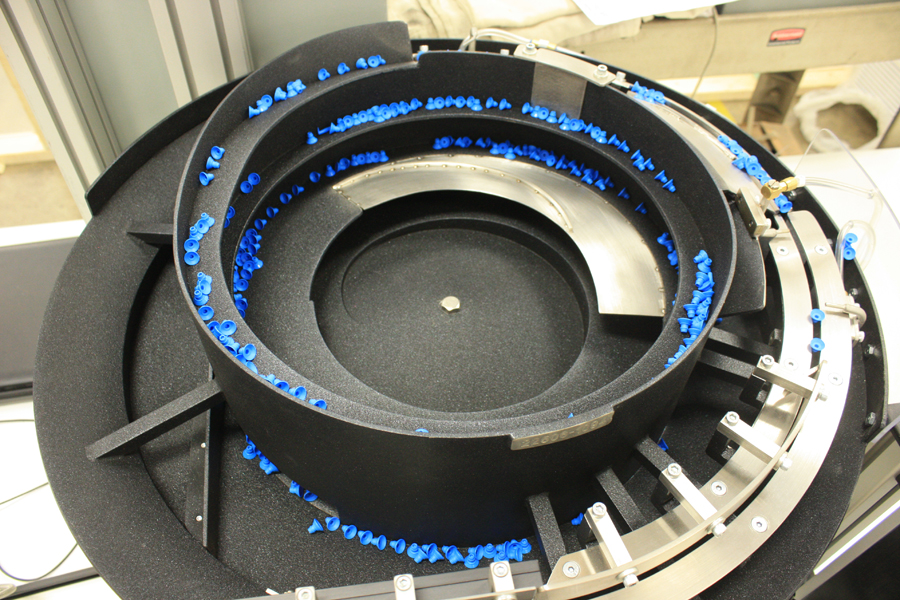

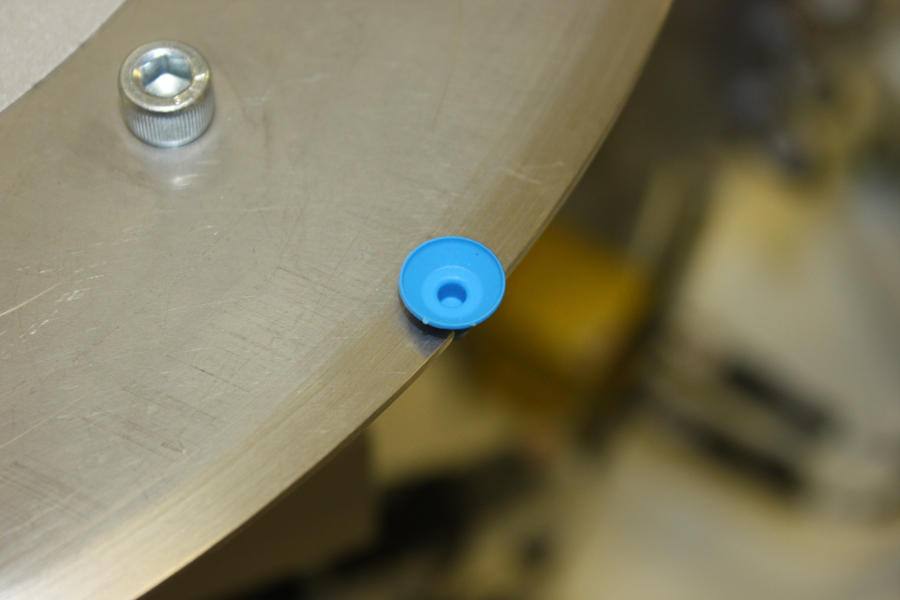

Problem: During the testing and inspection phase of the fabrication process, a problem was discovered. The part was made of a very soft rubber that had a tendency to easily misshape, especially in heat and humidity. It was also lightweight. These two factors would cause the parts to misalign, jam the track, and misfeed the actuator.

Solution: Many feeder systems manufacturers would send a completed-as-specified machine to the customer as is. However, Fortville Feeders is a MAC Certified manufacturer. Testing of custom automation equipment is one of five facets of MAC Certification. MAC Certified manufacturers agree to test and solve problems before their machines are delivered to the customer.

