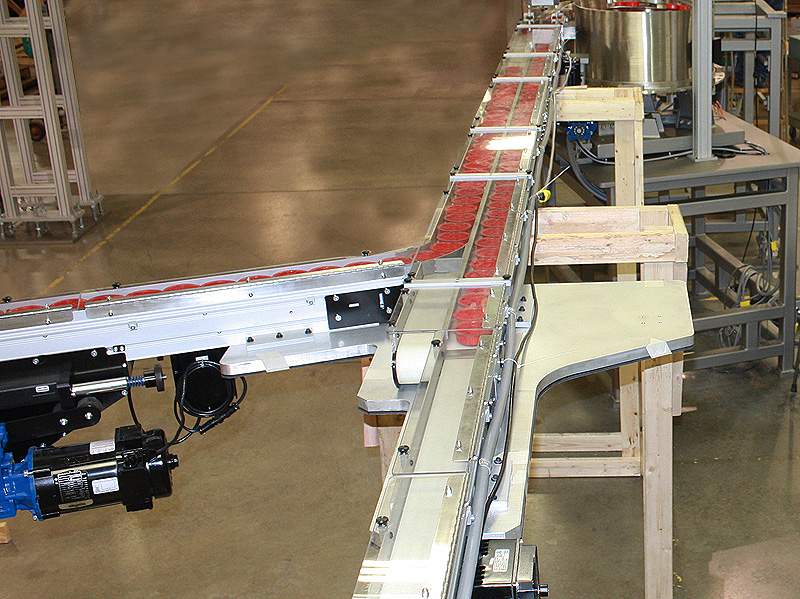

Problem: The customer needed to sort and move bulk plastic caps to two robots for pickup. The parts needed to be moved over 50 feet. However, there was a problem with space. The shop floor needed to be kept clear for rolling equipment and the existing machinery.

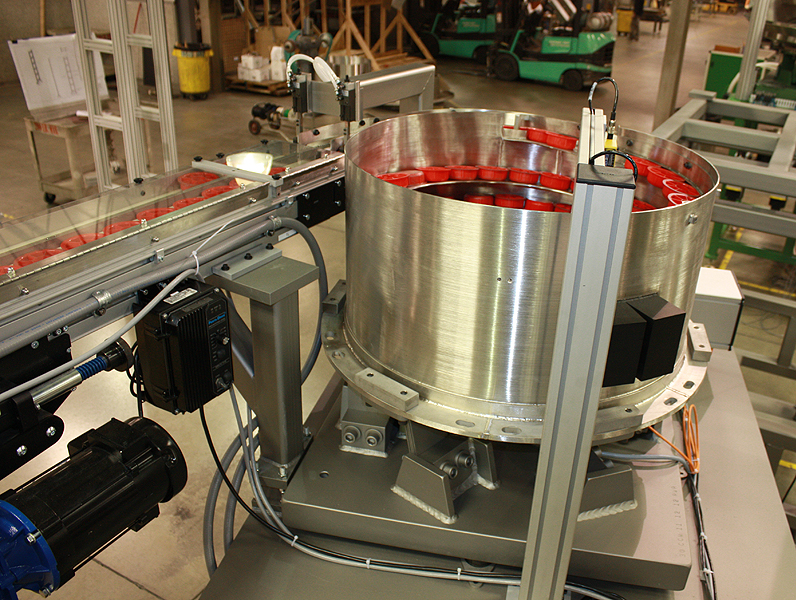

Solution: Fortville designed a feeder bowl with a dual conveyor system. The feeder bowl sorted the parts onto two conveyors which then lifted them up and over the existing equipment, 14 feet off the floor. The parts were positioned on the conveyors for correct orientation. The conveyors were covered with plexiglass to keep extraneous material from falling on the parts. The parts were then discharged down to two pedestal robots on the shop floor.

Recent Comments