10, 1/2, 1, 2, 3, 5, 7 cubic feet

Options

7″ or 11″ tray

Styles

Standard

Straight Front

Low Profile

Trough Drivers (for heavy duty parts). Cold rolled steel construction

Features

Vibratory

Stainless Steel Construction

Live Bottom (optional)

Hopper Capacity

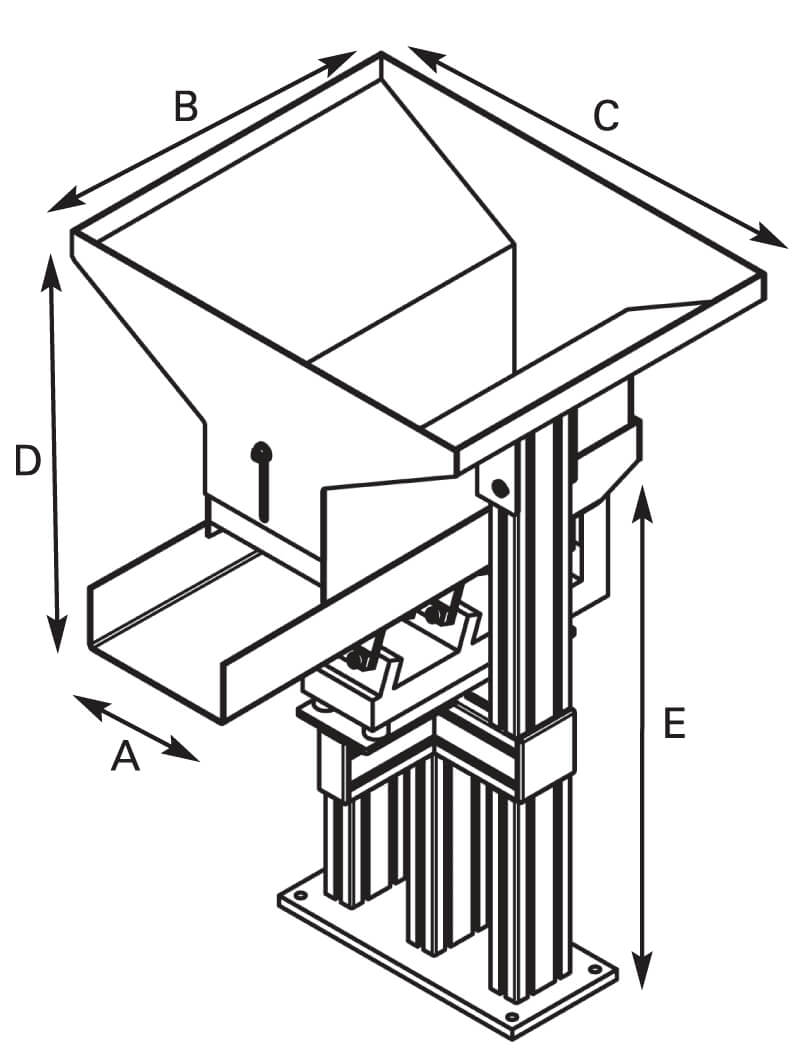

| Cubic Feet | Tray Width A |

BIN Length B |

BIN Width C |

Load Height (from bottom of tray) D |

Load Height (from mounting surface) E |

| 0.1 | 2.75 | 6.00 | 6.00 | 6.70 | 5.25+ |

| 0.5 | 6.50 | 11.00 | 12.00 | 9.00 | 7.11+ |

| 1 MEDI | 7.50 | 17.50 | 22.00 | 14.00 | 7.11+ |

| 2 MEDI | 7.50 | 17.50 | 22.00 | 18.00 | 7.11+ |

| 3 MEDI | 7.50 | 17.50 | 22.00 | 23.00 | 7.11+ |

| 3 MAXI | 11.75 | 17.75 | 28.00 | 17.00 | 7.11+ |

| 5 MAXI | 11.75 | 17.75 | 28.00 | 24.25 | 7.11+ |

| 7 MAXI | 11.75 | 17.75 | 28.00 | 31.25 | 7.11+ |

All dimensions listed in inches. Sizes and specifications are subject to change.

Not finding the right sized hopper in our chart above? We can customize a hopper to meet your needs.

Gondola and Elevator Hopper Conveyor Systems

Our gondola and elevator systems transport

and dispense parts for continuous feeding.

Elevators save space and move bulk parts

quickly and efficiently.

Length

8′ standard, additional sizes are available

Width

8″ standard, additional sizes are available

Styles

Drag-through elevators

Magnetic

Fortville feeders is the

Engineered

Solution

We design Engineered Solutions to solve challenges in your parts feeding automation. This is a partnered process to develop a custom solution for your unique application.