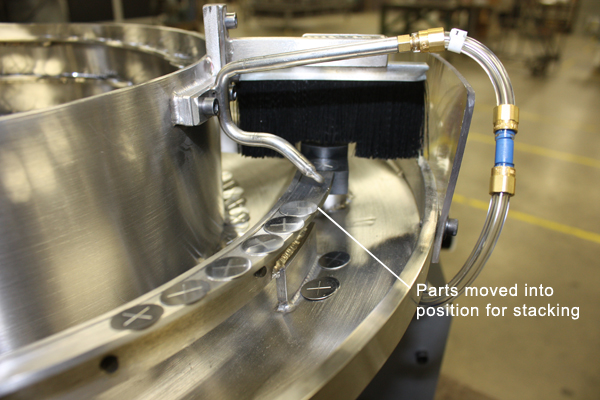

Problem: The customer was dealing with very thin metal parts that would often misfeed in their automated system. They needed a way to supply the parts in an accumulative fashion (edge to edge) without overlapping.

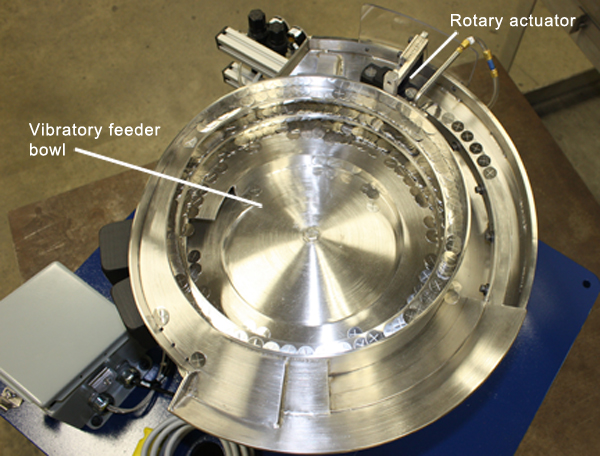

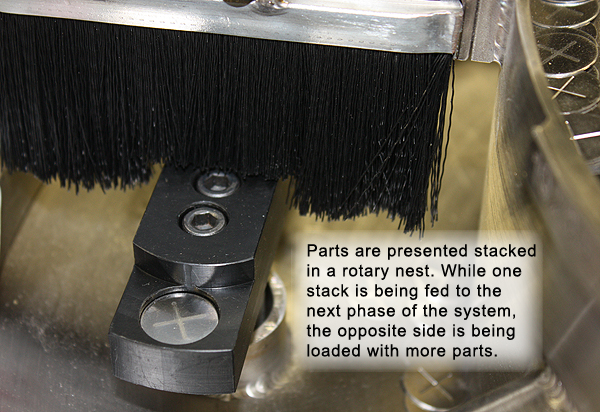

Solution: Fortville designed a vibratory feeder bowl system with a rotary actuator mechanism. The thin parts were moved to a dual nest with two machined pockets on opposite ends of the mechanism. The parts were stacked to a specified height in one of the pockets and then the mechanism rotated so the customer’s tooling could pick up the stack of parts. As one side empties, the other side stacks more parts. This allowed the parts to be fed quickly and accurately without containment that could present overlapping problems.

Recent Comments