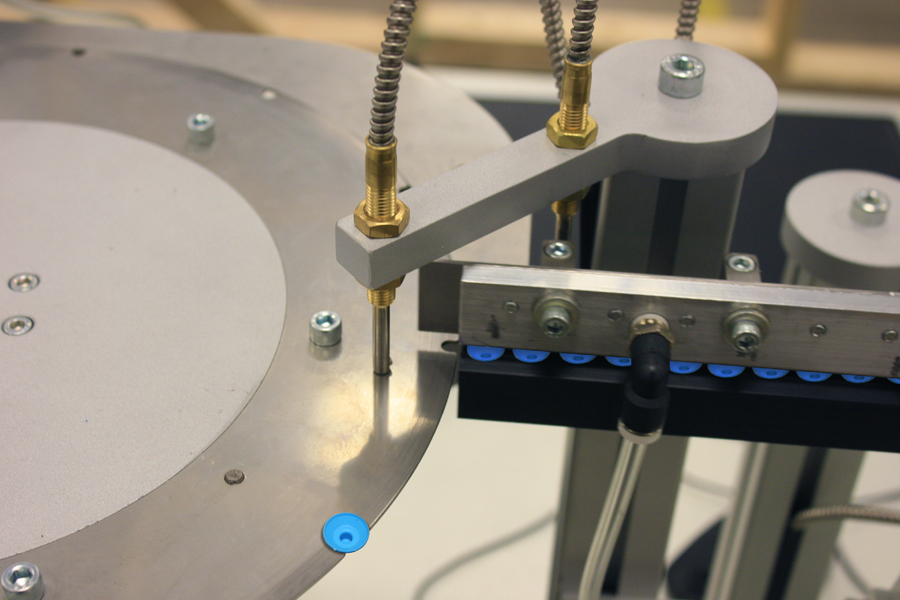

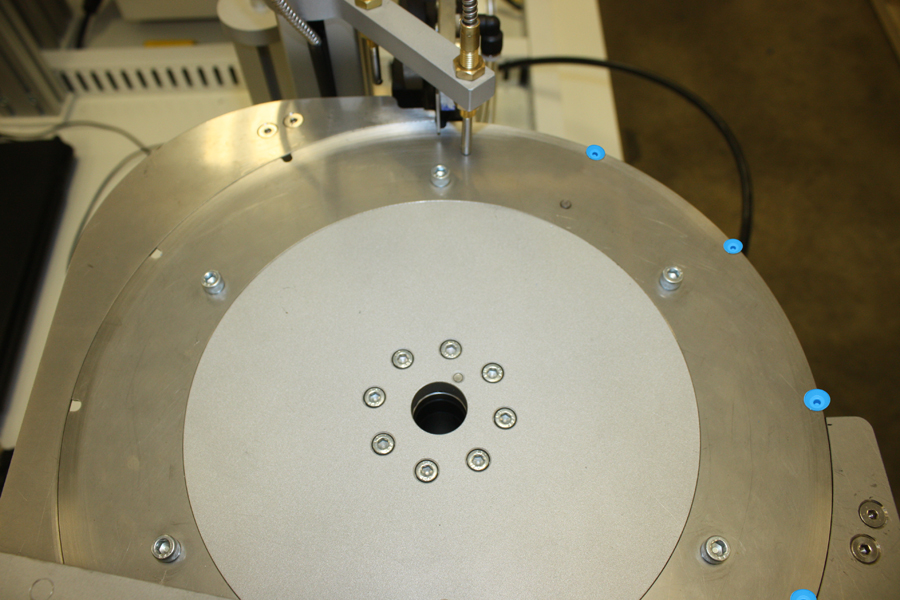

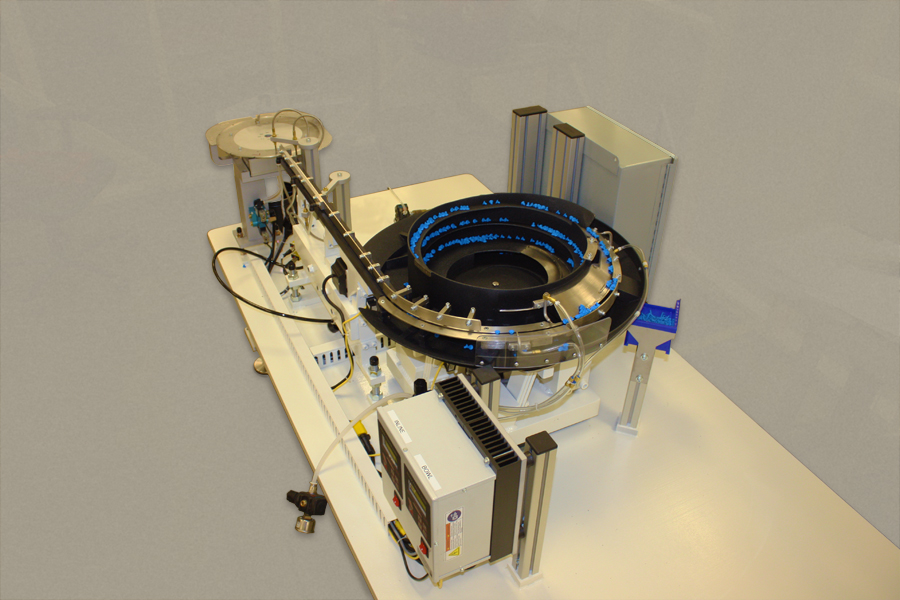

Fortville engineers and toolers worked together to come up with a workable solution. The first step was to isolate the system in a climate-controlled room to eliminate the heat and humidity impact on the parts. They then tested the part for resistance to different types of materials and holding its shape during vibration. They made adjustments to the design and installed a new track that was coated to provide less resistance to the soft rubber. This solved one part of the equation. They also adjusted the vibration levels along the track. This was key in keeping the parts in proper orientation to be placed in the rotary actuator. One more adjustment was made to the pockets of the dial to ensure proper pickup by the robot.

MAC Certification is a continual improvement process for a better customer experience. The lessons learned in one feeder system are applied to others. In the end, the customer was elated to have a feeder system that could handle a very difficult part.

Recent Comments